InspecVision Planar 2D

High-speed measurement and reverse-engineering capabilities that take the pain out of processing.

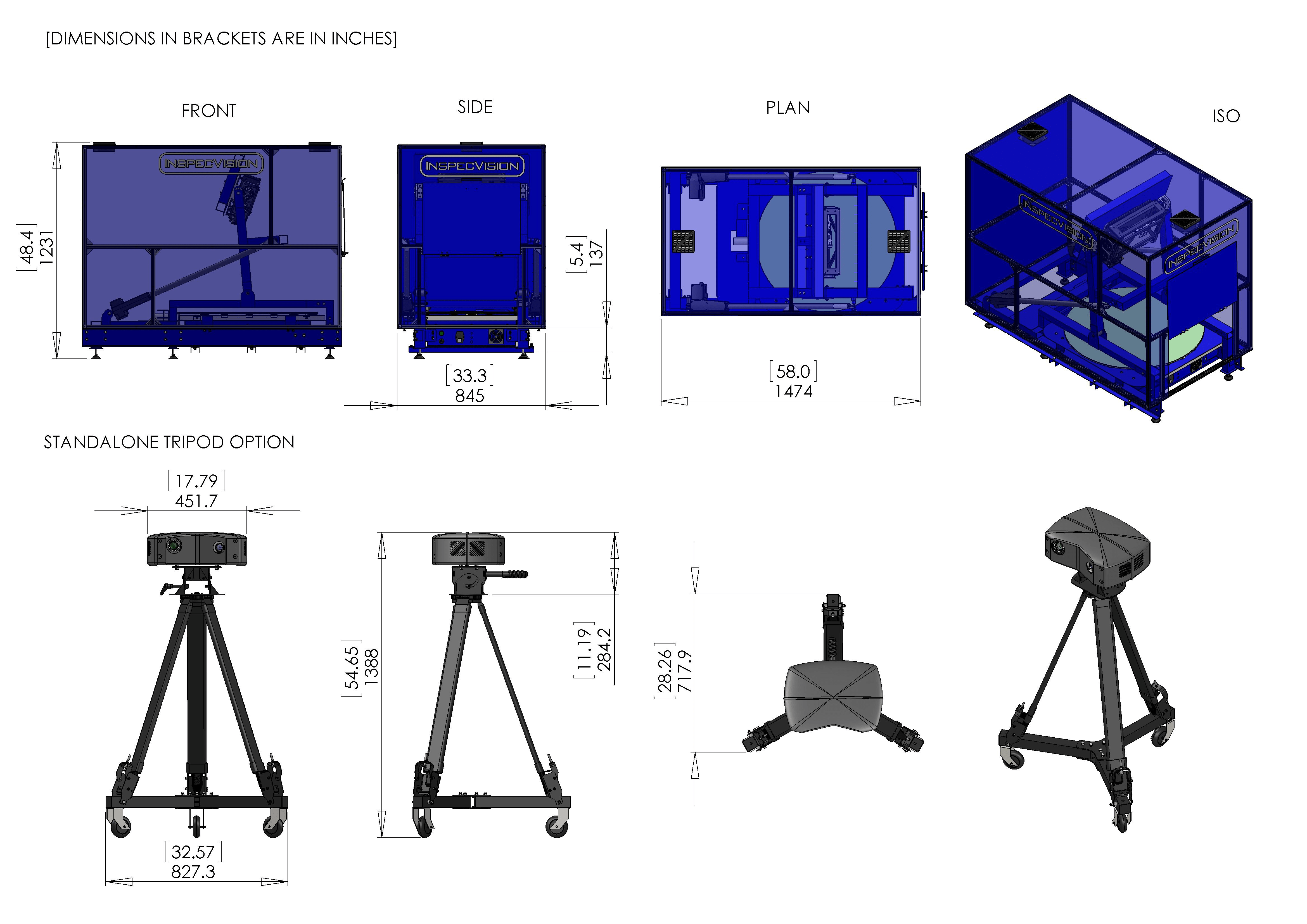

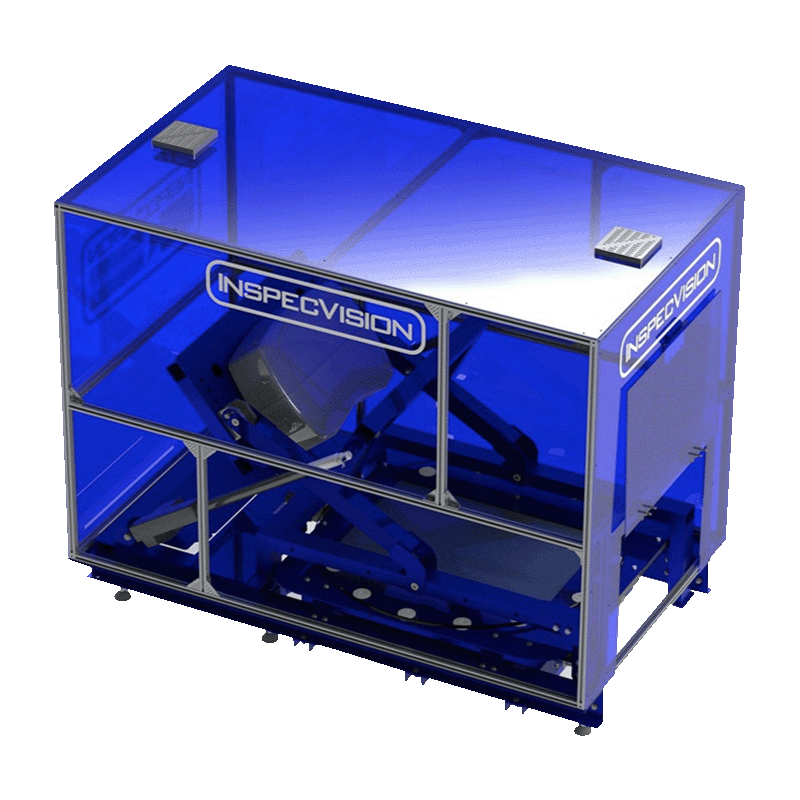

The InspecVision Planar is a 2D inspection machine that allows manufacturers to simply and quickly verify product quality, perform highly precise 2D inspection, create CAD comparisons, and assist in reverse engineering—all in a matter of seconds.

