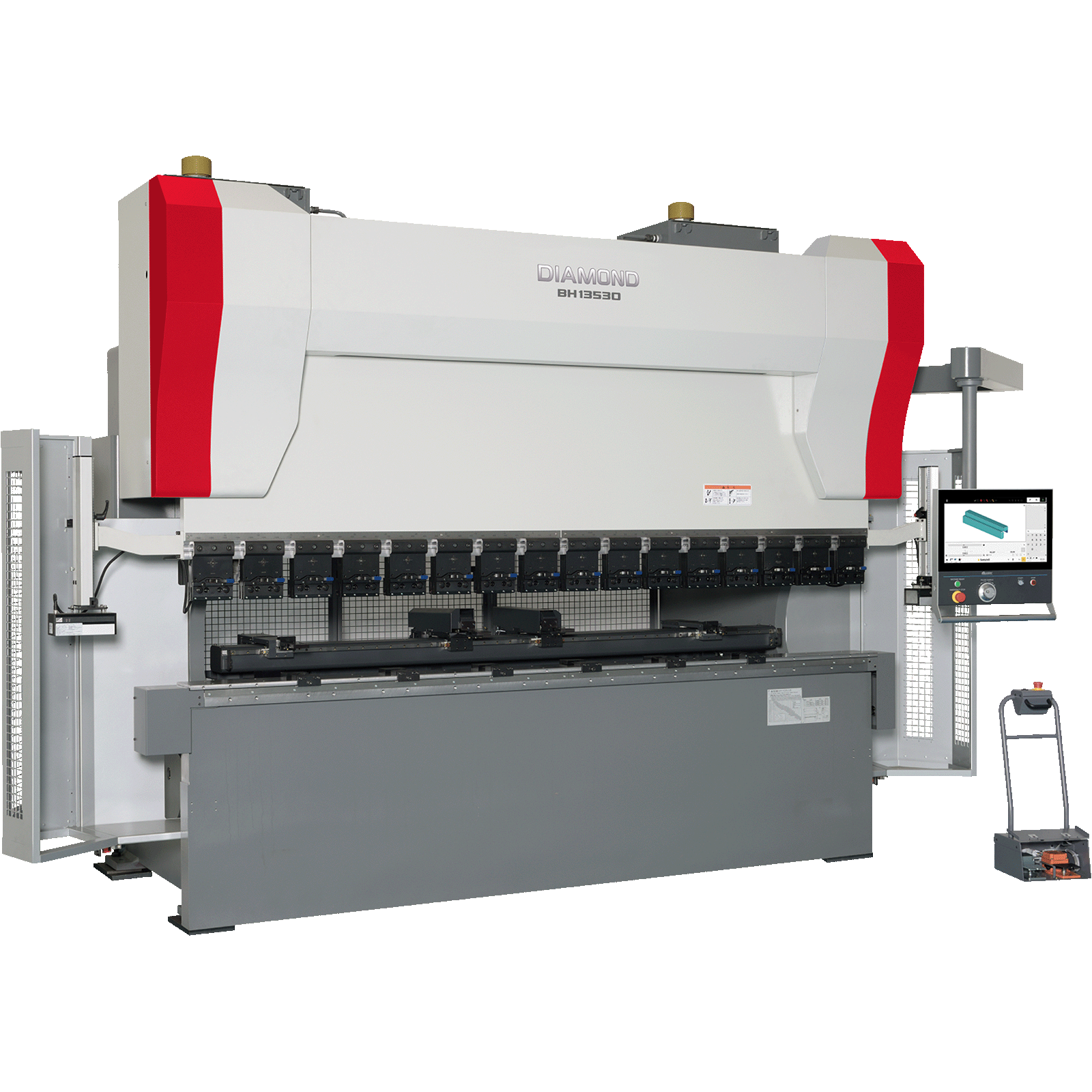

PA Basic Series

Flexible and reliable bending performance with patented HEXA-C® frame – all in a cost-efficient package.

The PA Basic series brings quality at an attractive price-performance ratio providing manufacturers the highest standards for precise bending in a hydraulic press brake; you can count on the PA to do the job well.

But we know that producing quality work is only part of the equation. You have a business to run, and finding the right balance between performance and profitability is too important to overlook. That’s where the PA Basic series hydraulic press brakes do their best work.

Sporting an intuitive user interface that allows you to take full advantage of this machine’s heavy-duty bending capabilities, the PA Basic series is the affordable, high-performance press brake option you can feel good and confident about adding to your floor.