SMARTFLEX RAPID TOWER

Industry-leading load/unload cycle time and plenty of raw material storage.

A good automation system is one of the most effective ways for any machine shop to reliably send more finished products out the door than ever before.

With an industry-leading 52-second (3015) load/unload cycle time, this machine is quick. That’s why we named this automated sheet loader, the SmartFlex RAPID.

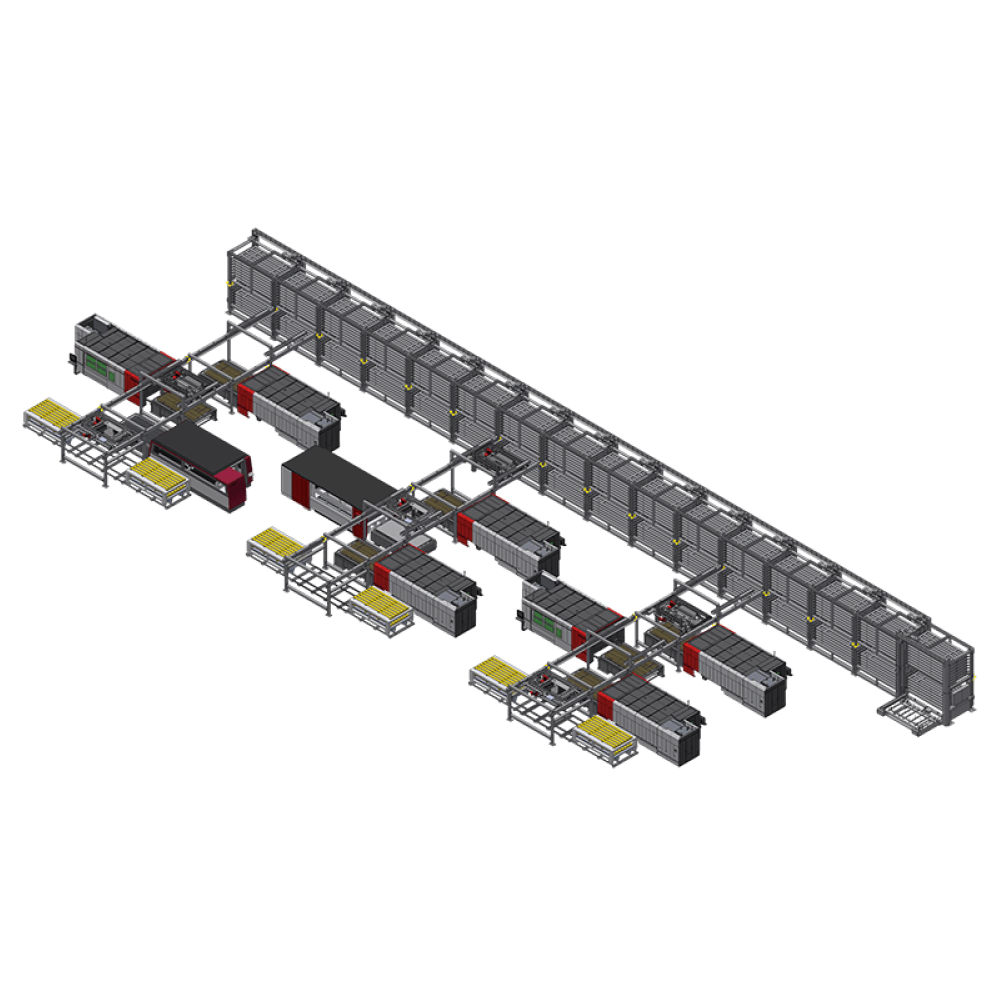

With intelligent, fully independent load and unload units that can easily support up to four lasers on the same line, and with dual-automated SmartStation carts for both load and unload—each capable of supporting 11,000 lbs. of raw material or finished goods—the SmartFlex RAPID is as powerful and versatile as it is fast.

SmartFlex RAPID packs all the punch you need to make your dreams of quick, reliable, cost-efficient production a reality.

Our RAPID Tower maintains all of the advanced features and speed of our RAPID Base with the added ability to store an incredible amount of raw material with a standard 8 shelves. It can be configured with as many as 46 shelves with multiple towers and can be serviced by up to 3 lasers on a single line.

BUILD YOUR PERFECT PRODUCTION LINE

- Our laser automation line is fully modular, giving you and your shop the perfect opportunity to create a machining and fabrication solution that’s custom-built to your exact specifications. And with configurations that require up to 30% less floorspace than other setups, designing the setup that’s right for you has never been easier or more cost-effective.

PRODUCTIVITY THAT’S GOOD TO GROW

- From small fabrication shops to massive lights-out operations, our laser automation line comes ready with a wide range of options that make it a great fit in nearly any scenario.

EXPERT INSIGHTS INCLUDED

- Not sure where to get started? Not to worry. Our laser automation experts will work with you to determine the right combination of machines, storage towers, product carts, and break-in stations. Together, we’ll help you create an adaptable, future-forward solution you can rely on to meet the needs of today and the challenges of tomorrow.

