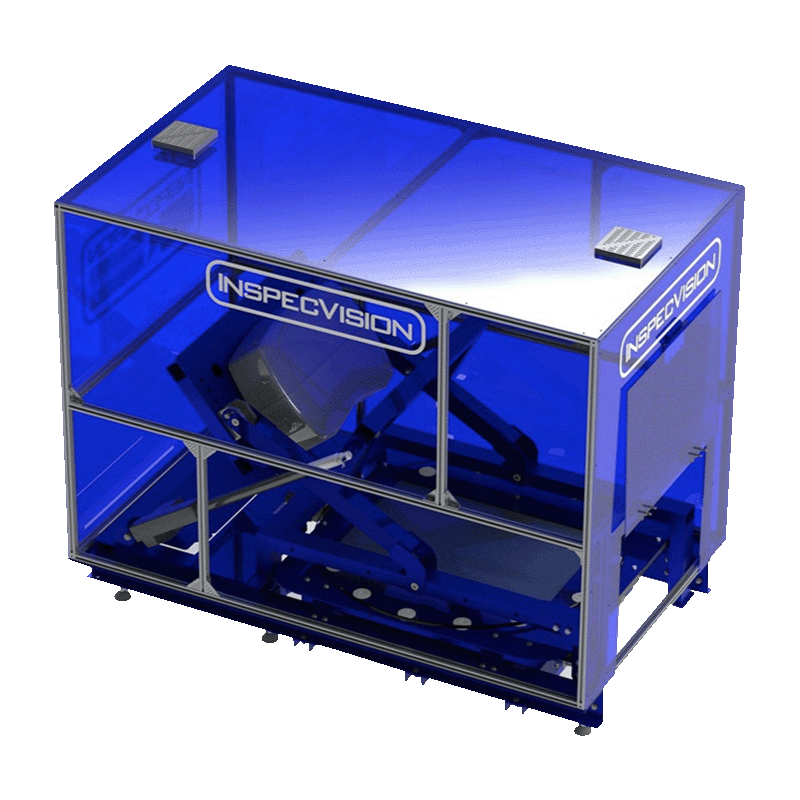

InspecVision Opti-Scan 3D

Bridging the gap between man and machine with intuitive, high-powered 3D inspection capabilities.

CENIT offline programming solutions cover the entire CAD/CAM and simulation components for 3D laser applications, offering improved flexibility and functionality through a robust yet accessible platform.

Other benefits include improved data handling for shorter programming times, no data conversions due to V5 integration, and advanced functionalities for sophisticated contours.

MAKES HIGH-ACCURACY SCANS EASIER TO USE

A back-light table can be used to capture the silhouette of the part. This silhouette image is then converted into 3D edge measurements using our patented Planar Edge 3DTM technology.

3D edges are essential when measuring sheet metal parts as the critical features, such as hole size and position, are defined by the part’s edges, not its surfaces. Competing 3D scanners can acquire measurements of surfaces but are notoriously bad at acquiring measurements of edges.

The Opti-Scan is the only system in the world that can accurately measure surfaces and edges in 3D.

