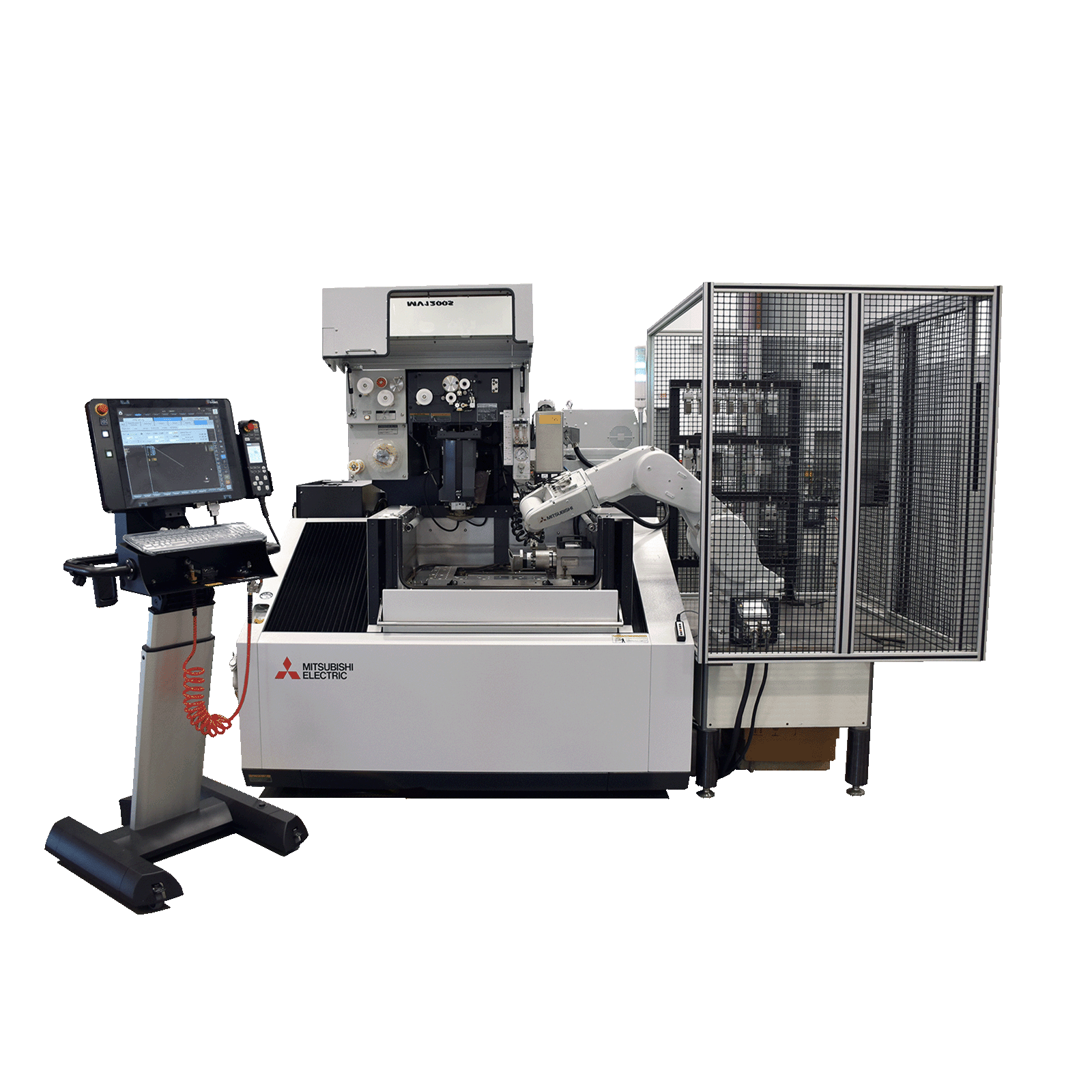

Built for a single machine or multiple this is an adaptable automation unit with 4th rotary and 4th/5th rotary packages. This robot is made for years of around the clock production and increased profit margins with less manpower.

With EDM automation from MC Machinery Systems, customers can greatly increase throughput and maximize their resources.

EDM automation cells may employ OPS Ingersoll 5-Axis or Roku-Roku high-speed vertical milling machines and robots, for example, to speed electrode production and replacement and allow for complete lights-out operation. Our Wire EDM automation solutions add the capacity to load and cut workpieces in immediate succession—loading and unloading them automatically.

A new world of increased throughput, cost efficiency, process optimization, and more is waiting for you. Let’s get to work automating your production requirements today.

From small fabrication shops to massive lights-out operations, our laser automation experts will work with you to determine the right combination of machines, storage, and material handling.

Mitsubishi laser automation is modular and flexible, so we can grow with you. From a simple dual pallet machine to automatic part sorting and material inventory systems with many options in-between, the only limits to how you can improve your productivity and profit margins is your own imagination.

Thanks to our wide range of options—including configurations that require 30% less floor space than typical laser automation setups—we have solutions for any application.

If timelines and deadlines are pressing in on your production line, a fully automated press brake solution can go a long way toward relieving some pressure—on both your bottom line and your peace of mind. But how?

A press brake fitted with a Mitsubishi automatic tool changer (ATC) stands out in all kinds of ways.

Manage and optimize your workflow to save time, money, and human effort. Avoid and actively prevent costly downtime and product defects. Fine-tune your shop to meet the needs of the day with unmatched programmability, functionality, and real-time, cloud-based machine insights. Whatever the challenge, there’s an automation solution that can help.

With milling automation from MC Machinery Systems, customers can greatly increase throughput and maximize their resources.

Milling automation can keep your process in house, improve process control, and significantly reduce lead times compared to outsourcing. Milling automation solutions are based on your unique needs and goals and pay for themselves quickly due to lower operating costs, reduced lead times, increased output, and more.

A new world of increased throughput, cost efficiency, process optimization, and more is waiting for you. Let’s get to work automating your production requirements today.