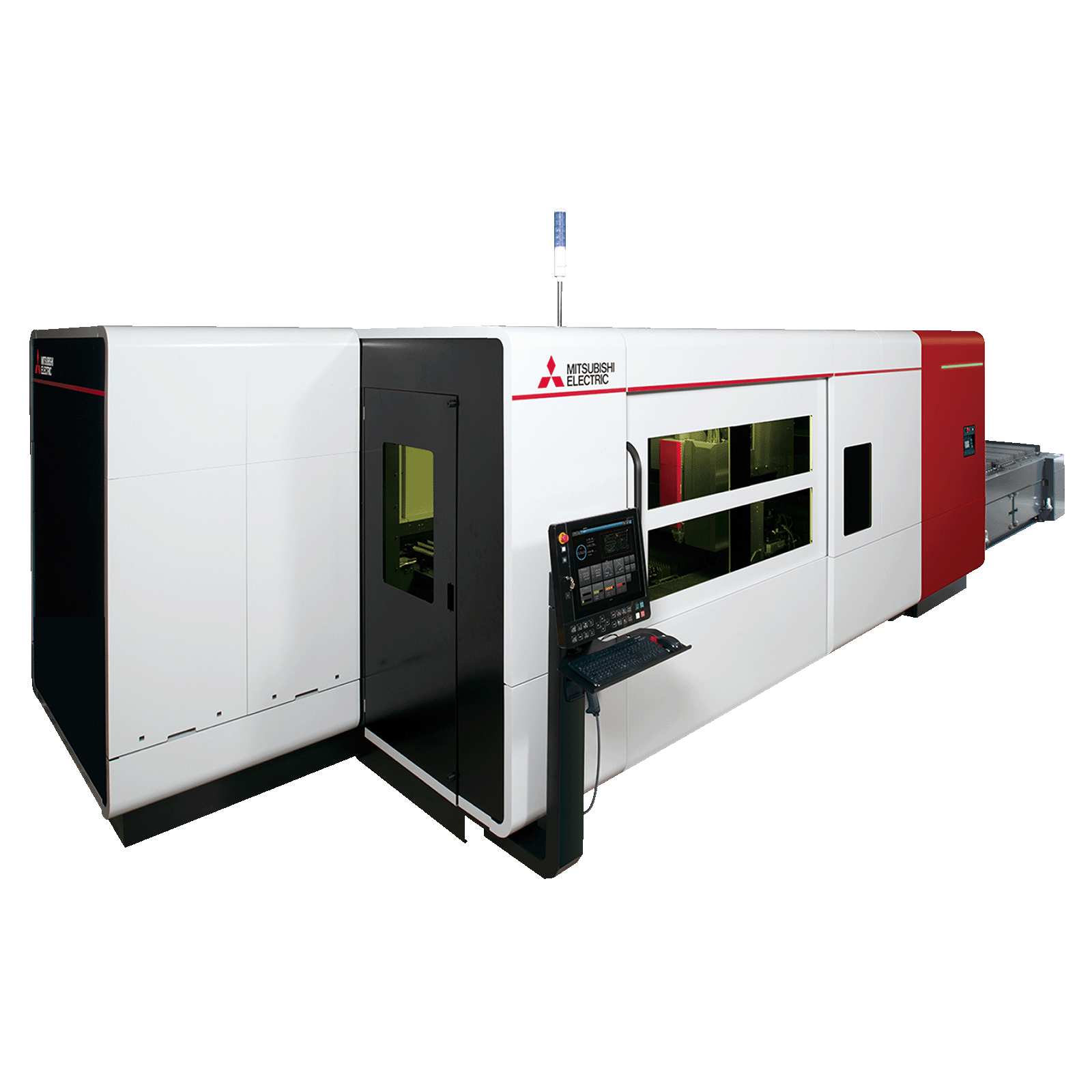

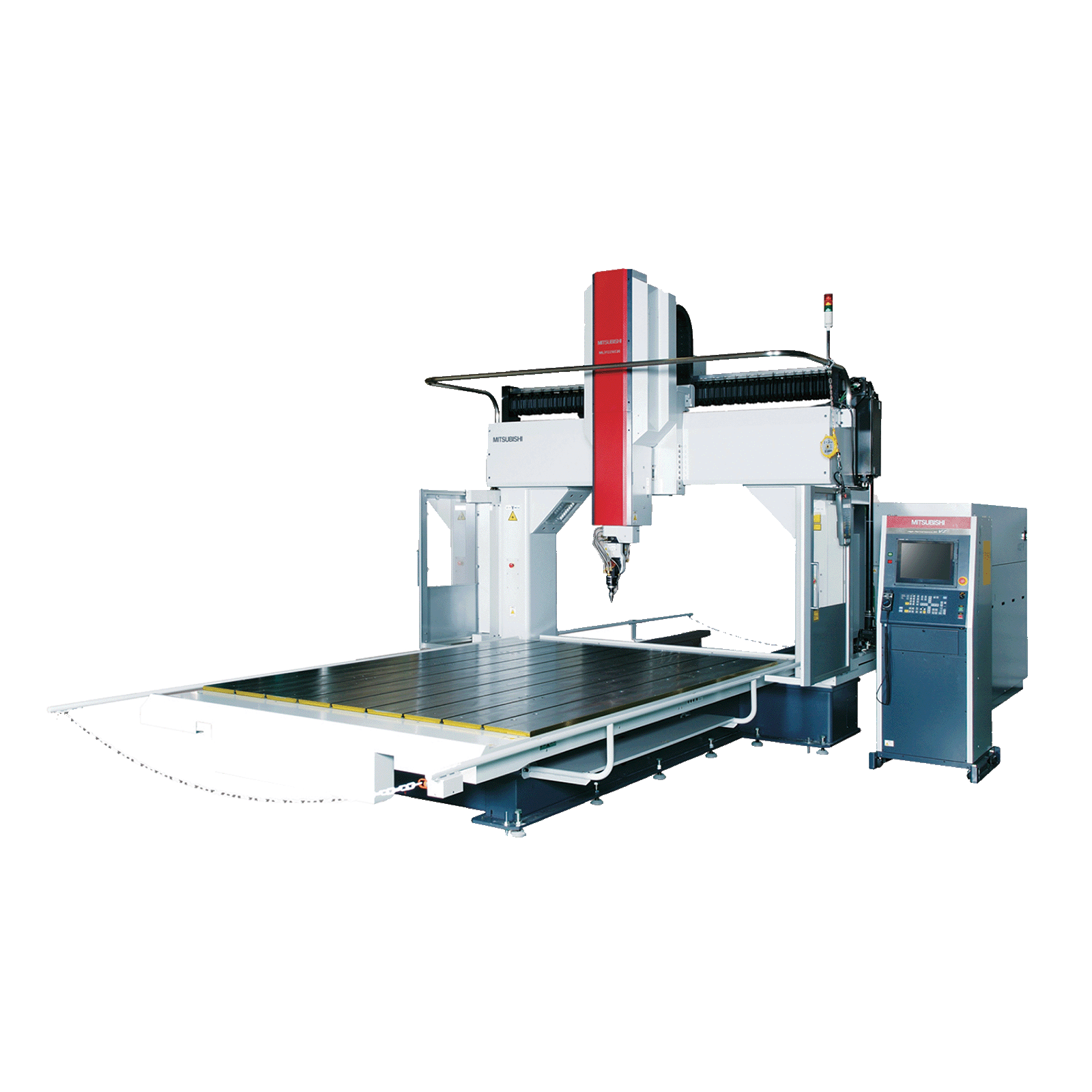

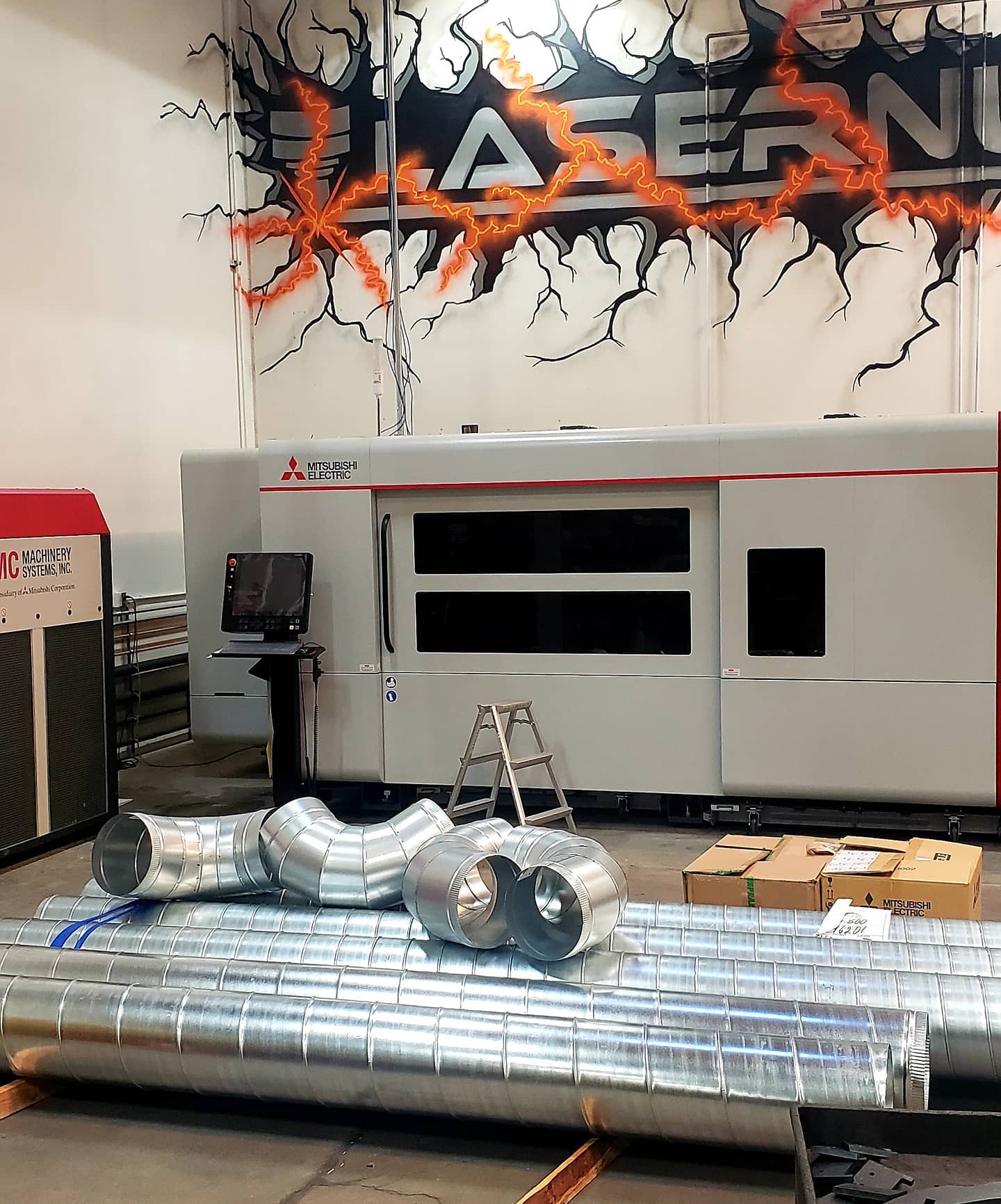

Planar customers range from small