OPERATION IS QUICK, SIMPLE, AND EFFECTIVE

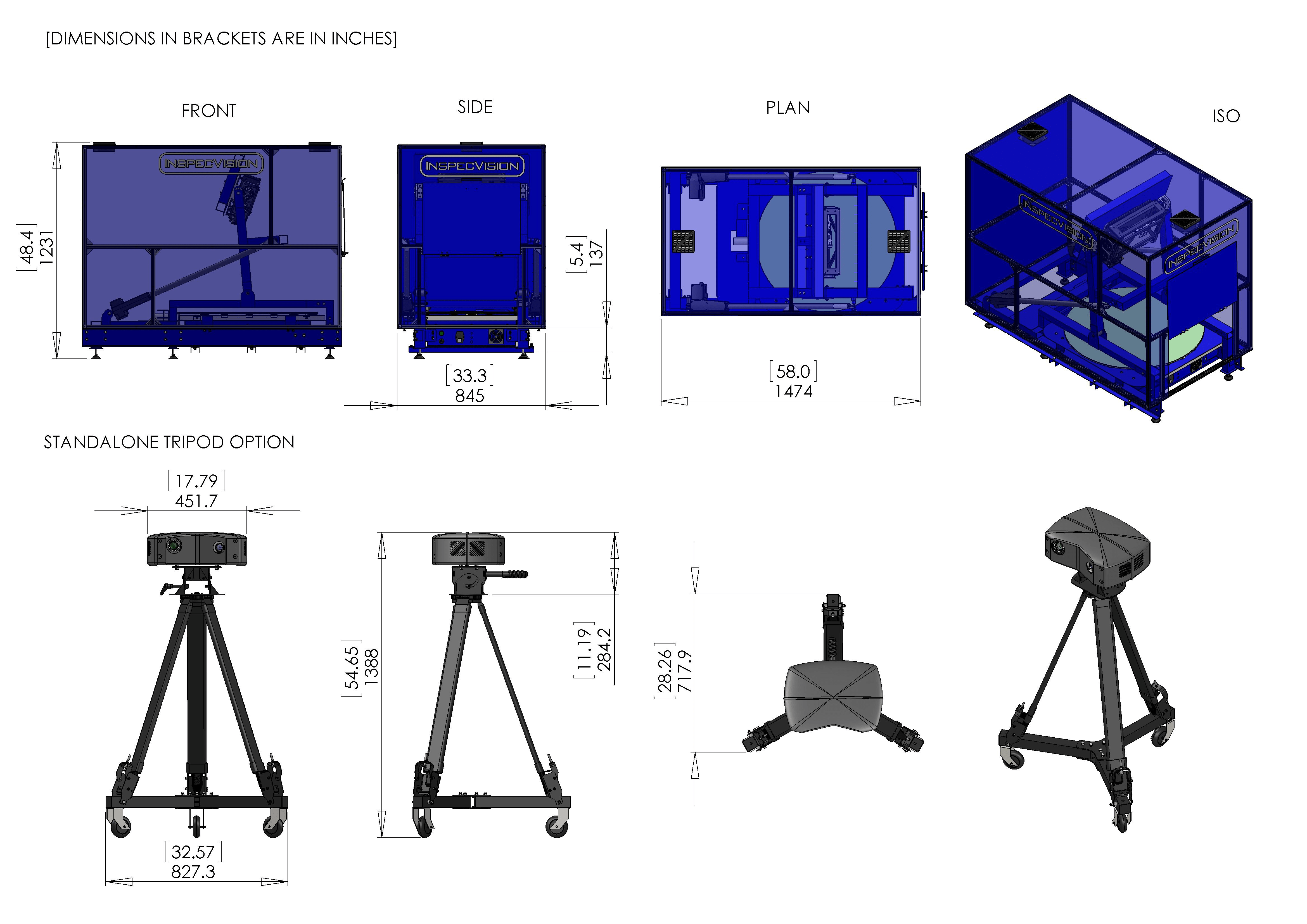

InspecVision achieves high levels of automation by adding a rotational table and tilting mechanism. This arrangement has been carefully chosen to create a viewing hemisphere that allows scans to be acquired from all visible surfaces of the component.

The rotational table has a ring of reference markers which locate the table relative to the scanner. This removes the need for high-precision, expensive, delicate, moving parts which would need to be recalibrated and maintained.

The result is an unprecedented level of accuracy and automation. The system can inspect most 3D parts by simply placing the part on the table and scanning a bar code, or clicking a button.

UNCOMPROMISING QUALITY MEETS FLEXIBLE UTILITY

The Opti-Scan can also be used as a portable 3D scanner by placing the scanning head on a tripod.

Large objects can be measured by attaching repositioning markers to the surface of the part or to a measuring bench or area. These markers are then used to automatically stitch the scans together. In this configuration, almost any size object can be measured.

The system is also available as a retrofit to our Planar 2D machines. Furthermore, our Opti-Probe device can be used by the Opti-Scan to probe hidden features.