The SmartFlex RAPID automation system is a robust, modular productivity platform that can be easily altered and augmented—all at your command.

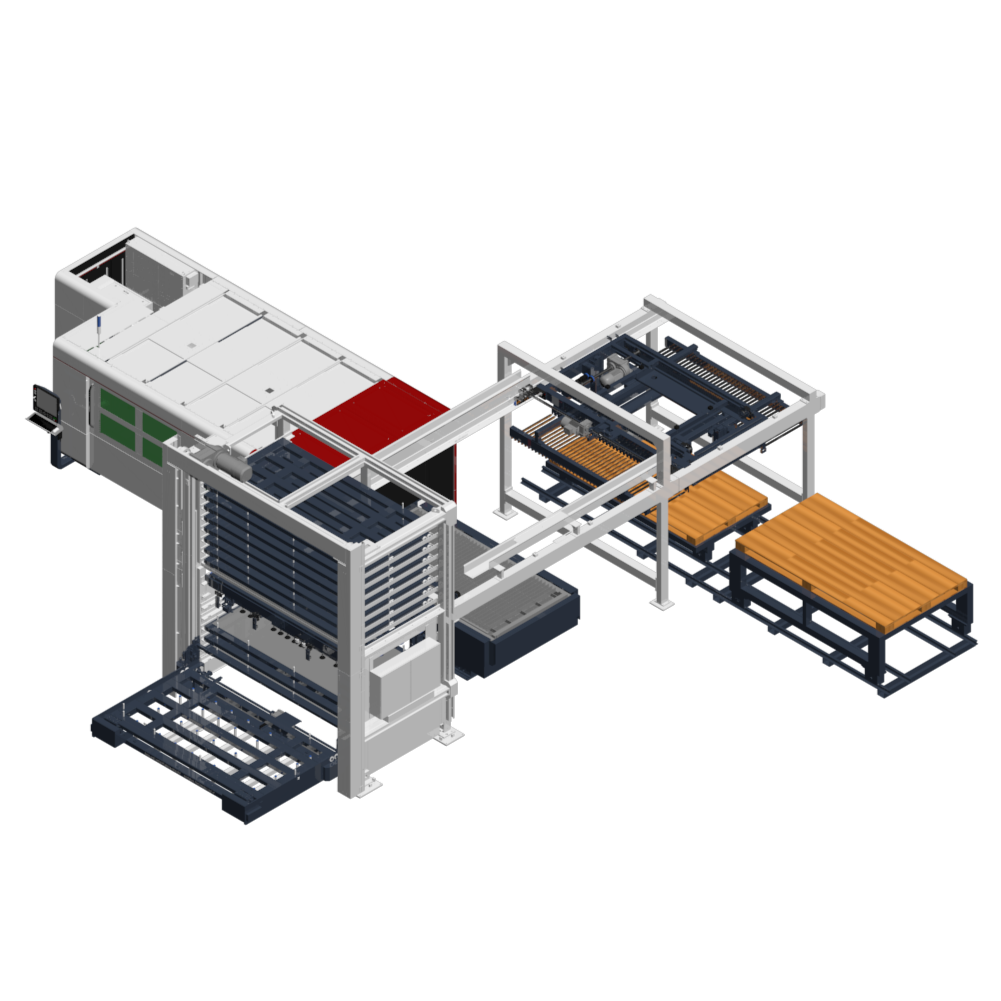

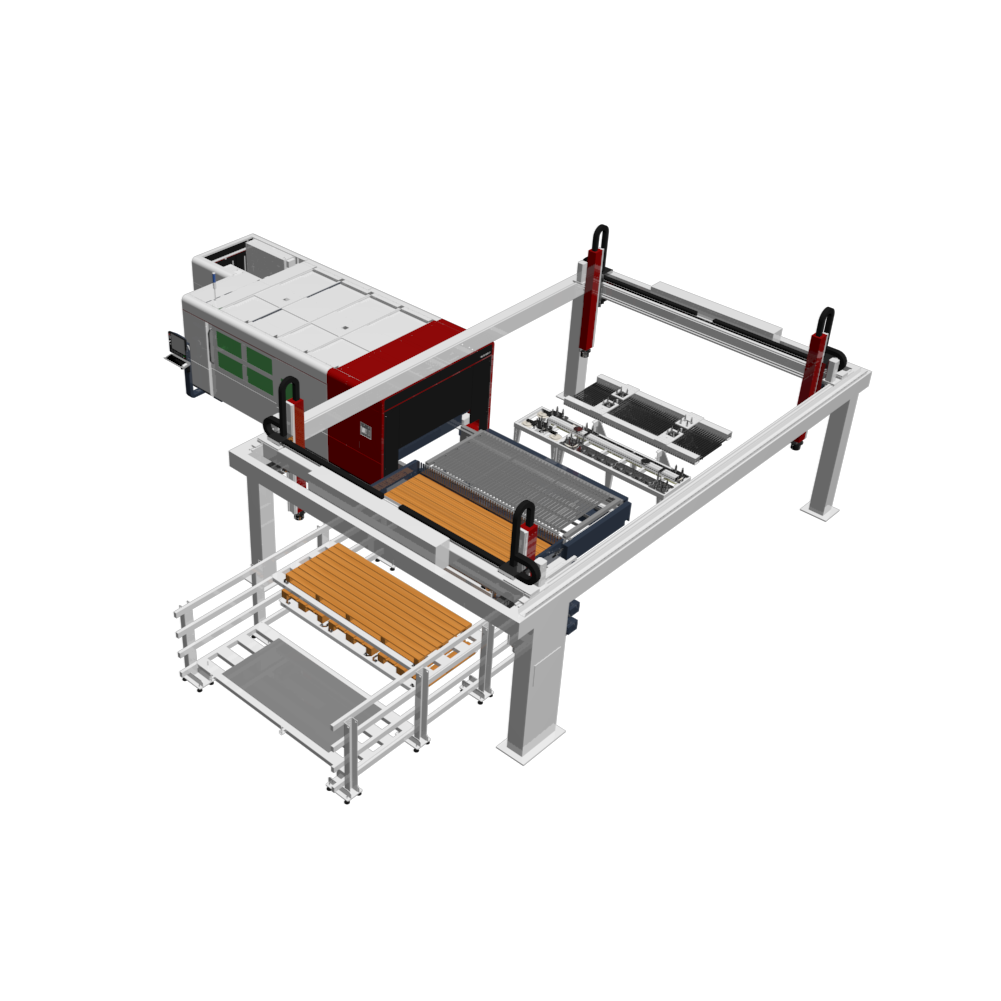

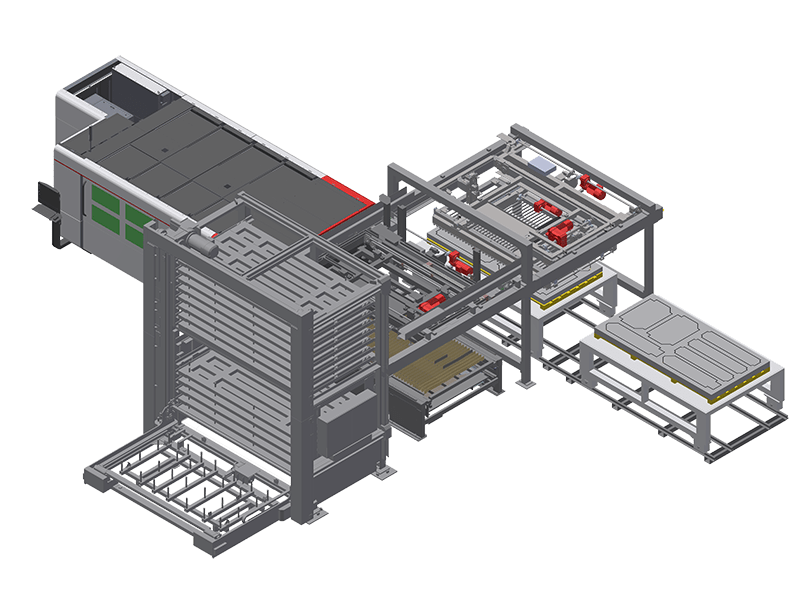

SmartFlex RAPID Base

This system is the core of our entire RAPID line; with the Base, you can Load from two high capacity carts with a total of 22,000lbs of raw material, and offload all that material to an identical set of offload carts. Productivity is kept at a maximum with the help of features like sheet separation, thickness detection, Aerial Positioning, and of course that industry leading 52 second cycle time.

