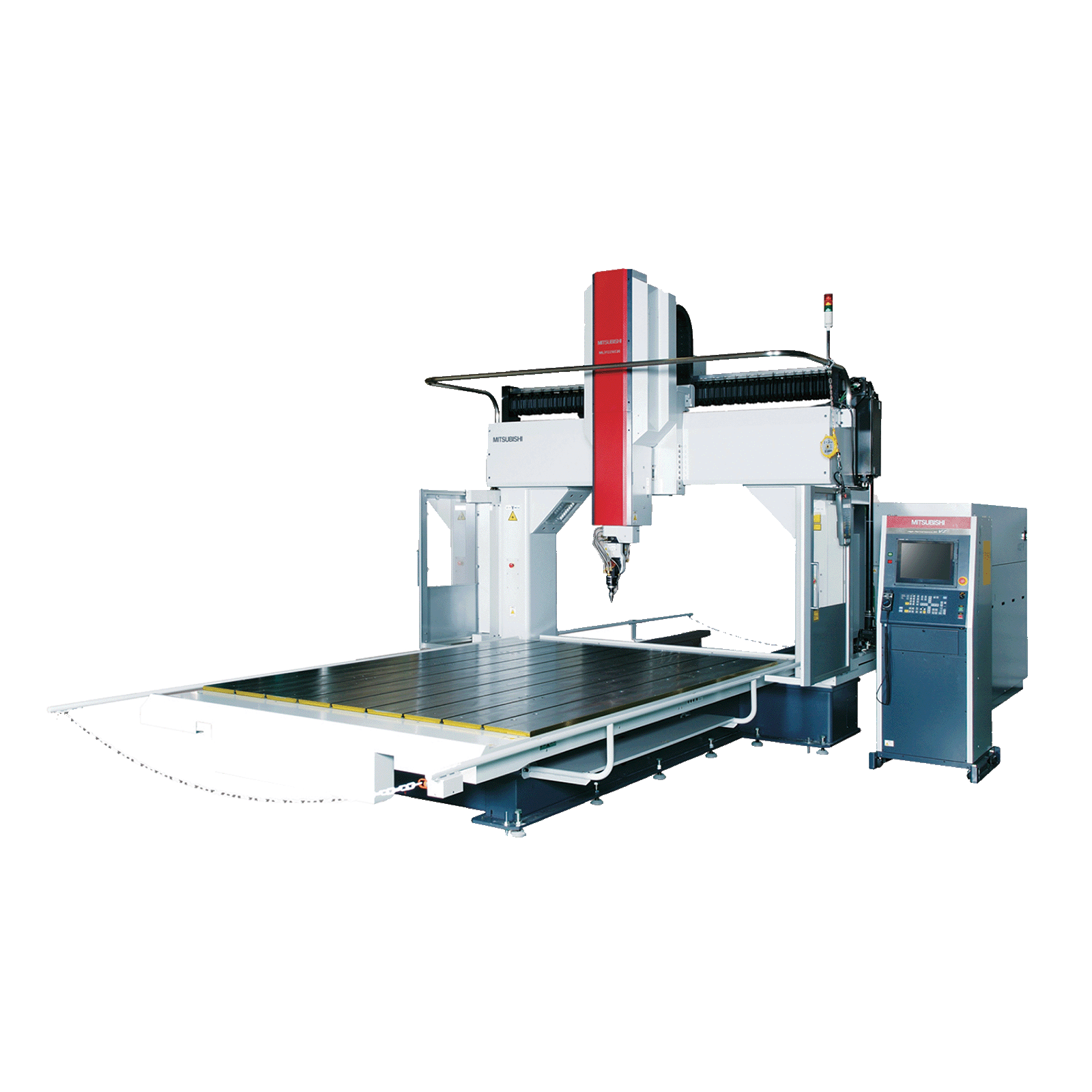

VZ20 3D Laser

Delivering unparalleled utility, flexibility, and working speeds along with ease of operation and low operational cost.

Mitsubishi’s VZ series, comprised of 3D laser cutting systems, offers the accuracy and flexibility needed for a wide range of users.

The VZ20 significantly decreases the time required to produce complex parts while still providing the greatest degree of accuracy. And, thanks to its expanded teaching functions, creating top-quality work at maximum speed is always an option for any user—regardless of skill. For an unprecedented level of control over the most important parts of your business—from product quality to cost-efficient resource management—the VZ20 brings it all together.

