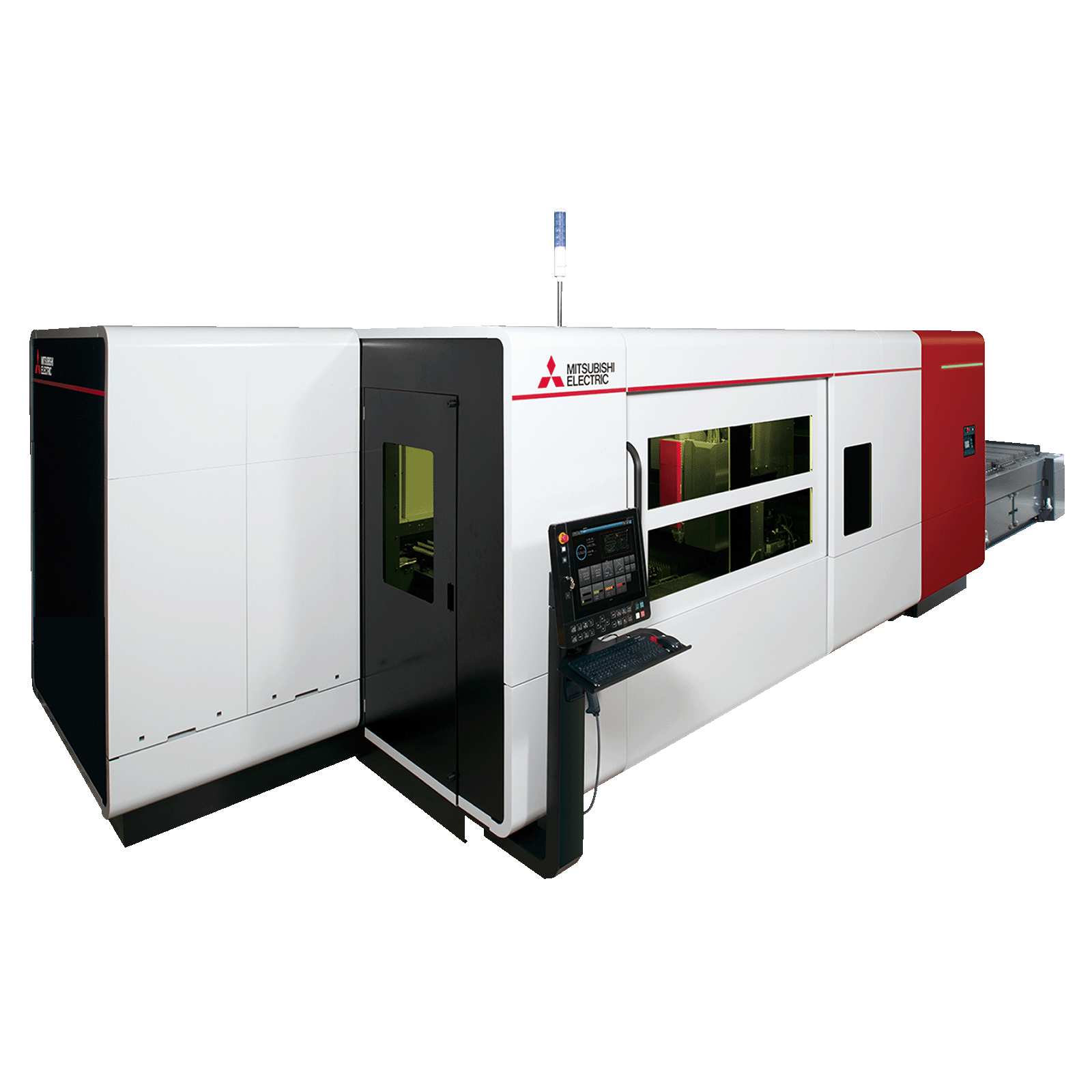

CENIT for 3D Lasers

The fastest, most intuitive way to securely unlock the full potential of your laser machinery.