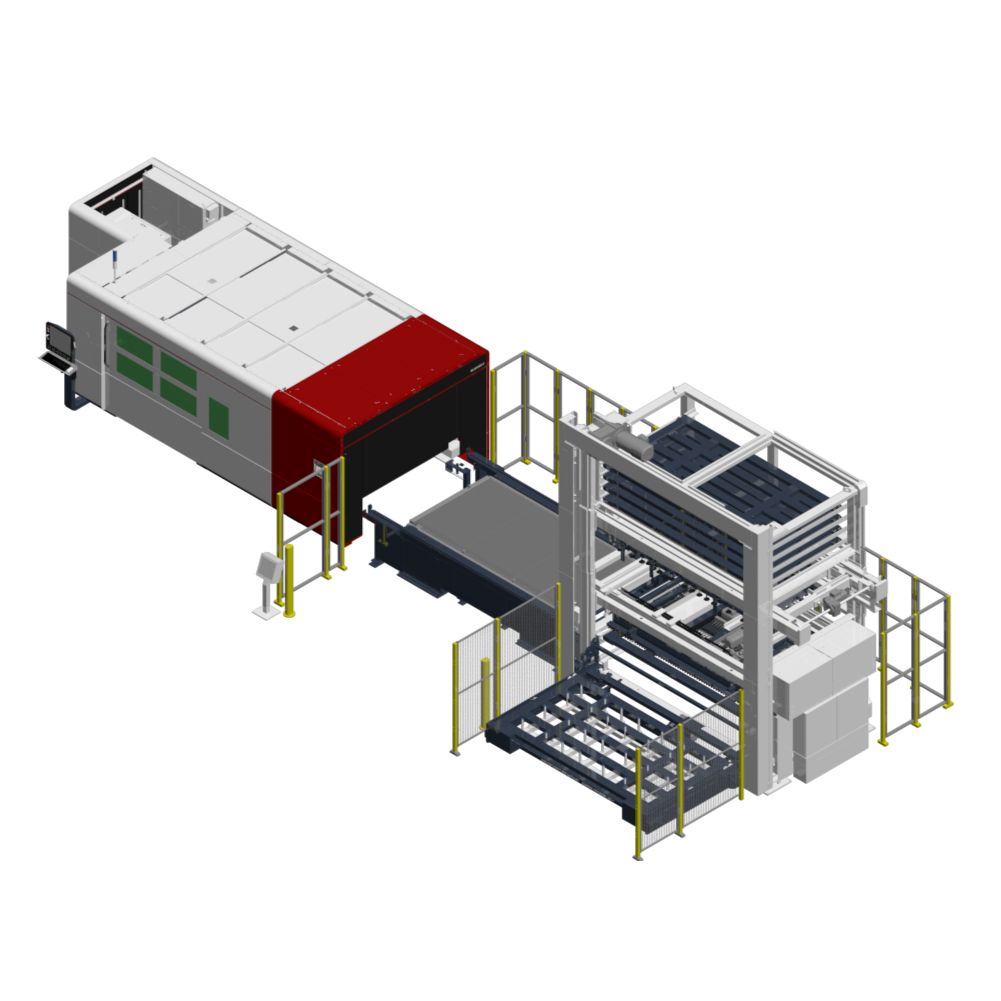

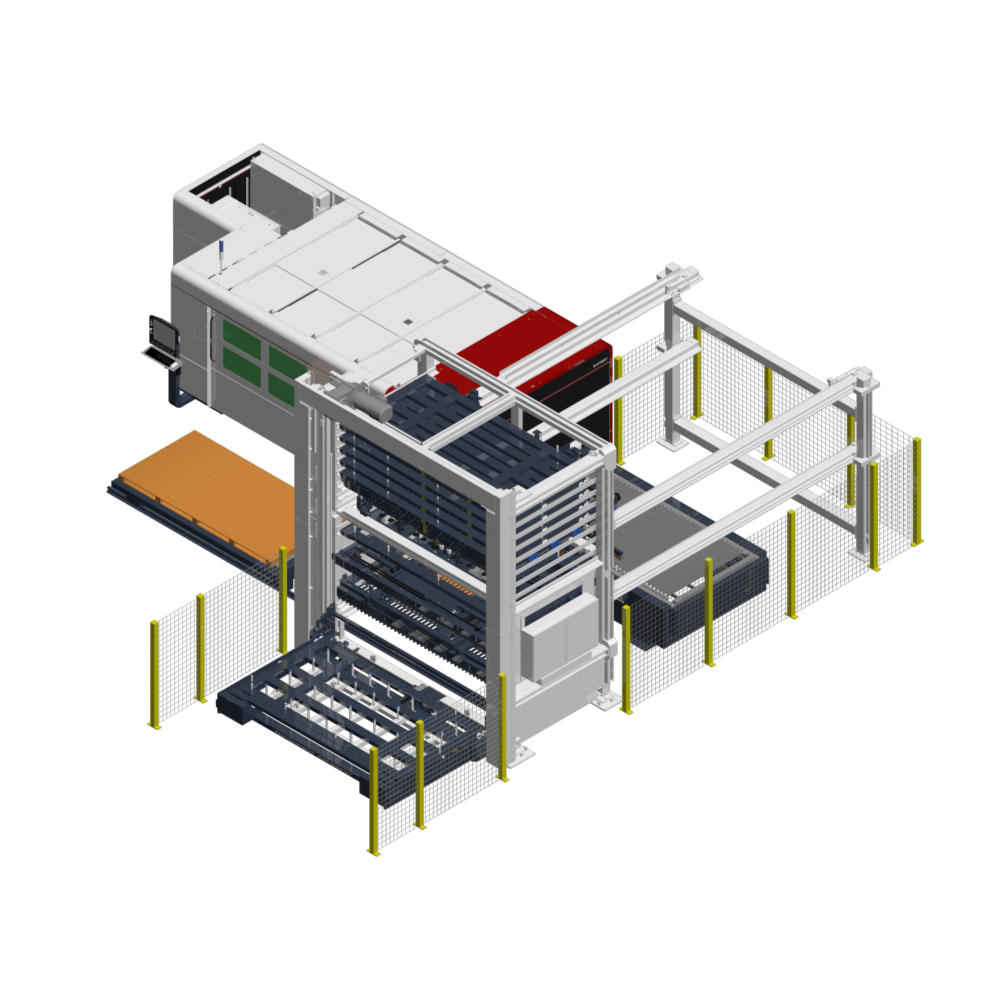

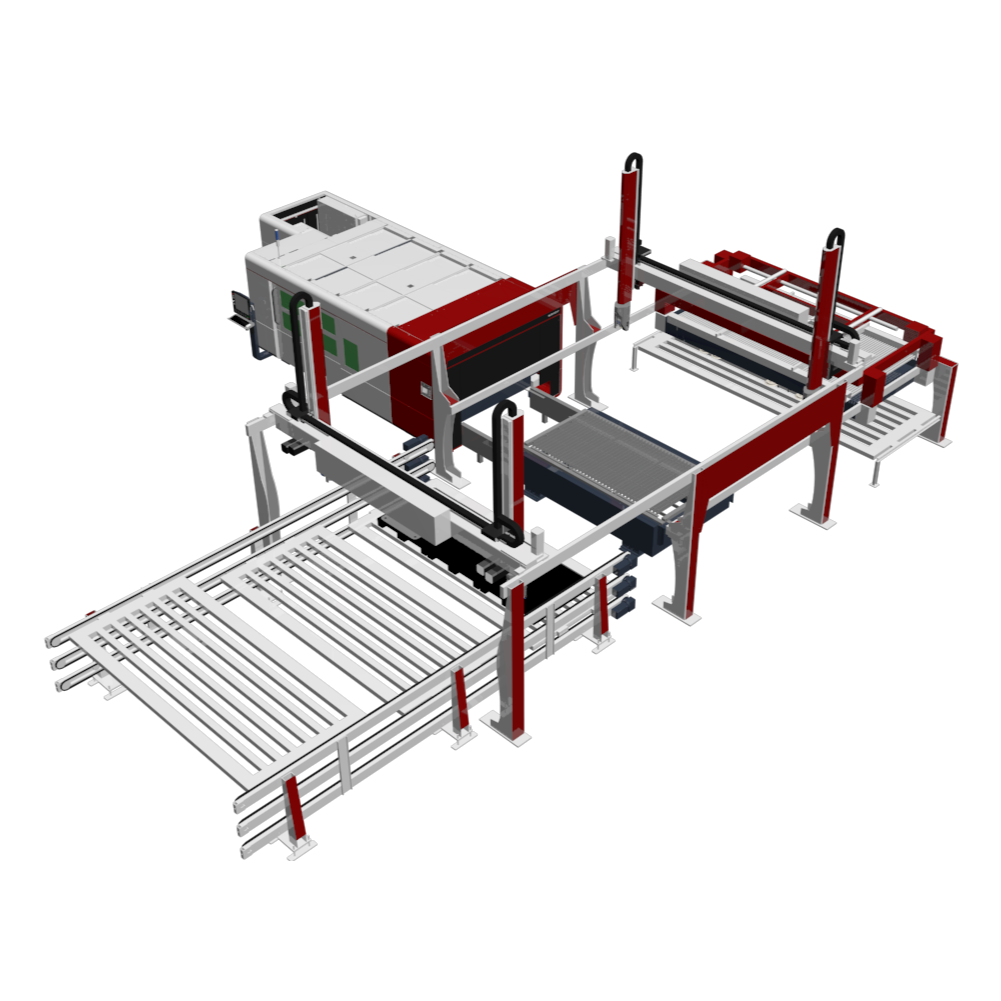

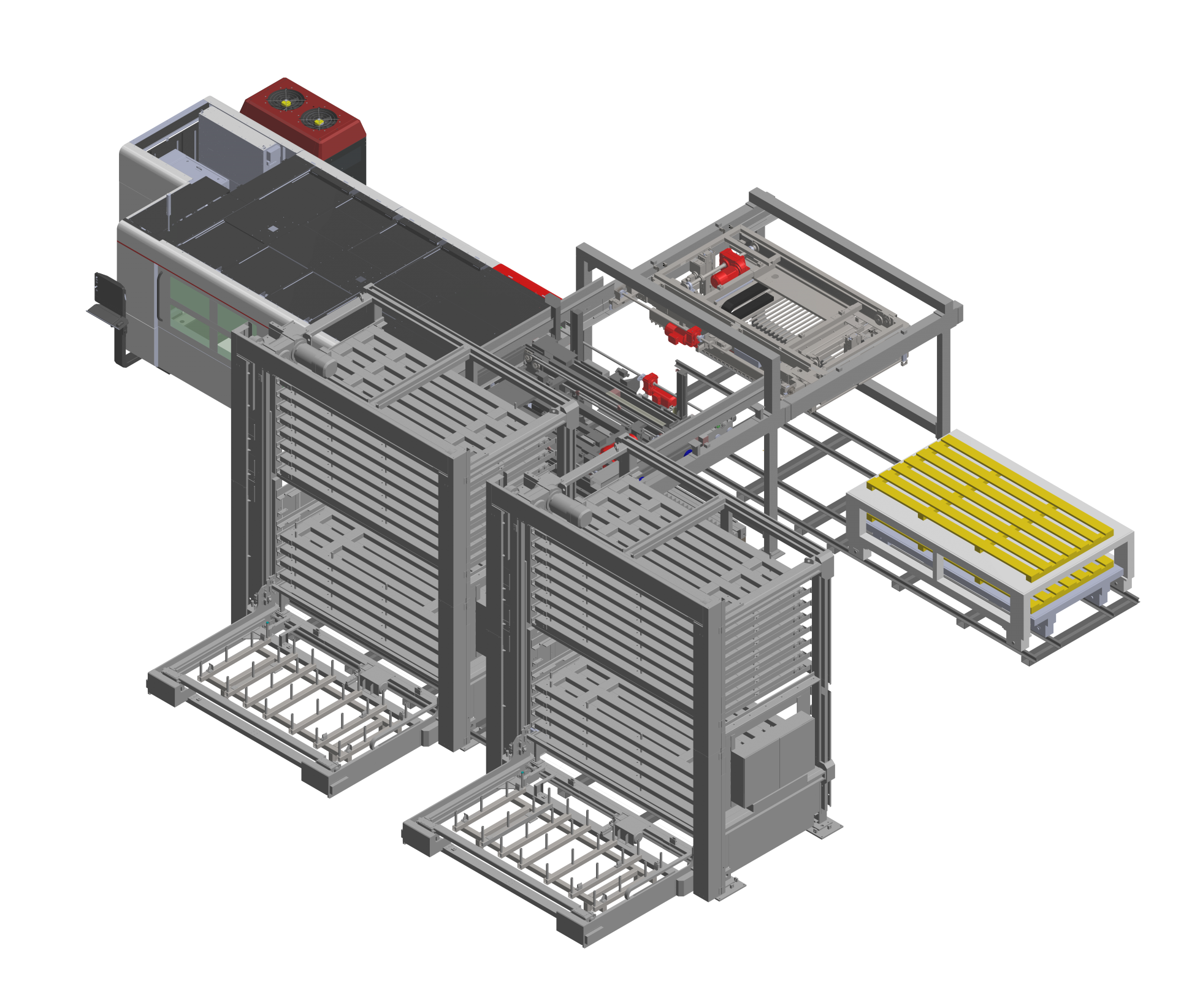

SmartFlex RAPID Tower

Our RAPID Tower maintains all of the advanced features and speed of our RAPID Base with the added ability to store an incredible amount of raw material with a standard 8 shelves. It can be configured with as many as 46 shelves with multiple towers and can be serviced by up to 3 lasers on a single line.

