Customer Case Study: Laser

Mill Finish Industries, a metal fabricator in Brampton, Ontario, is using its new Mitsubishi SR-F fiber laser to produce sneeze guards, social distancing signs, and medical-grade stainless-steel tanks.

Mill Finish Industries President JR Sehmbi said the company started manufacturing sneeze guards in March after a local hospital requested them. The company is currently making about 80 sneeze guards weekly for U.S. and Canadian retailers, restaurants, and medical offices. The Mitsubishi laser is used to make the guard’s steel legs.

The social distancing signs, made from aluminum and stainless steel and cut using the fiber laser, have been so popular with grocery stores and medical offices that the 100 it is producing weekly barely meet demand.

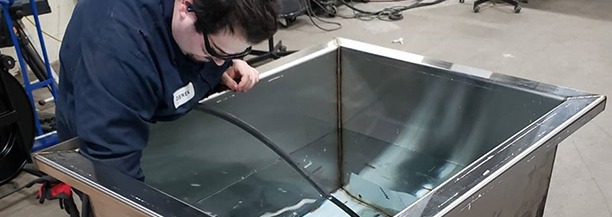

The company has made 18 stainless steel tanks for Canadian pharmaceutical companies since mid-March, using the fiber laser to cut the complete tank assembly.

Sehmbi purchased the new Mitsubishi fiber laser in February and uses it to fabricate metal components for automotive, aerospace, and elevator companies, among others.

“Mitsubishi’s commitment to us over those years is priceless and their continued support was a big selling feature,” Sehmbi said. “The laser itself is a workhorse. It is consistent—I never have to worry about condition adjustments. I can jump from 20-gauge stainless all the way to half-inch stainless and the machine cuts flawlessly. I have been a CO2 laser owner for 10 years; this was my first fiber and smallest laser. The 3Kw fiber proved to be a perfect match for our company. It was very easy to pick up on and learn. I feel as though the machine is so well set up from the factory, it leaves nothing for the operator to do other than hit the start button.”