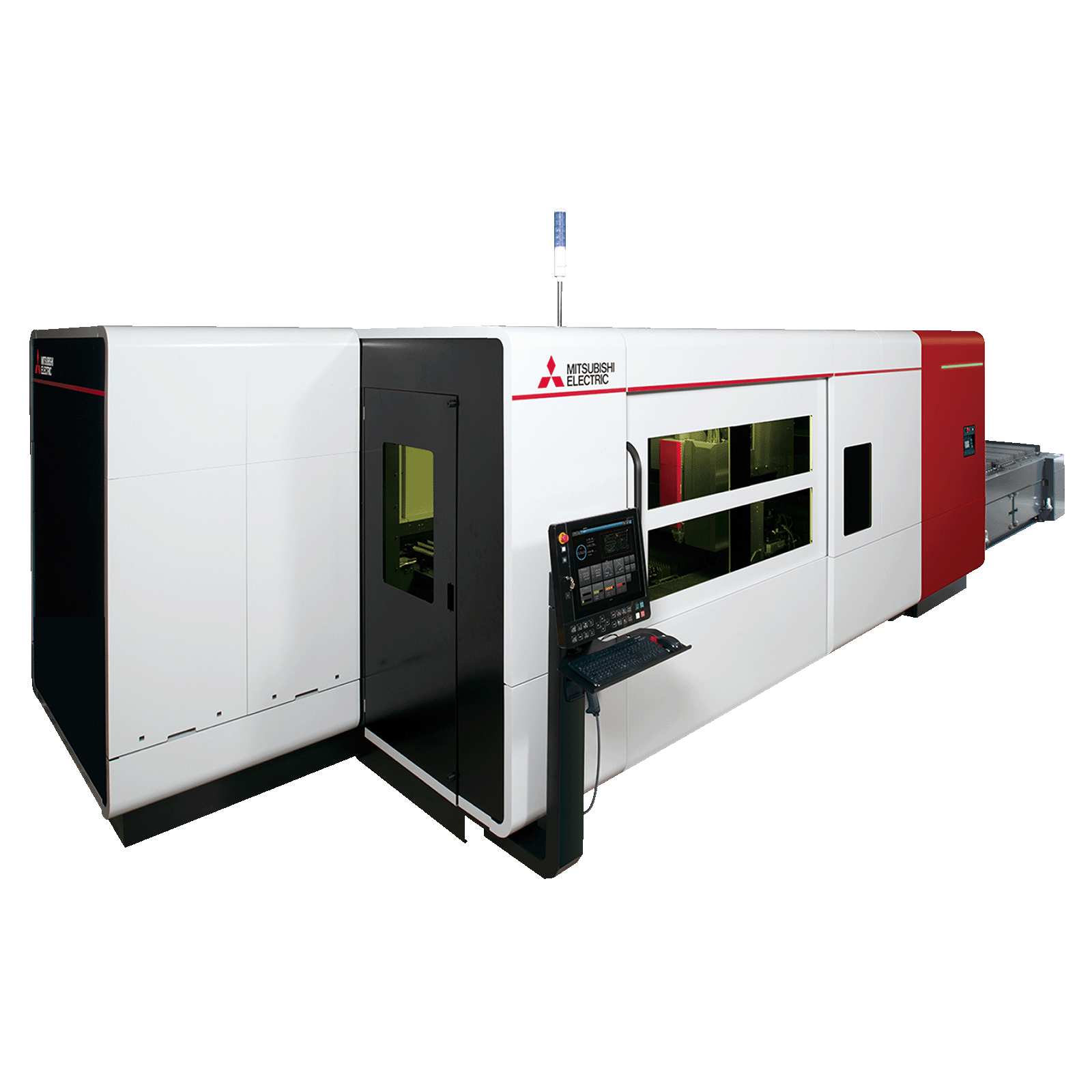

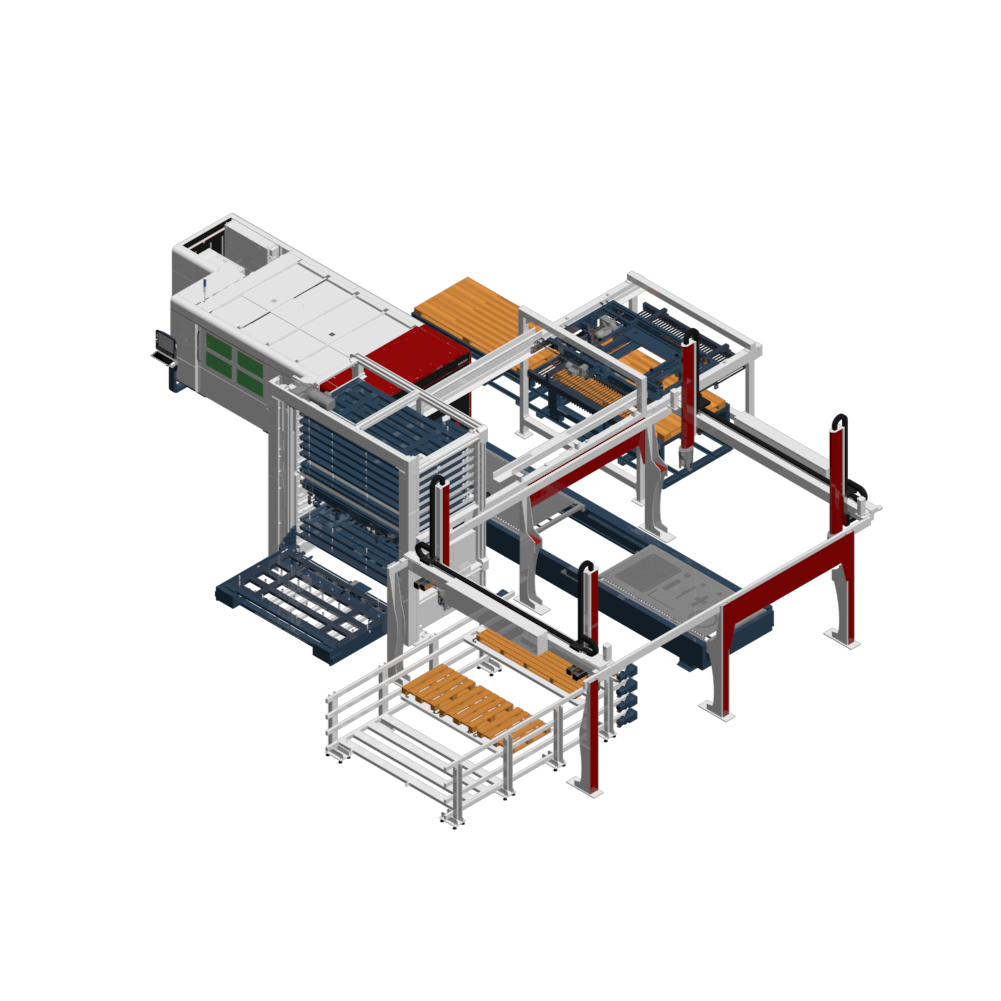