All of our Opti-Scan systems use at least 18MP cameras; this resolution is several times larger than the nearest competing product, which typically use 5MP or even 1MP cameras. All Opti-Scan 3D units capture object texture and geometry; color cameras are available on request.

| Model | OS1000.35 | OS1000.35LA | OS1000.35LM | OS350.10 | OS350.10LEA | OS350.10LEAA | OS350.10LEM | OS800.35 | OS800.35.LA | OS800.35LM |

|---|---|---|---|---|---|---|---|---|---|---|

| FOV (1) Field of View, mm | 1,000 | 1,000 | 1,000 | 350 | 350 | 350 | 350 | 800 | 800 | 800 |

| Accuracy (micron) Repeatablility | 35 | 35 | 35 | 10 | 10 | 10 | 10 | 35 | 35 | 35 |

| Accuracy (micron) Volumetric | 75 | 75 | 75 | 15 | 15 | 15 | 15 | 70 | 70 | 70 |

| Camera w/ring light | >18MP | >18MP | >18MP | >18MP | >18MP | >18MP | >18MP | >18MP | >18MP | >18MP |

| Projector LED/Laser | >1MP | >1MP | >1MP | >2MP | >2MP | >2MP | >2MP | >2MP | >2MP | >2MP |

| Scanner Configuration | Carbon Fiber Tube | Carbon Fiber Tube | Carbon Fiber Tube | Common Enclosure | Common Enclosure | Common Enclosure | Common Enclosure | Carbon Fiber Tube | Carbon Fiber Tube | Carbon Fiber Tube |

| Scanner Mounting | Tripod | Light Table | Light Table | Tripod | Light Table | Light Table | Light Table | Tripod | Light Table | Light Table |

| Back-Light Table | No | Yes | Yes | No | Yes | Yes | Yes | No | Yes | Yes |

| Enclosure | No | No | No | No | Yes | Yes | Yes | No | No | No |

| Component Repositioning (2) | No | Motorized | Manual | No | Motorized | Motorized | Manual | No | Motorized | Manual |

| Scanner Repositioning (3) | No | Fixed | Fixed | No | Manual | Motorized | Fixed | No | Fixed | Fixed |

| Markers (4) Set of 24 | Std | Option | Option | Std | Option | Option | Option | Std | Option | Option |

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.

