ATC SERIES

Real-time information from this game-changing tool changer lets any press brake operator perform better.

When each new day brings on new projects—and new challenges—there’s finally an option for making sure your bending department is always one step ahead.

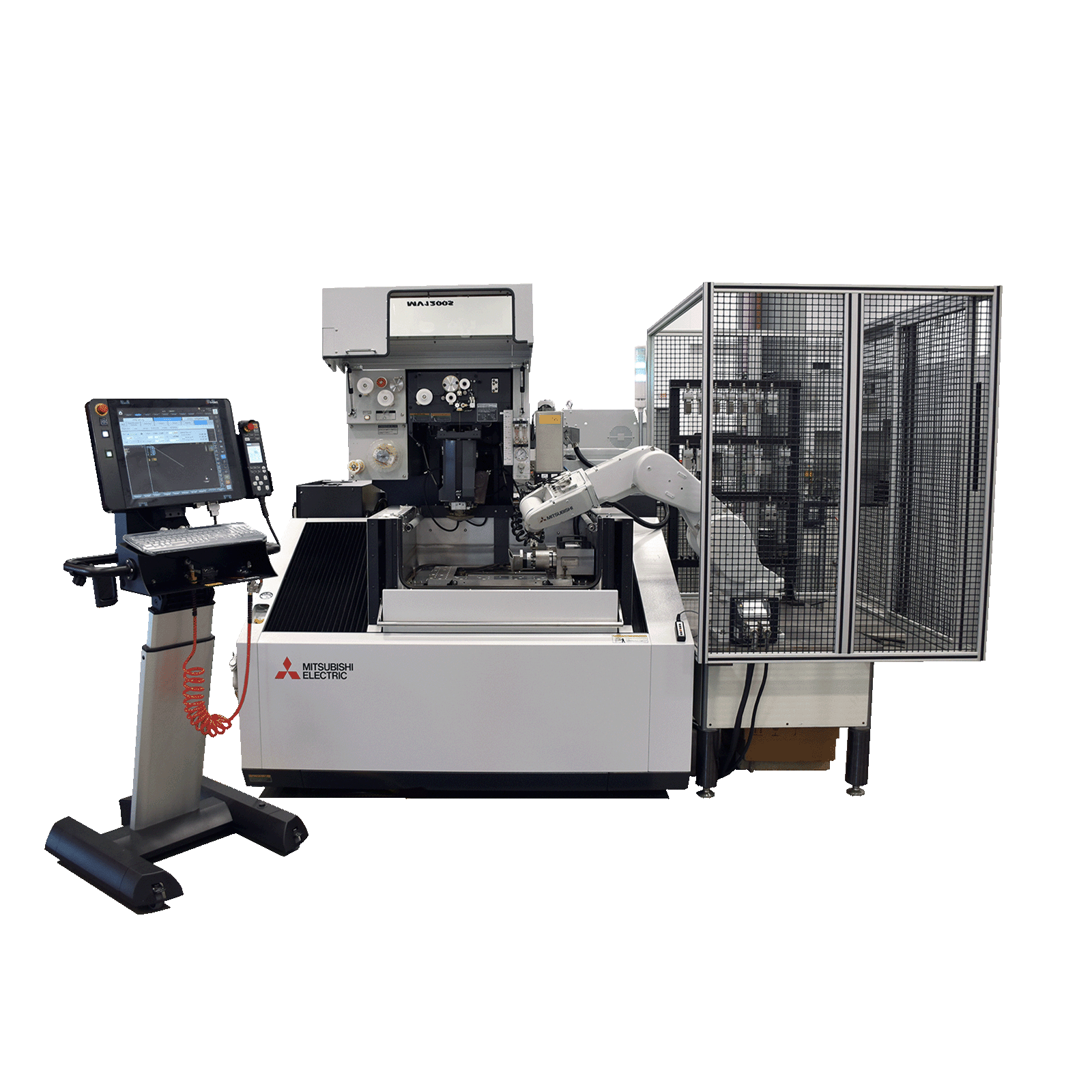

Featuring fully automated tool setup/manipulation/tool cleaning/guidance, the ATC can be fitted to most BH series MC Machinery press brake and will automatically swap in and change out tools while the operator tends to other tasks—further reducing the setup time to mere minutes. Due to the large, single manipulator, larger tools can be picked and placed inside of tool setups to reduce setup time of similar tool staging. During the tool-changing process, the manipulator automatically cleans the bed surface and tooling, removing an additional process seen in other ATC applications.

Simple, accessible, and remarkably efficient, the ATC series from Mitsubishi can help shops excel at the high-mix/low-volume work that’s so common in today’s modern manufacturing environment.

