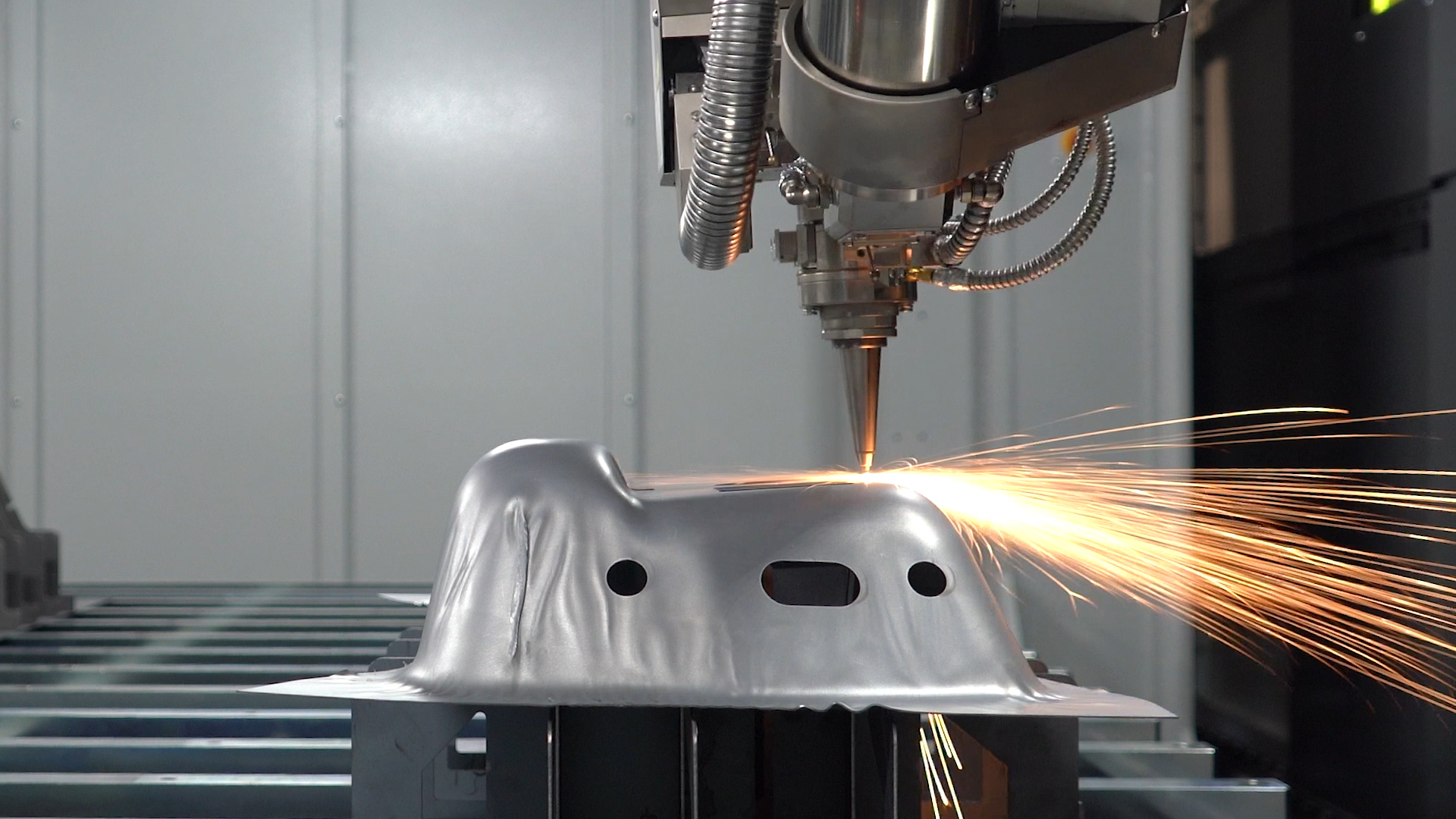

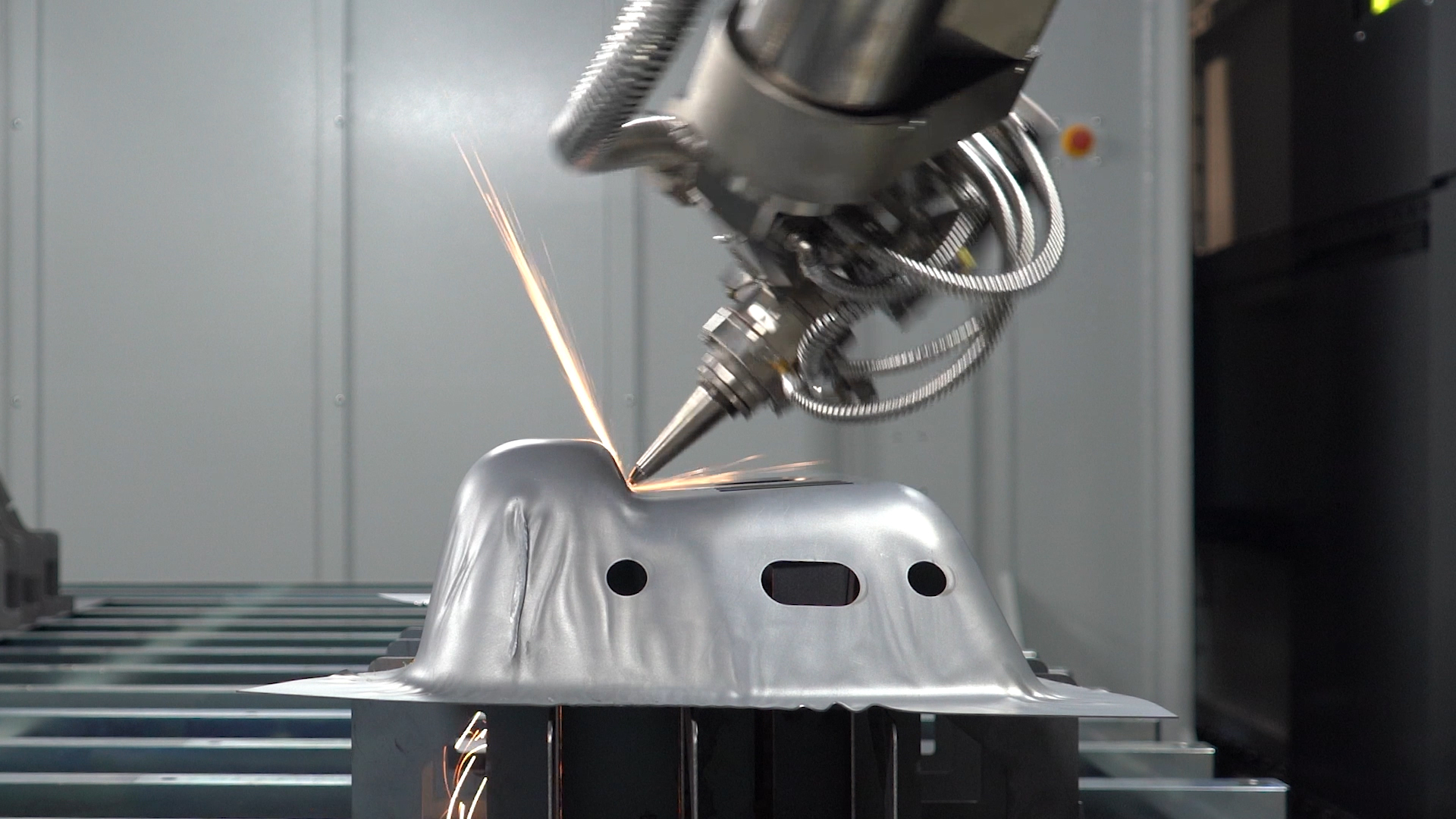

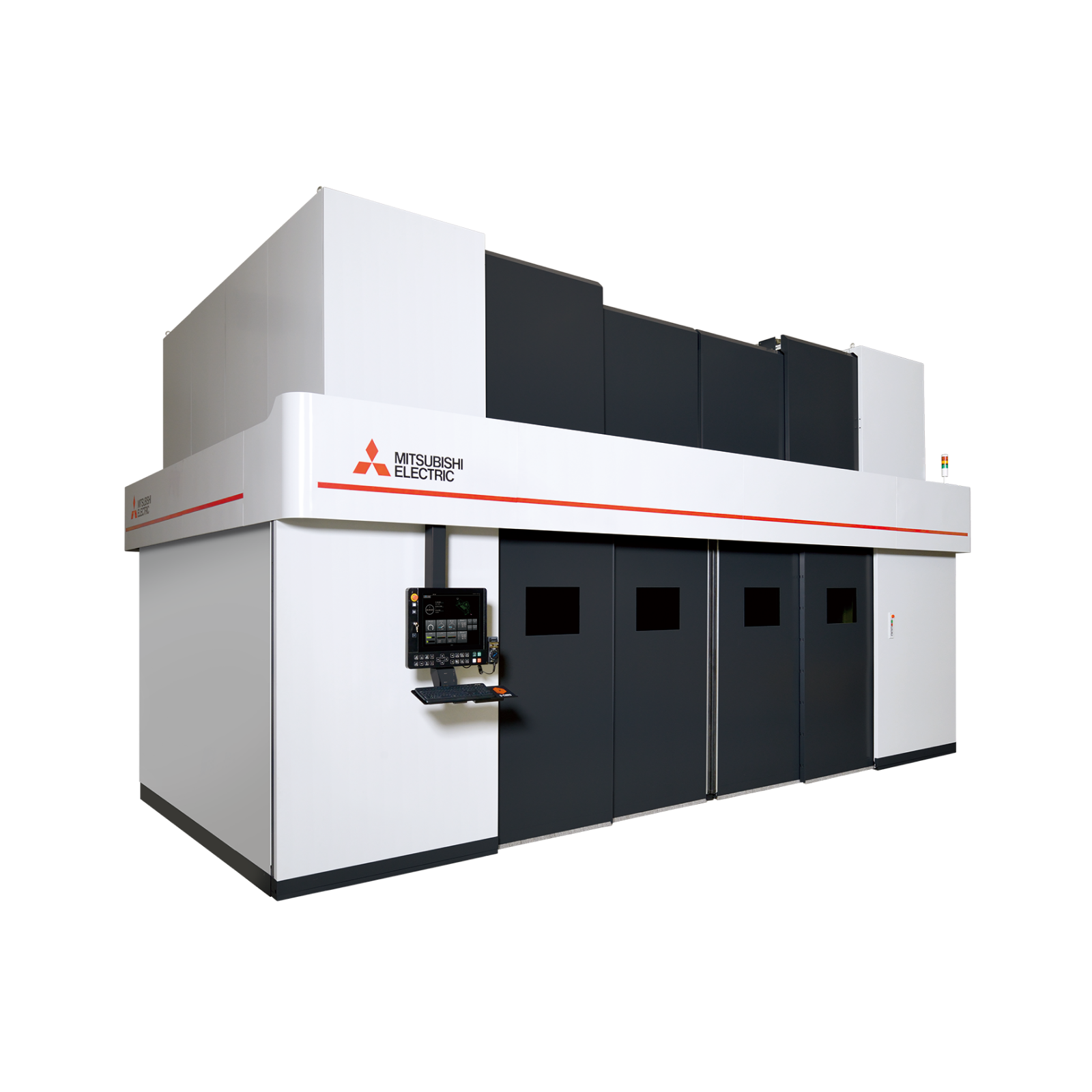

The new Mitsubishi FV five-axis fiber laser features the fastest processing in Mitsubishi Electric’s history.

Along with a fiber optic laser, the FV uses an innovative double-rail gantry motion system for high-speed, accurate cutting and 4.0G H-axis acceleration for high-speed height sensing—a combination that delivers the fastest processing in Mitsubishi Electric’s history.

The FV’s major components are all made by Mitsubishi, including the oscillator and new platform X frame, meaning Mitsubishi Laser is the single source for service and support.

Other features include:

-

- An open architecture fixture table, allowing for easy access to cut parts and loading/unloading of material.

- Magnetic crash protection, which provides faster recovery time, prevents the need for mechanical or optical alignment and reduces the risk of drive system damage.

- The advanced M800 control system, which improves processing speed and accuracy. New control features include a customizable home page, expanded cutting condition library and robust maintenance screens.

- The Mitsubishi Laser oscillator, which offers maximum processing capability with back reflection beam isolation and beam mode stabilization technology.

This high-performance laser cutting system combines Mitsubishi’s latest developments in machine, CNC control and automated material handling system technologies.