-

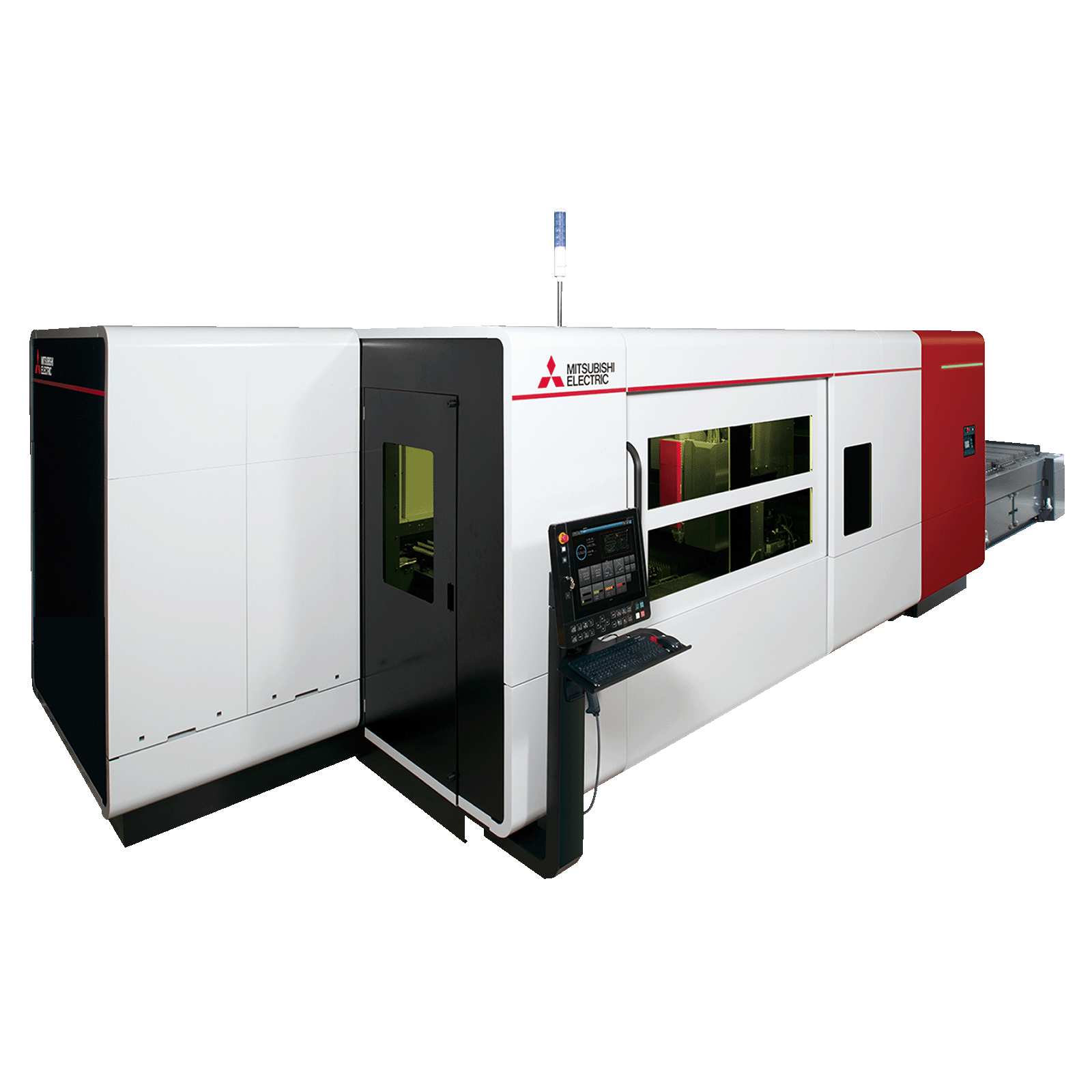

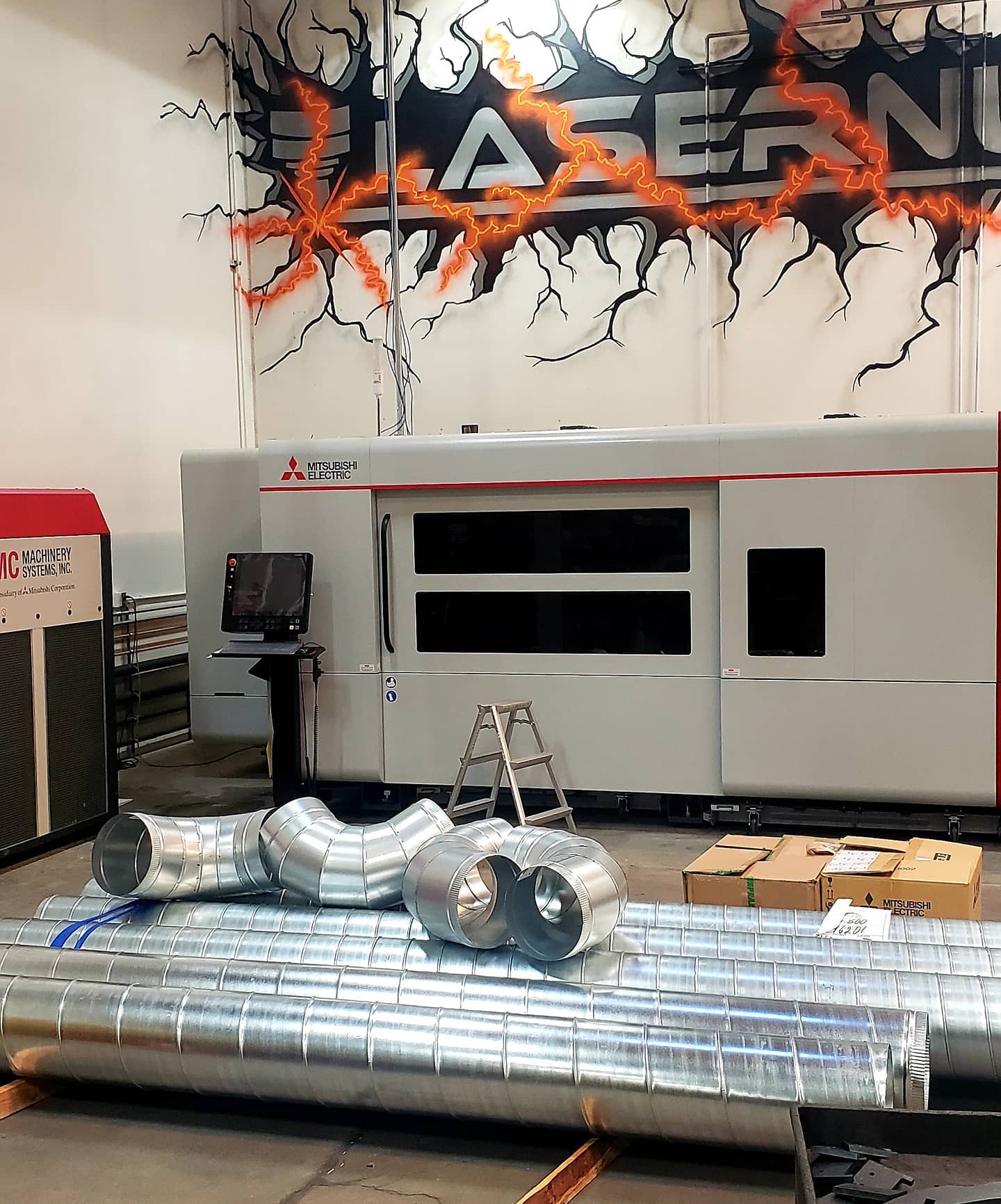

FIBER LASERS

A faster, tighter beam for higher cutting speeds and greater accuracy with thinner materials.

learn more -