MAXIMIZE EFFICIENCY & PRODUCTIVITY

- The ATC brings further production increase and reduction of setup time to the BH Dual Drive series. The ATC 32 was developed by reviewing tool-changing applications in the market and bringing greater variation of solutions to the market to support customers’ goals of improved efficiency.

USER-FRIENDLY OPERATION

- Utilizing both the VIDERE operator support system and the ATC to automatically change the tooling provides the ultimate solution for improved production and increased efficiency in the bending department. Supporting new operators or more seasoned brake operators with information in real-time in front of the operator while changing the tooling automatically is an unprecedented solution never offered to customers until today.

BUILT TO KEEP YOUR SHOP FLOOR BUSY

- The operator can choose to use the ATC when using programs or, if tools are not available in the ATC, will wait patiently for the next job to load tooling. Plus, with the ability to create new programs directly at the control or offline through DiamondBend, the ATC is flexible enough to work with your operators—never against them. That means less downtime and less time spent troubleshooting, so everyone can keep working effectively every day.

CAPABILITIES:

- Tool storage – Customers now have options ranging from 107.28’ (32m) up to 170.60’ (52m) of tooling, allowing the greatest variation of tooling storage ranging from high runner V openings to specialized tooling, such as hemming or offset tooling

- Automated tool setup & cleaning – The ATC will automatically change the tooling while the operator is free to perform other tasks further reducing press brake setup time. Up to 50 mm (2”) v-die opening and 500mm (19.7”) tool lengths can be used in the ATC. The manipulator is also equipped with a cleaning device that cleans the tools and bed surface automatically during tool changes.

- Tool usage flexibility – Machines equipped with the ATC are not limited to using tools from the tool changer’s storage. The operator can use the machine as a stand-alone press brake, as well as an automated system. This gives the operator flexibility for hot jobs, one-offs, or jobs that utilize tooling not stored in the tool changer allowing for the greatest flexibility of any other ATC system.

- The Diamond BH “dual drive” system controls high-speed up/down movement with a ball screw and bending movement by the servo-hybrid piston system for unbeatable functionality.

- The dual drive system allows high-speed down movement at 200 mm per second with high repeat-stop accuracy while still offering energy savings thanks to an assist device that stores the energy of down movement for the industry’s fastest cycle time 2.3s.

- The ram floats on a gas cushion, thereby greatly diminishing the weight to return the ram to the top of the stroke, resulting in lower operational costs for greater cost-efficiency.

- Ram cylinders powered by AC servo motors with 1-micron repeat accuracy and combined with a back gauge, accurate down to 4 microns, the BH Series delivers positioning accuracy unparalleled in the industry, part after part.

- With automatic thickness detection & compensation, angular irregularities are minimized due to material thickness with no added options or external measurement devices needed; the BH series holds tolerances some machines can only hope to do with angle measurement systems.

COMPONENTS:

- Dual-drive hybrid (ram positioning by electric ball screw and hybrid piston system) with highly stable repeat accuracy (1-micron repeat accuracy) +001mm

- High-speed dual-drive hybrid (fastest cycle time in its class)

- Large stroke and open height

- Patented automatic micro-wedge crowning system (standard)

- Standard 5-axis back gauge on 2.5/3m (optional 7- & 9-axis back gauges available)

- Standard 7-axis back gauge on 4m (optional 9-axis back gauge available)

- LED lighting over the back gauge and front work area (standard)

- Pulse handle with axis control & bending support (standard)

- 5” X-axis max gauge distance (4-micron back gauge repeat accuracy) +0.004mm

- Simple up/down foot pedal safety system (standard)

- Interlocked rear access gate (standard)

- Mitsubishi servo amplifiers and motors

- One-touch European tool holders (standard) – WATCH VIDEO

ON-BOARD PRODUCTIVITY:

- Automatic thickness detection/compensation capabilities for accurately measuring part thickness on the fly

- Work efficiency analysis capabilities to ensure you’re always working at peak production

USER INTERFACE:

- USB & Lan peripheral interfacing

- CNC control with 22” multi-touchscreen LCD display with 3D simulation, 2D/3D draw functionality, and custom multiuser & multilanguage interface

SYSTEM INFORMATION:

- Microsoft Windows operating system (16GB)

- Large program capacity (64GB) with a comprehensive tool library

OPTIONAL COMPONENTS:

- Angle measurement

- Sheet followers (75 kg and 150 kg)

- Sheet supports

- Moveable foot pedal

- Tandem foot pedal

- Laser finger guarding

- Extra CNC back gauge axes (up to 9 axes)