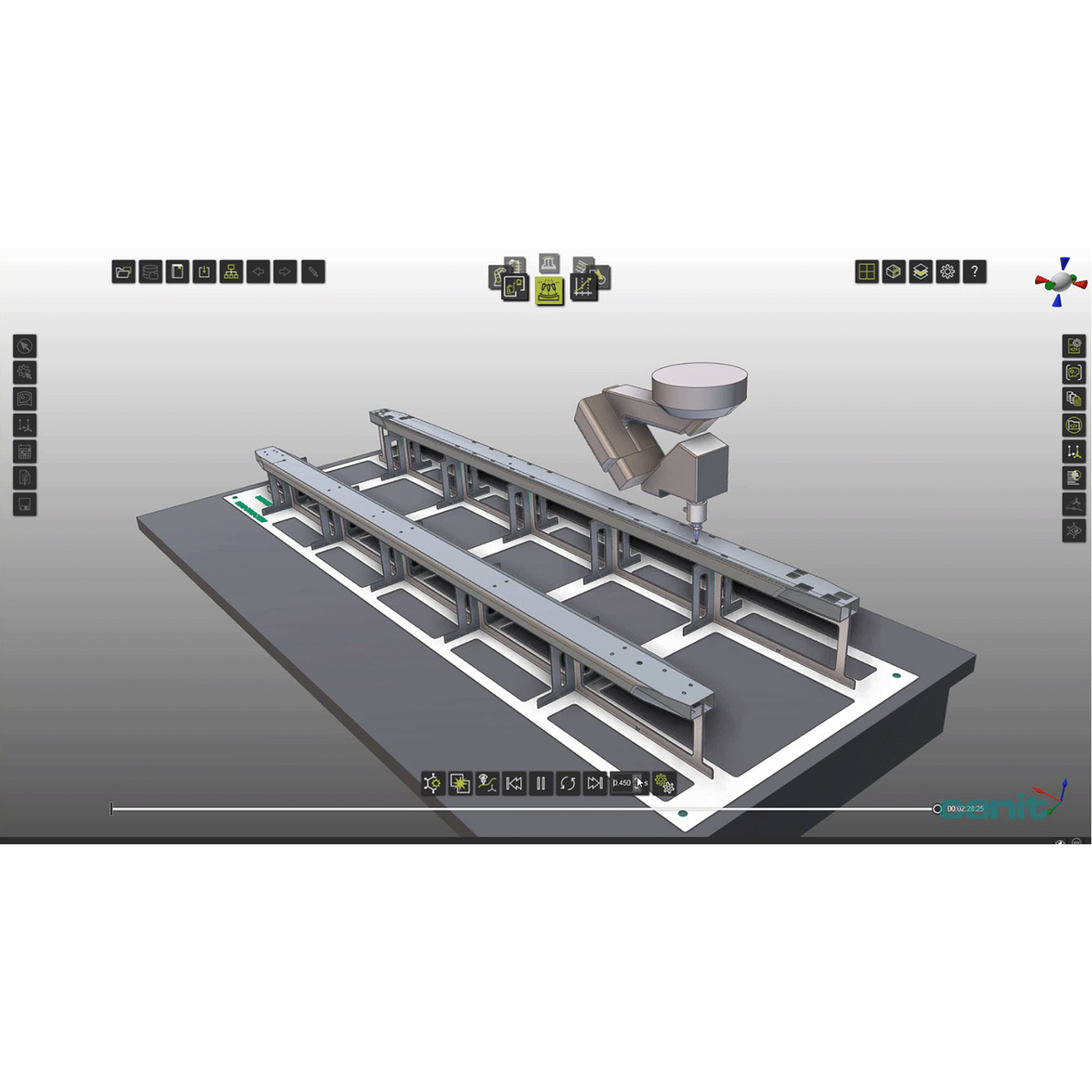

CENIT offline programming solutions cover the entire CAD/CAM and simulation components for 3D laser applications, offering improved flexibility and functionality through a robust yet accessible platform.

Other benefits include improved data handling for shorter programming times, no data conversions due to V5 integration, and advanced functionalities for sophisticated contours.