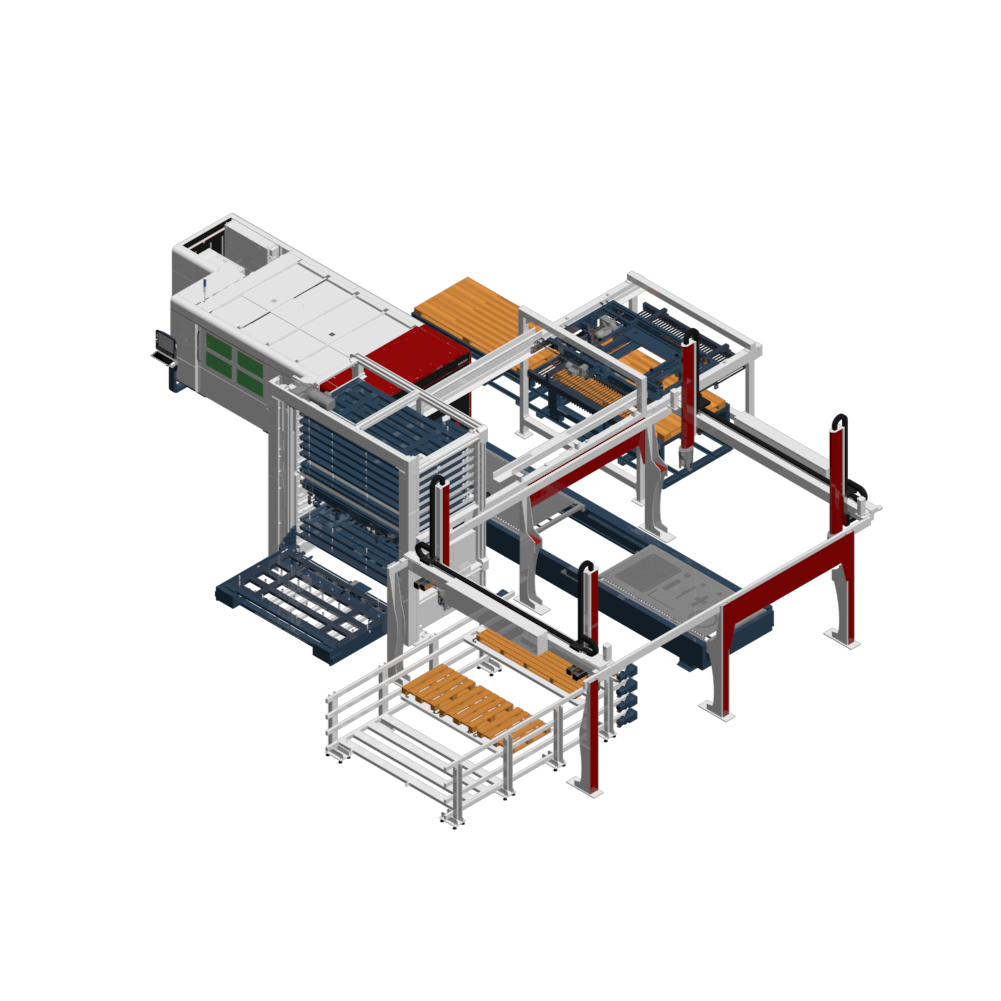

LASER AUTOMATION

Leave your bottom line beaming.

learn more -

2D CO2 LASERS

Solid construction, advanced programming, and high-speed 2D cutting for thick-cut materials.