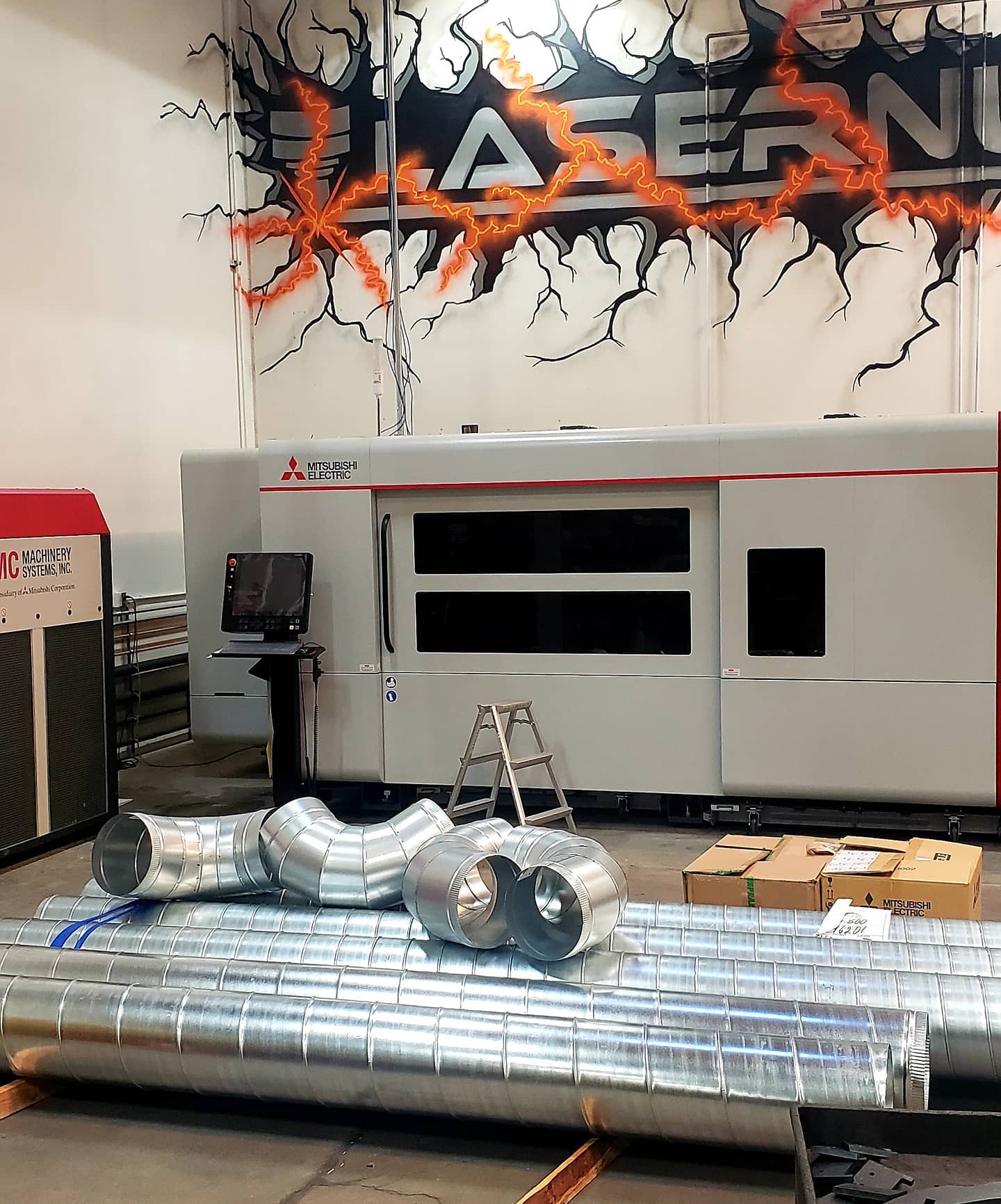

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.