Introducing the Next-Generation SG8 Sinker EDM with Mitsubishi Electrics’s AI Technology (Maisart) and M800 Series Control System to pursue both…

LEARN MOREWhen it comes to razor-sharp accuracyon heat-hardened materials, nothing beats sinker EDM machines. But there’s more to efficient, productive machining than meets the eye.

Advanced controls,on-board automation capabilities,and a superior power supply that keeps you moving and producing with less downtime make sinker EDM machinesfrom MC Machinerythe ideal choice for tight-tolerance applications,including die and mold.

There are tons of options for unrelenting, unbeatable precision when and where you need it—just a few scrolls down.

Introducing the Next-Generation SG8 Sinker EDM with Mitsubishi Electrics’s AI Technology (Maisart) and M800 Series Control System to pursue both…

LEARN MORE

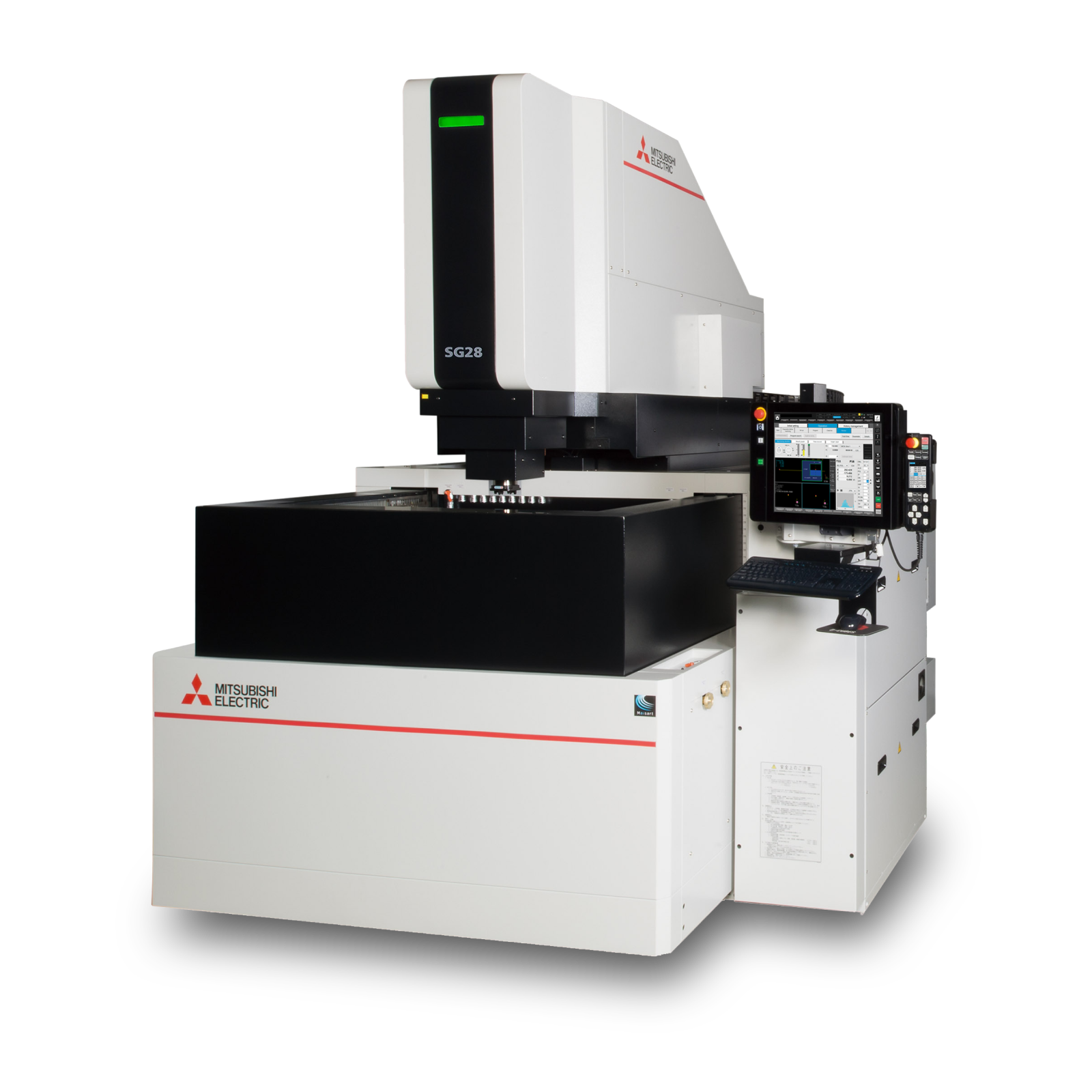

The Mitsubishi SG28 sinker EDM, featuring Mitsubishi Electrics’s AI technology and M800 Series control system, optimizes performance, improves productivity, reduces…