learn more -

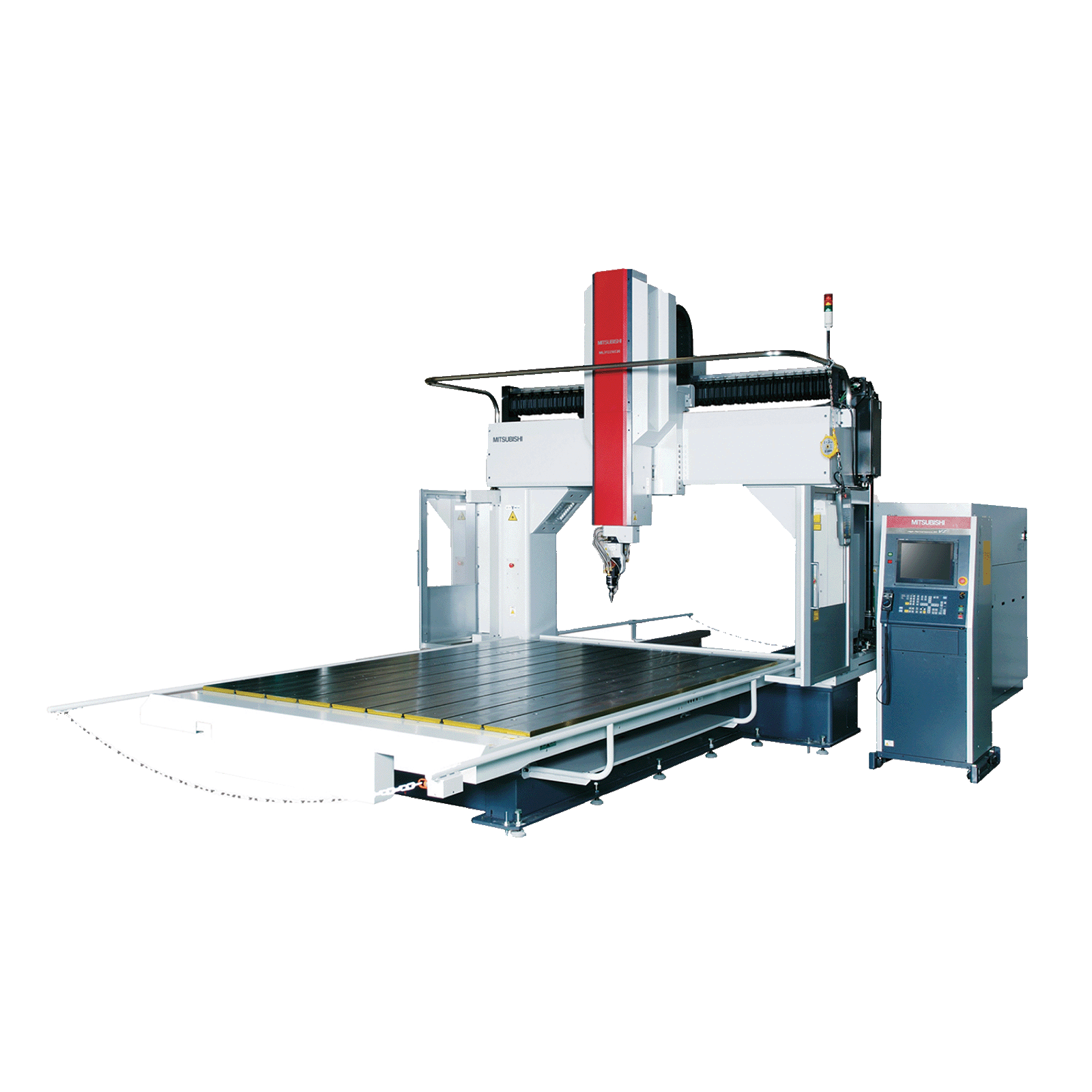

MULTI-AXIS CO2 LASERS

High-performance 3D laser processing for tough materials.

learn more

-

"We’re excited with all of the things that Mitsubishi Laser is bringing to the marketplace because it helps us achieve our goals of being profitable and having sustainable growth."

Si Cha, Olympic Steel's plant manager of the Buford location’s Fabrication Division learn more -

"It is just a mind-blowing, amazing machine. I had never been sold on fiber lasers because of micro-burr and concerns about edge quality, but the GX-F has burr reduction technology that makes burr non-existent."

Cody Waggoner, President of Lasernut learn more