Robotically Integrated Bending Solutions (RIBS)

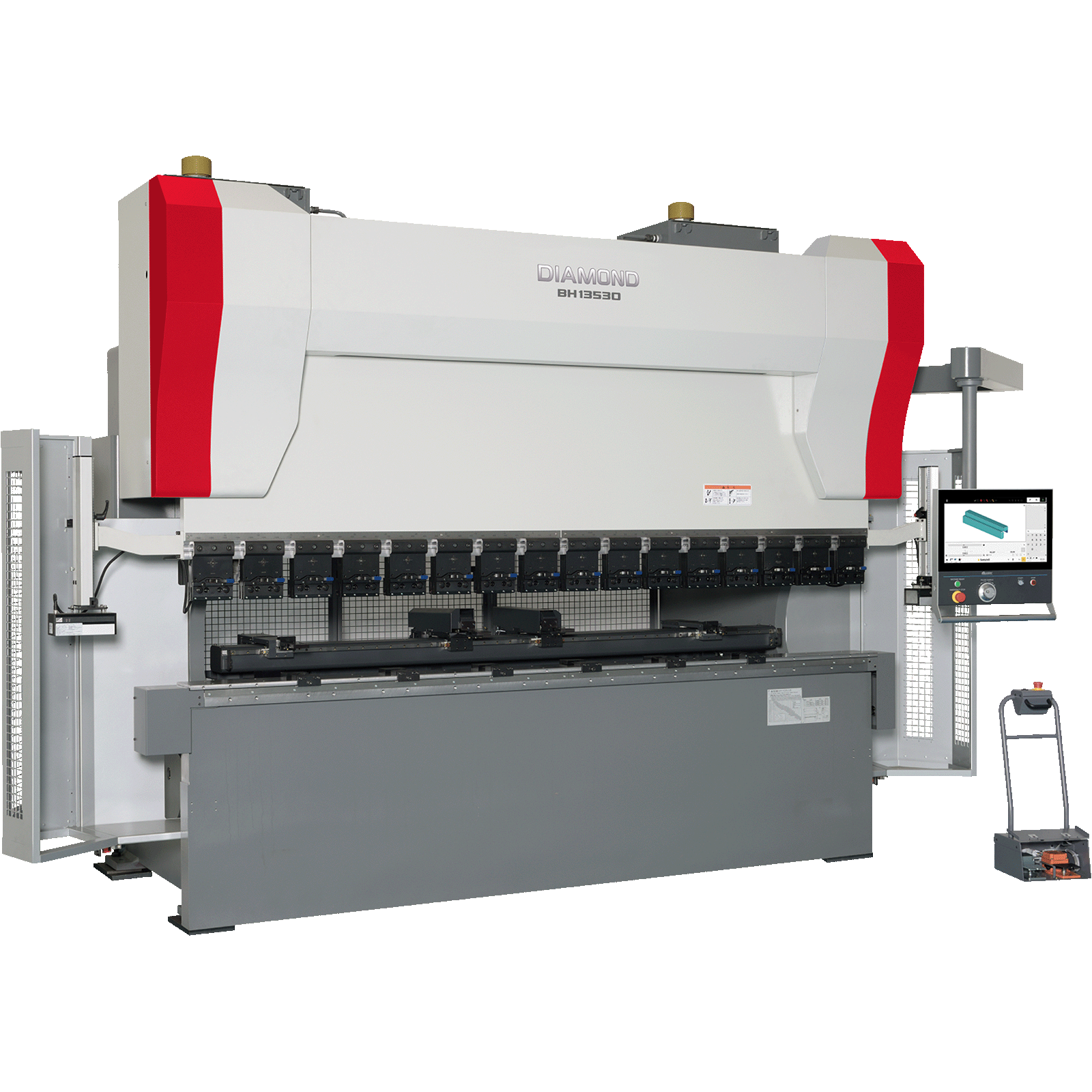

Featuring the Acieta RIBS robotic solution and our Mitsubishi Diamond BB Series of electric press brakes, this advanced bending system eliminates manual bottlenecks while increasing productivity, consistency, and safety. The RIBS cell is ideal for small to large parts and mid- to high-volume production environments ready to automate bending with precision and repeatability.

Benefits

• Increased throughput and uptime

• Improved part quality and accuracy

• Reduced operator fatigue and injury risk

• Consistent performance across shifts

• Scalable automation for future growth