- Hydraulic clamping from Wila and Wilson

- Back gauge touch sensors

- Tooling packages from Wila, Wilson, and Mate

- Interlocked side gates over the C-frames

- American segmented upper punch holders

- Small segmented European punch holders

- DiamondBend offline programming software – WATCH VIDEO

- Automatic tool changer

- VIDERE operator support system

- Increased throat

- Increased open height

- Bar code reader

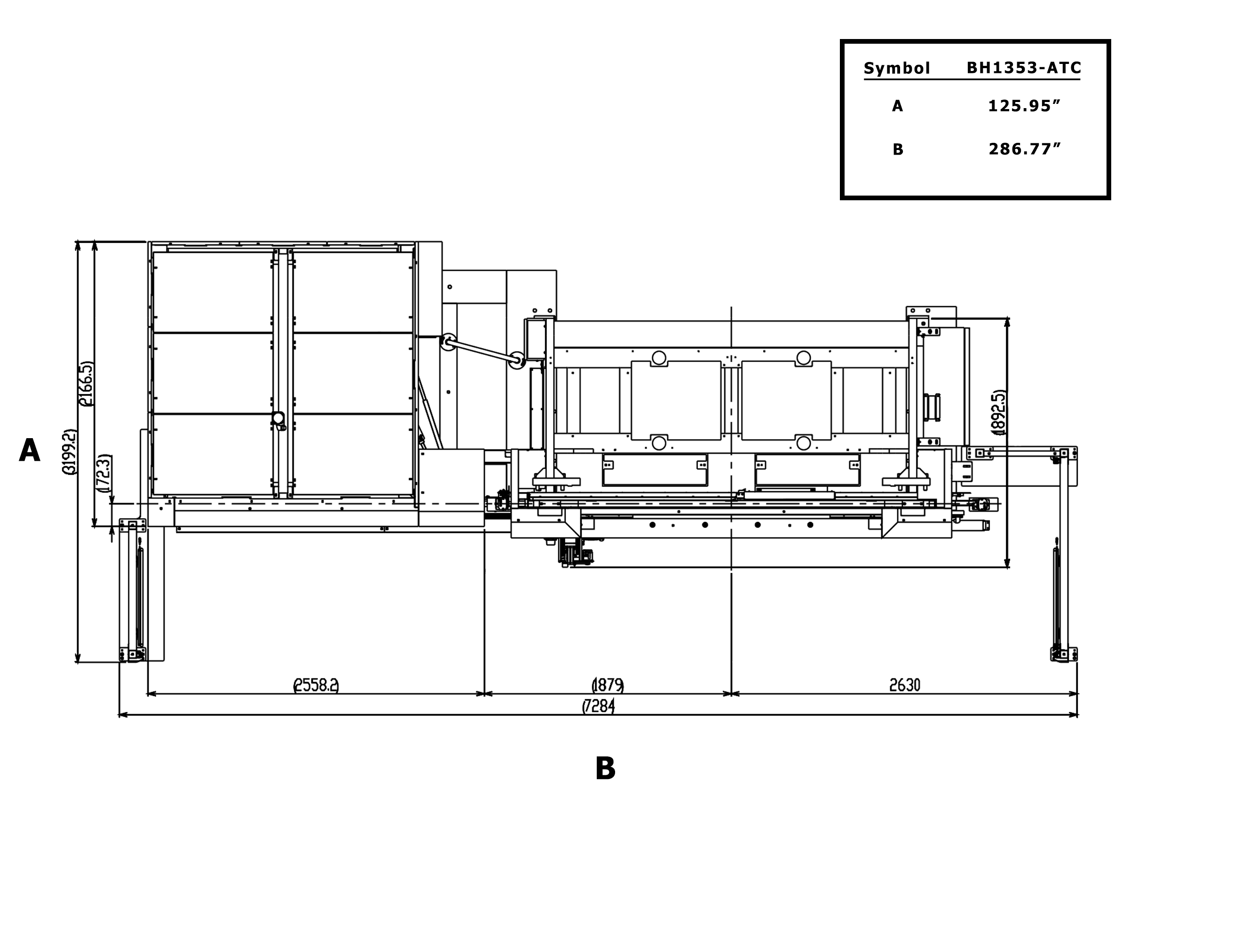

| AUTOMATIC TOOL CHANGER | ||||||

| Number of Tool Storage | 32m section | 52m section | ||||

| Punch Storage | Punch 3 rack 4 cassette (12m) | Punch 5 rack 4 cassette (20m) | ||||

| Die Storage | Die 4 rack 5 cassette (20m) | Die 7 rack 5 cassette (32m) | ||||

| Total Storage | 32 meter | 52 meter | ||||

| Available Machine Listing | BH13530 | BH18530 | BH25030 | BH18540 | BH25040 | |

| Tool Layout Length mm (in) | 20 (.787) ~ 3060 (120.472) | 20 (.787) ~ 4060 (159.842) | ||||

| Tool Layout Range mm (in) | -1530 (-60.236) ~ 1530 (60.236) | -2030 (-79.921) ~ 2030 (79.921) | ||||