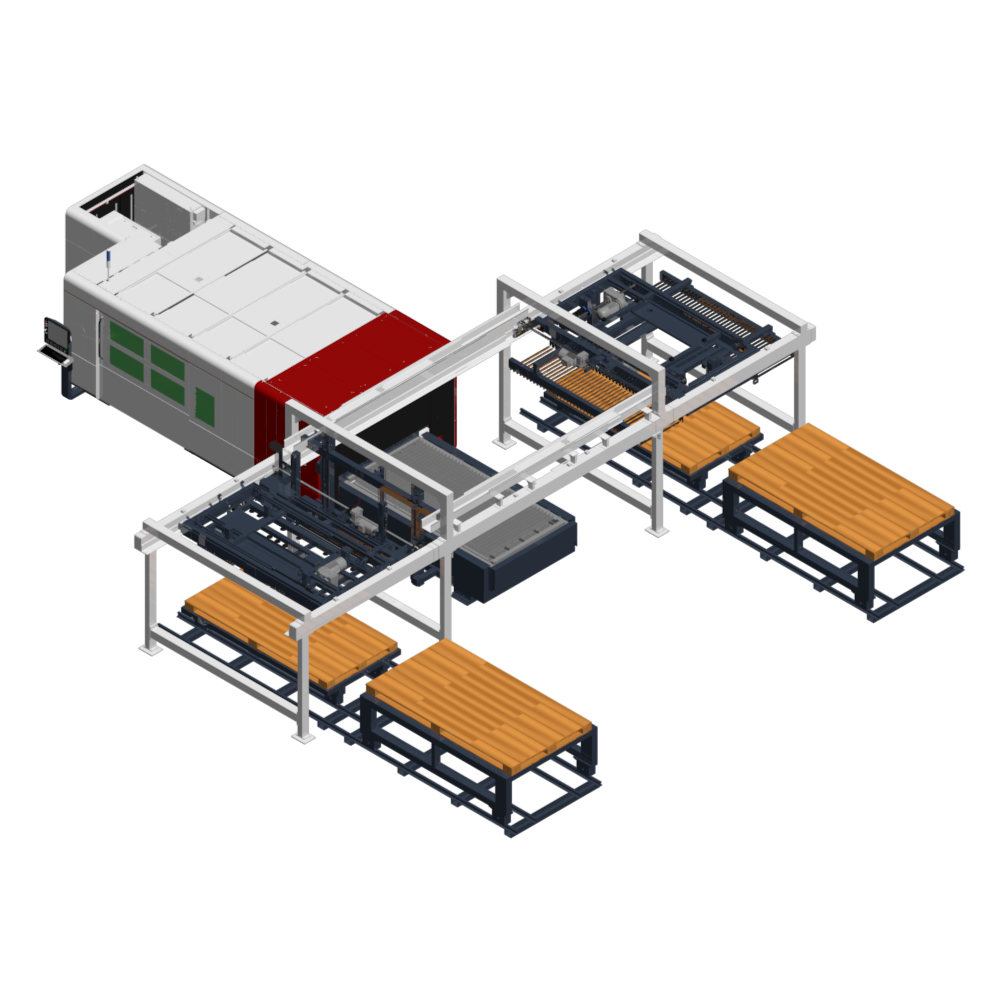

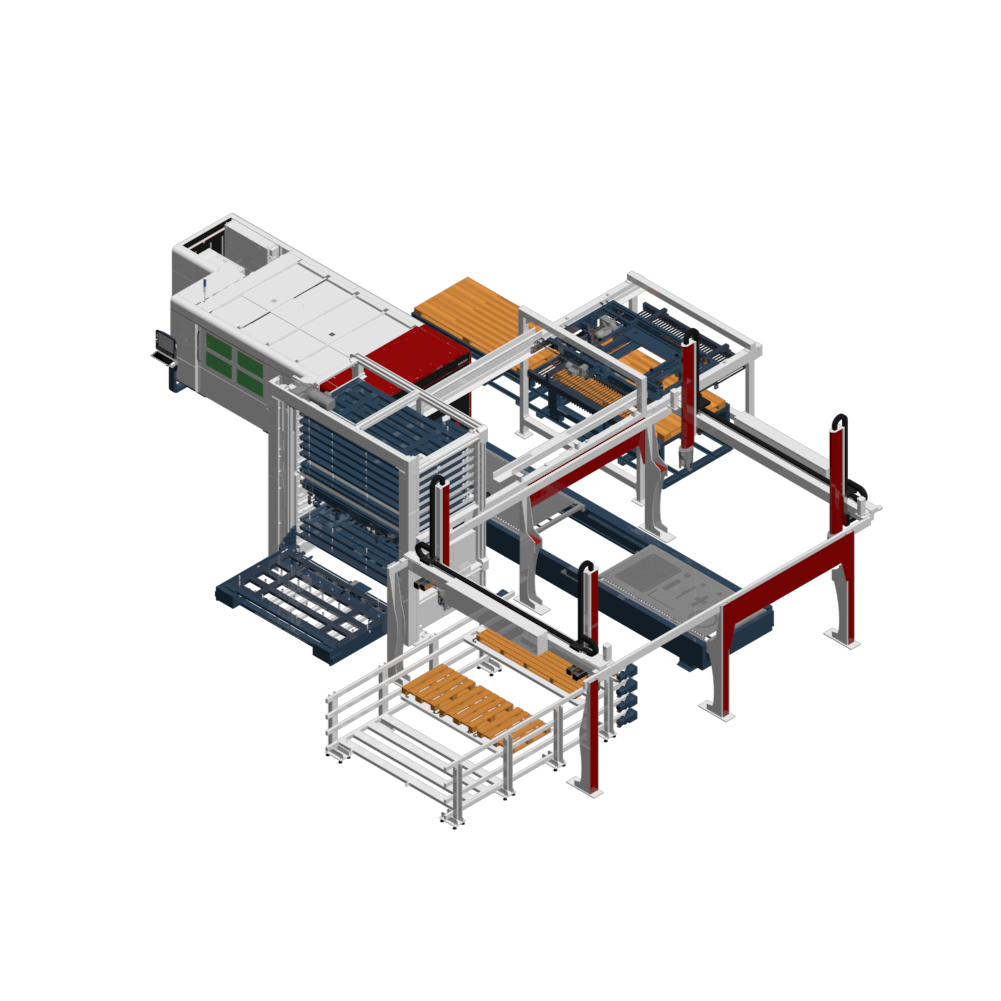

SmartFlex RAPID Double Tower

Our RAPID Double Tower maintains all of the advanced features and speed of our RAPID Base with the added ability to store an incredible amount of raw material with a standard 8 shelves. It can be configured with as many as 46 shelves with multiple towers and can be serviced by up to 3 lasers on a single line.

SMARTFLEX RAPID CAPABILITIES:

- Changes pallets in as little as 45 seconds

- Completely modular and expandable

- Simultaneous, high-speed loading and unloading

- Complete load/unload cycle in 52 seconds (3015) or 62 seconds (4020)

- 5×10 machine can load/unload sheet sizes of 4×4, 4×8, 4×10, and 5×10

COMPONENTS:

- Heavy-duty work support structure

- Optional integrated work-lifter system

- NC-based pallet changer status screen

- Vacuum-load system with thickness detection and sheet separator features

- Heavy-duty clamshell fork unload system with built-in sheet-raking system

- Aerial sheet positioning for high accuracy and positive sheet locating to the cutting table

SYSTEM INFORMATION:

- Fully compatible with DiamondFAB laser automation software

ADDITIONAL BENEFITS:

- remote360°-enabled (remote user monitoring, diagnostics, service support, and more)

TOWER FEATURES:

- Second load station allows simultaneous material preparation

- Heavy-duty, full-size sheet load/unload capacity (up to 1”)

