INTRODUCING THE

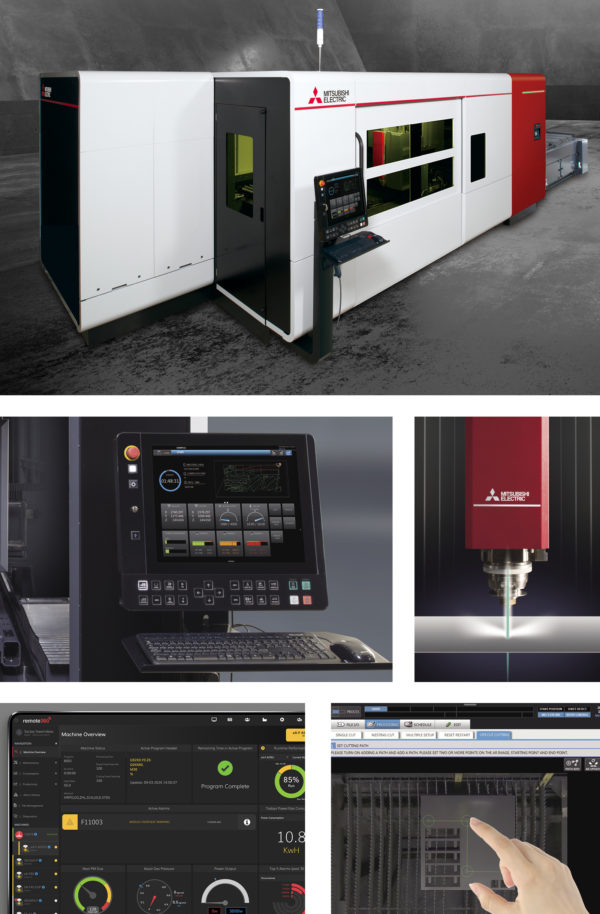

GX-F ADVANCED SERIES

GX-F ADVANCED SERIES

Less Input. More Output.

Power lies in what a fiber laser can do, not the kilowatts it has. With the manufacturing industry suffering from a shortage of experienced workers, Mitsubishi designed this new generation of fiber lasers to minimize the need for operator input while maximizing quality and productivity.

Lower operating costs mean higher profit margins.

With the latest in artificial intelligence (AI) and gas reduction technology, the new GX-F ADVANCED Series of two-dimensional fiber lasers delivers more power while using up to 77% less nitrogen.

Advanced zoom head adds more vroom.

The Mitsubishi proprietary optical system provides speed and flexibility, allowing the zoom head to automatically change beam size, shape, and focal point according to the material plate thickness.

AI-Assist makes it smart.

Using audio and light sensors to monitor the cutting process in real-time, it automatically adjusts parameters to optimize cutting performance for a true nonstop processing experience.

Eliminate the guesswork.

Its augmented reality (AR) technology displays overhead 3D images of the system without distortion, allowing you to easily place and nest parts to reduce setup time.

Avert downtime with remote360™ machine monitoring.

The GX-F ADVANCED Series comes with two years of remote360 production monitoring and support, which provides real-time data to help increase productivity, improve efficiency and reduce downtime.

And because the GX-F ADVANCED Series is built with Mitsubishi components, it’s one of the only laser systems in the industry with a single source for service and support.