LEARN MORE

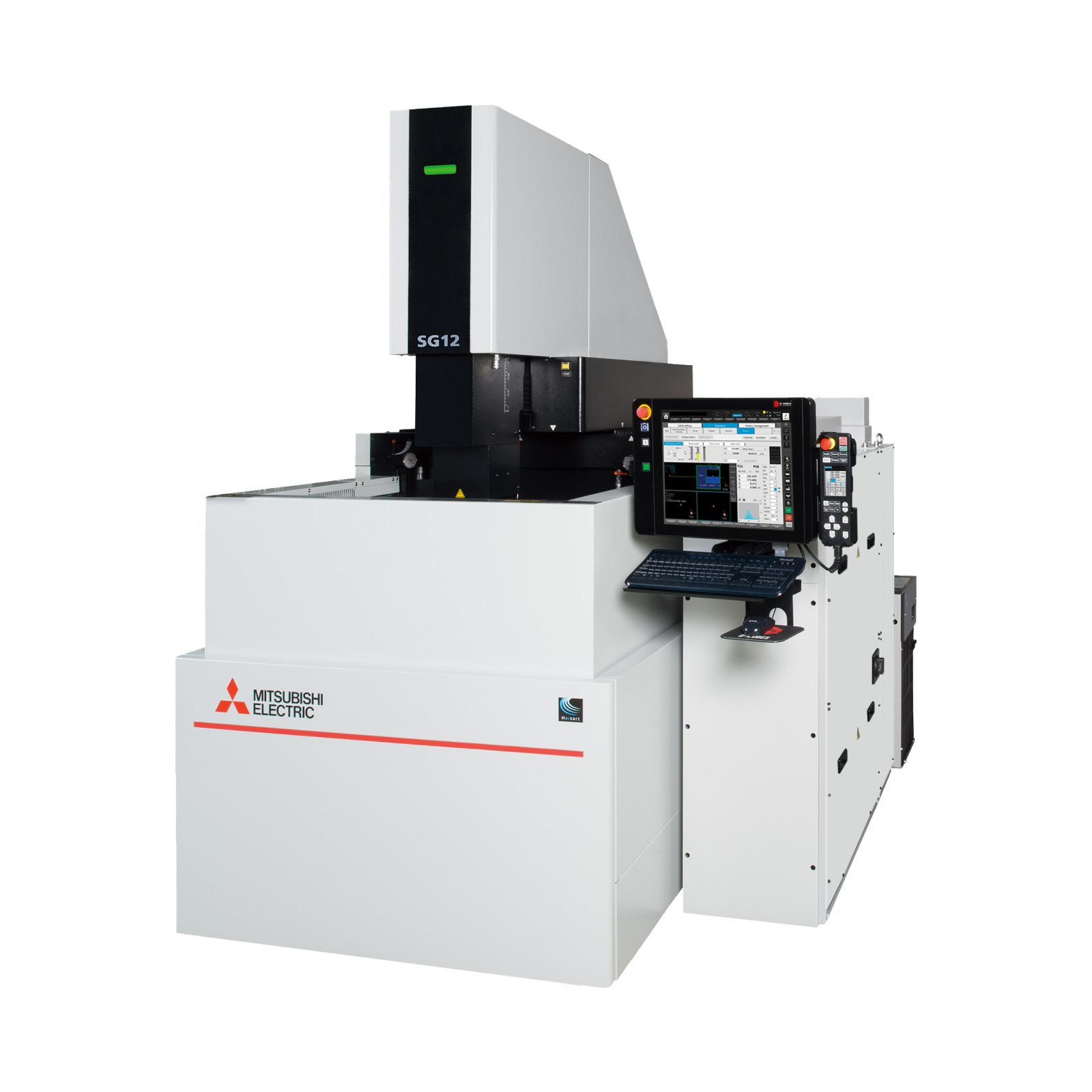

Introducing the Next-Generation SG12 Sinker EDM with Mitsubishi Electrics’s AI Technology (Maisart) and M800 Series Control System to pursue both…

LEARN MORE

An artificial intelligence-infused powerhouse that brings serious smarts to tight-tolerance machining.

LEARN MORE

An AI-infused powerhouse that brings serious smarts to tight-tolerance machining.

LEARN MORE

High-accuracy, high-grade Sinker EDM you can trust for micro-fine finish, mold & die, or small-hole applications.