job shops to multibillion-dollar turnover companies, covering almost every industry that uses sheet metal, such as electronics and communication industries, automotive, and aerospace. The system can be used for very quickly measuring or reverse-engineering flat parts that have been manufactured on laser, plasma, and waterjet cutting systems as well as some punched and stamped parts.

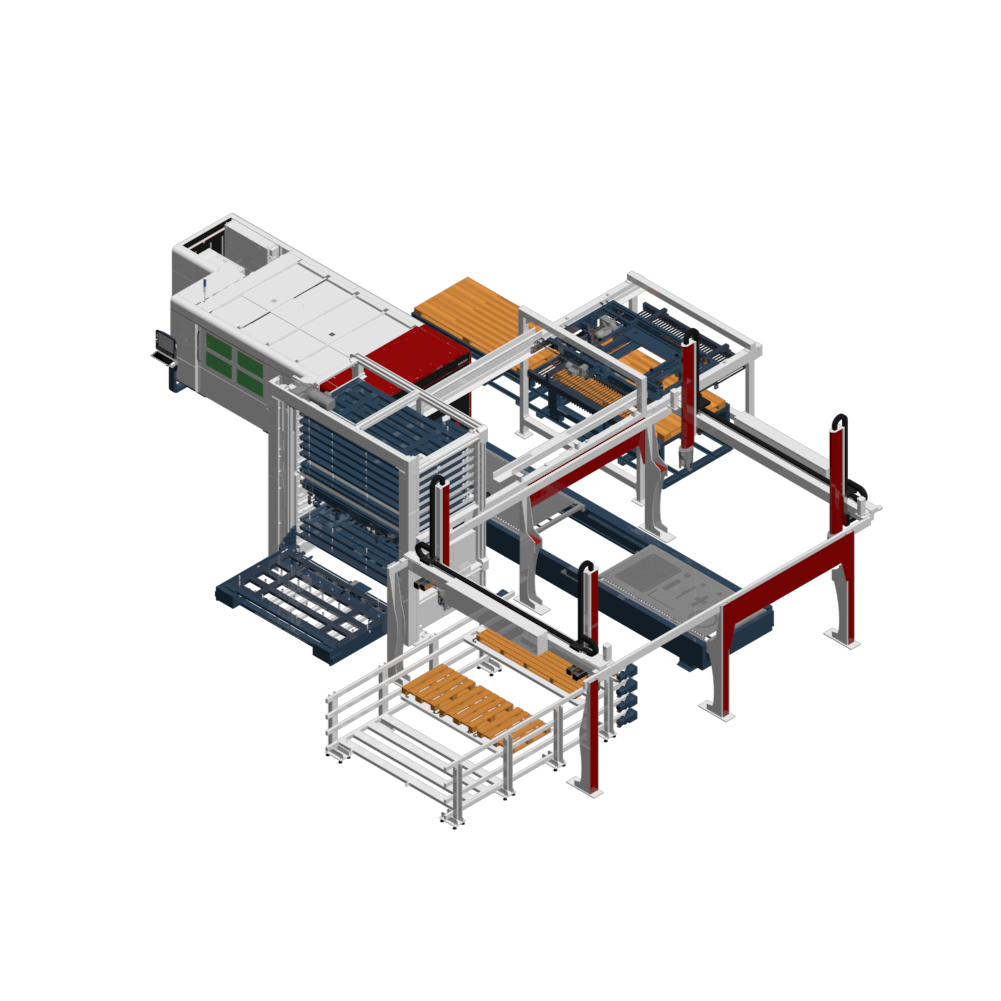

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.