- Capacity of 3 metric tons (6,000 lbs.) per shelf

- Up to 46 shelves (multiple towers) for a total of over 303,600 lbs. of capacity

| SYSTEM SPECIFICATIONS | ||

| MODEL | 3015 | 4020 |

| Cycle Time: Seconds | 52 | 62 |

| Load Weight (Tower): lbs. /shelf | 6,600 | 6,600 |

| Unload Weight (2 Carts): lbs./cart | 11,000 | 11,000 |

| System Footprint (Tower): L x W ft. | 43’ x 52’ | 51’ x 63’ |

| Shelf Count: Min to Max* | 8 to 46 with double tower option | 8 to 32 with double tower option |

SmartFlex RAPID Laser Automation

RELATED SOLUTIONS

-

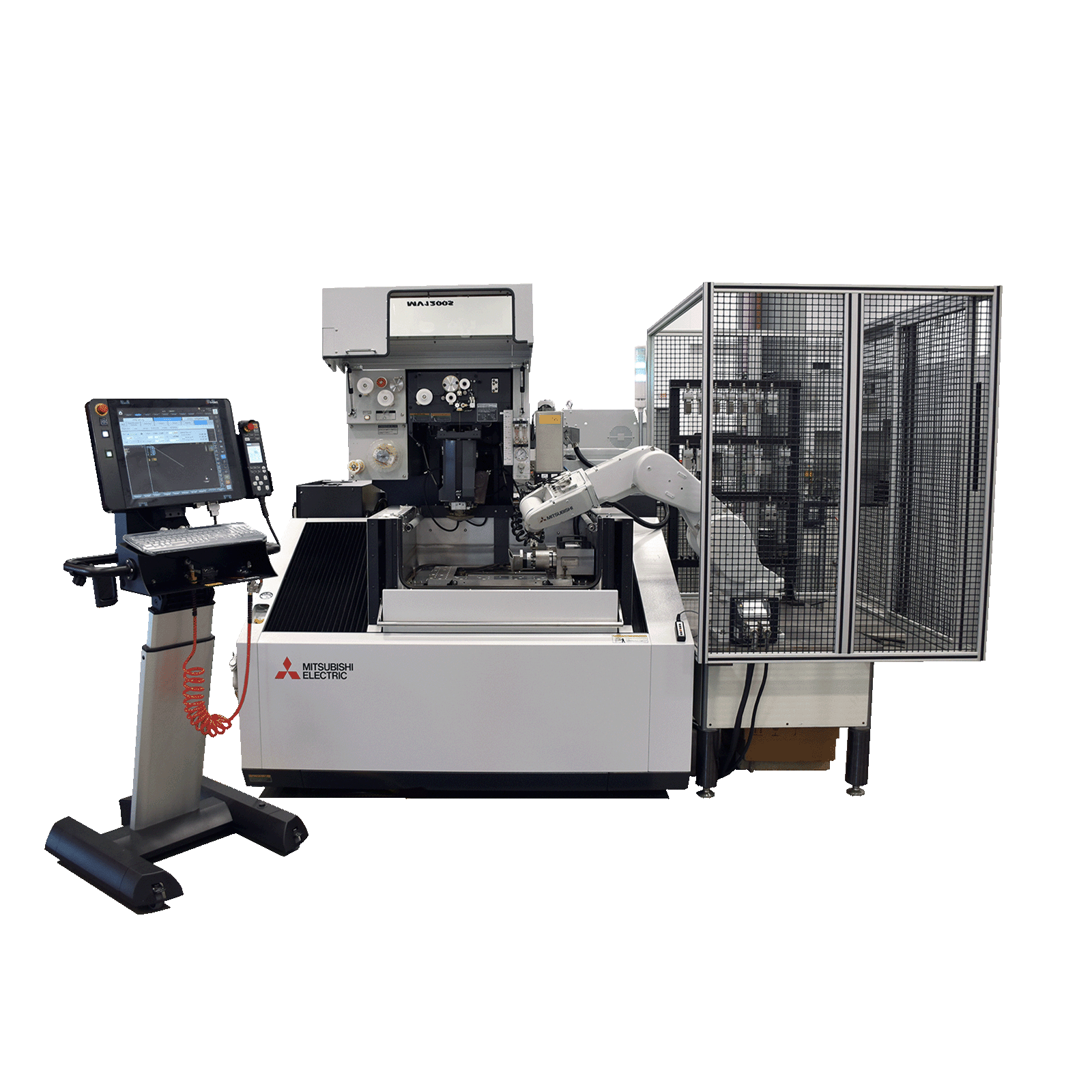

EDM AUTOMATION

The ultimate solution to improve throughput, increase production, reduce manpower, and be more competitive.

learn more -

LASER AUTOMATION

Leave your bottom line beaming.

learn more -

PRESS BRAKE AUTOMATION

Stretch your throughput capacity to new levels.

learn more -

MILLING AUTOMATION

Increase throughput and maximize your resources.

learn more

-

"Ever since we’ve had the (SmartFlex Element Type R) automation tower, it has been an absolute game changer. I think that if you don’t have an automation system on your laser, you are wasting so much opportunity, especially if you’re looking to add additional work to your machine."

Blake Hamar, President of Cali Raised LED Read customer success story -

"Thanks to our advanced manufacturing techniques, we are able to keep up with demand and keep products in stock where our competition can't."

Blake Hamar, President of Cali Raised LED Read customer success story