LEARN MORE

With a larger-than-standard working tank for larger and taller parts, the EA28V-LS lets you accomplish even more.

LEARN MORE

An AI-infused powerhouse that brings serious smarts to tight-tolerance machining.

LEARN MORE

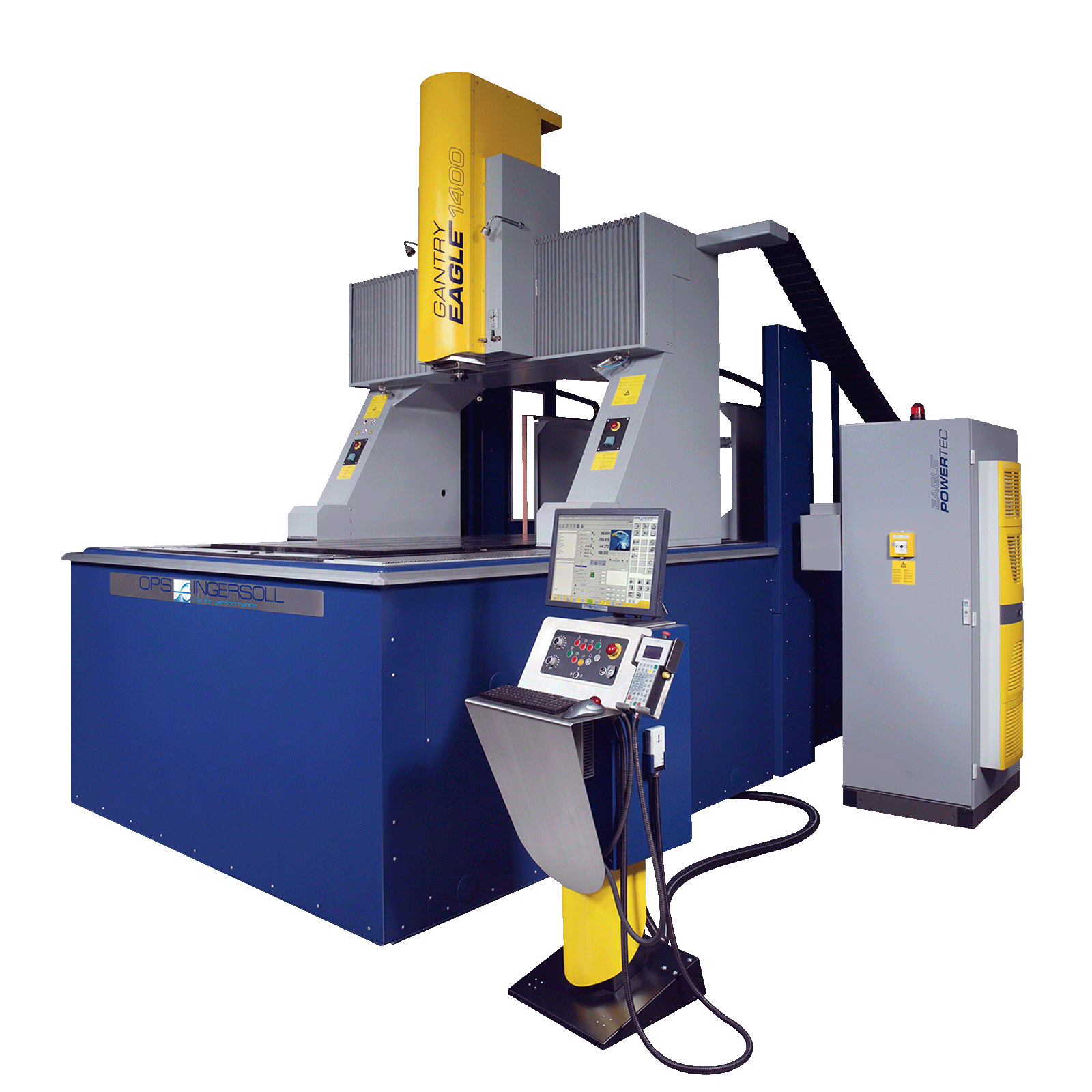

Best in class for large part and molding applications – low electrode wear and fast cycle times create an excellent…

LEARN MORE

A larger work area, reliable performance, low electrode wear, and fast cycle times create the best value in the industry.

LEARN MORE

For when the utmost in exacting precision is required, the Eagle G5 Precision rises to the challenge.

LEARN MORE

A true workhorse for all large mold shops – the best electrode wear and cycle times create an excellent ROI.

LEARN MORE