RELATED SOLUTIONS

-

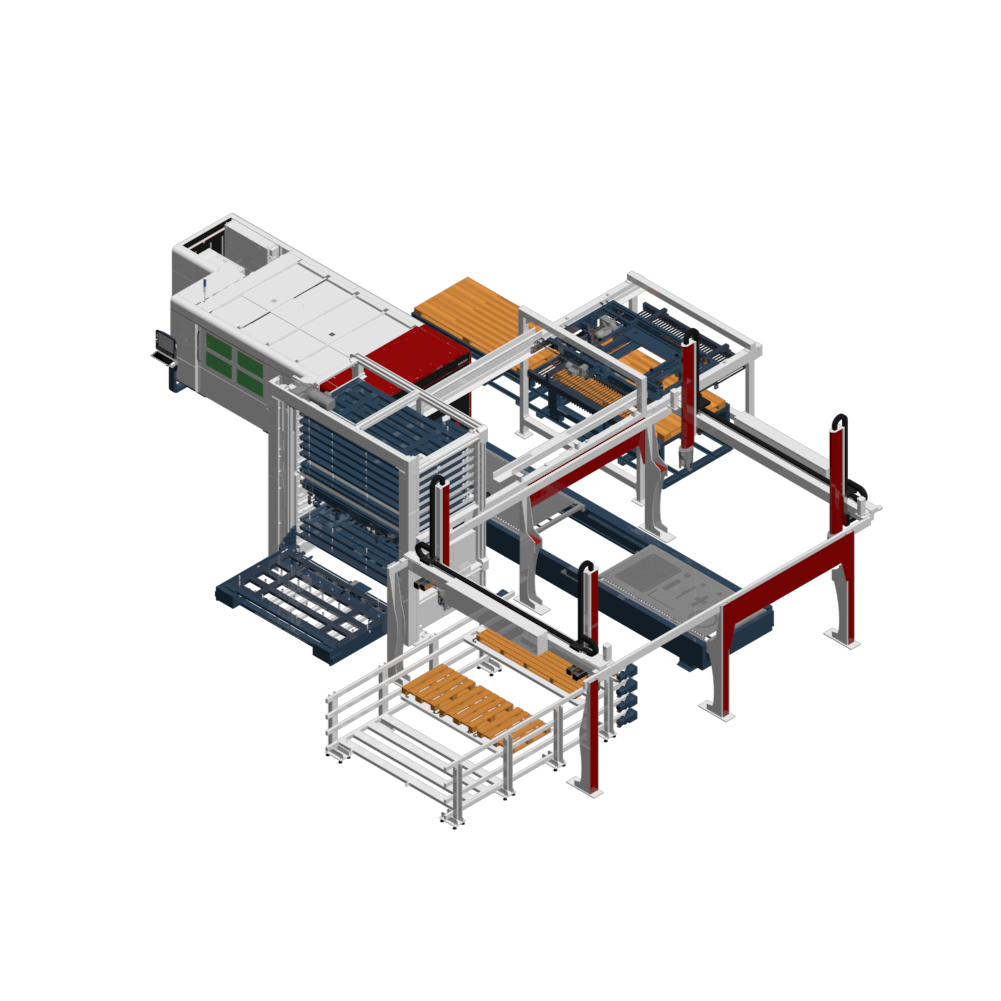

EDM AUTOMATION

The ultimate solution to improve throughput, increase production, reduce manpower, and be more competitive.

learn more -

LASER AUTOMATION

Leave your bottom line beaming.

learn more -

PRESS BRAKE AUTOMATION

Stretch your throughput capacity to new levels.

learn more -

MILLING AUTOMATION

Increase throughput and maximize your resources.

learn more

-

"Ever since we’ve had the (SmartFlex Element Type R) automation tower, it has been an absolute game changer. I think that if you don’t have an automation system on your laser, you are wasting so much opportunity, especially if you’re looking to add additional work to your machine."

Blake Hamar, President of Cali Raised LED Read customer success story -

"Thanks to our advanced manufacturing techniques, we are able to keep up with demand and keep products in stock where our competition can't."

Blake Hamar, President of Cali Raised LED Read customer success story