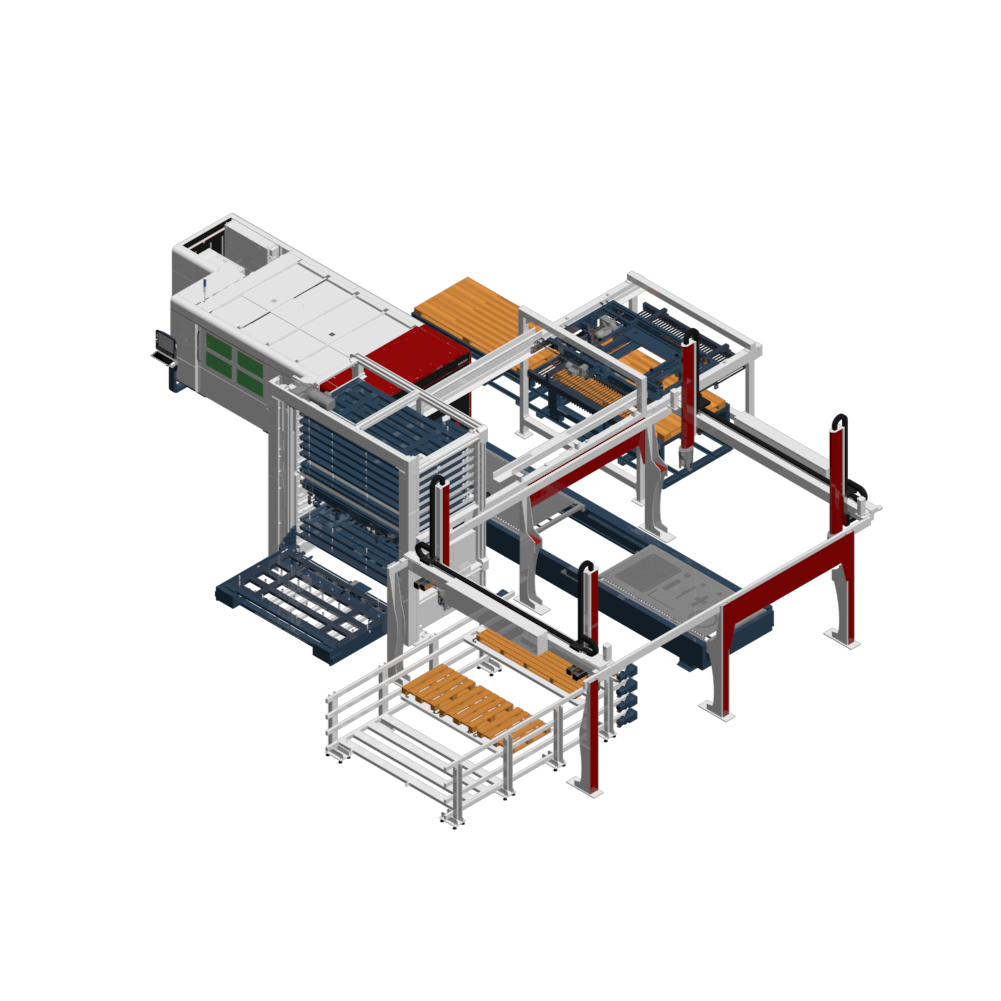

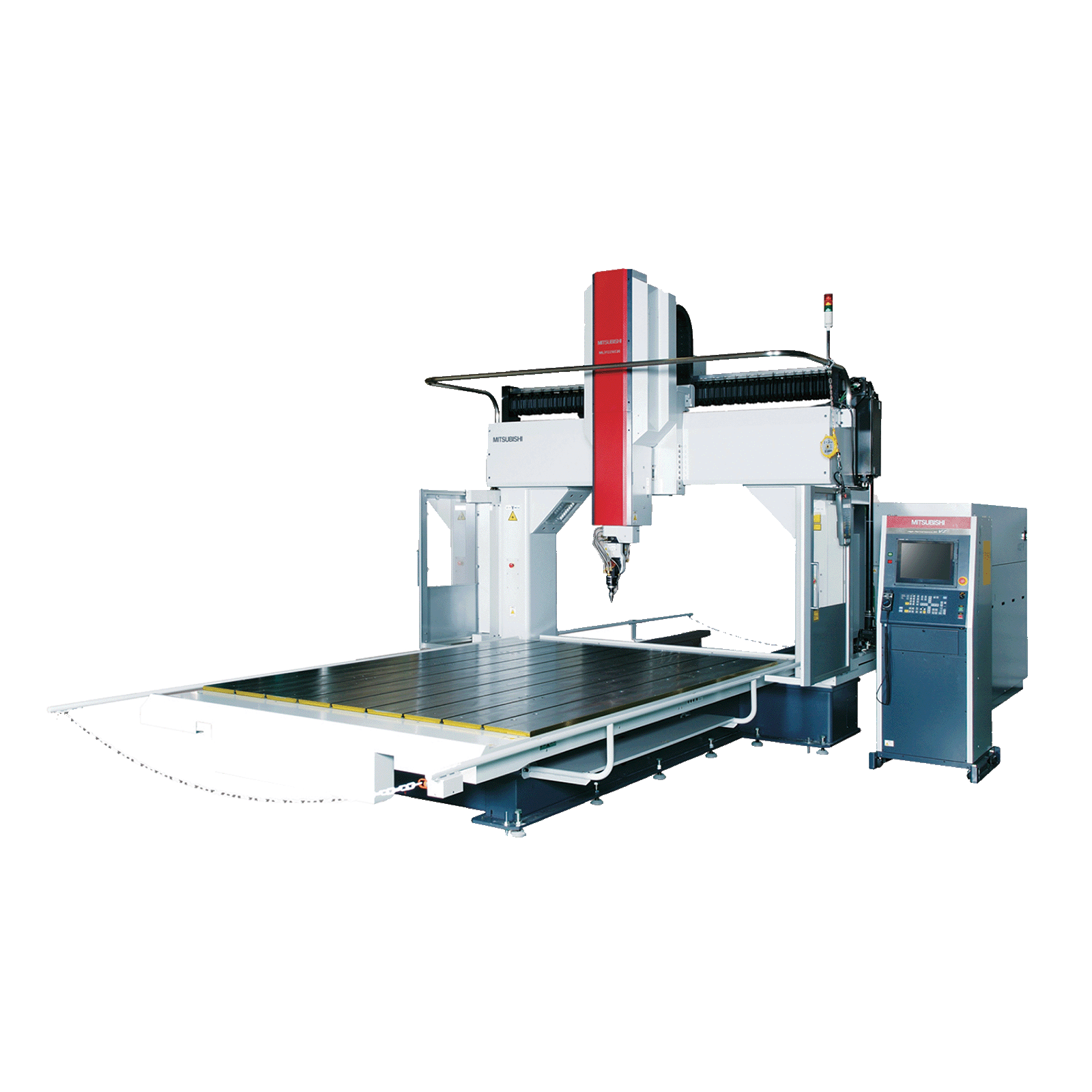

RELATED SOLUTIONS

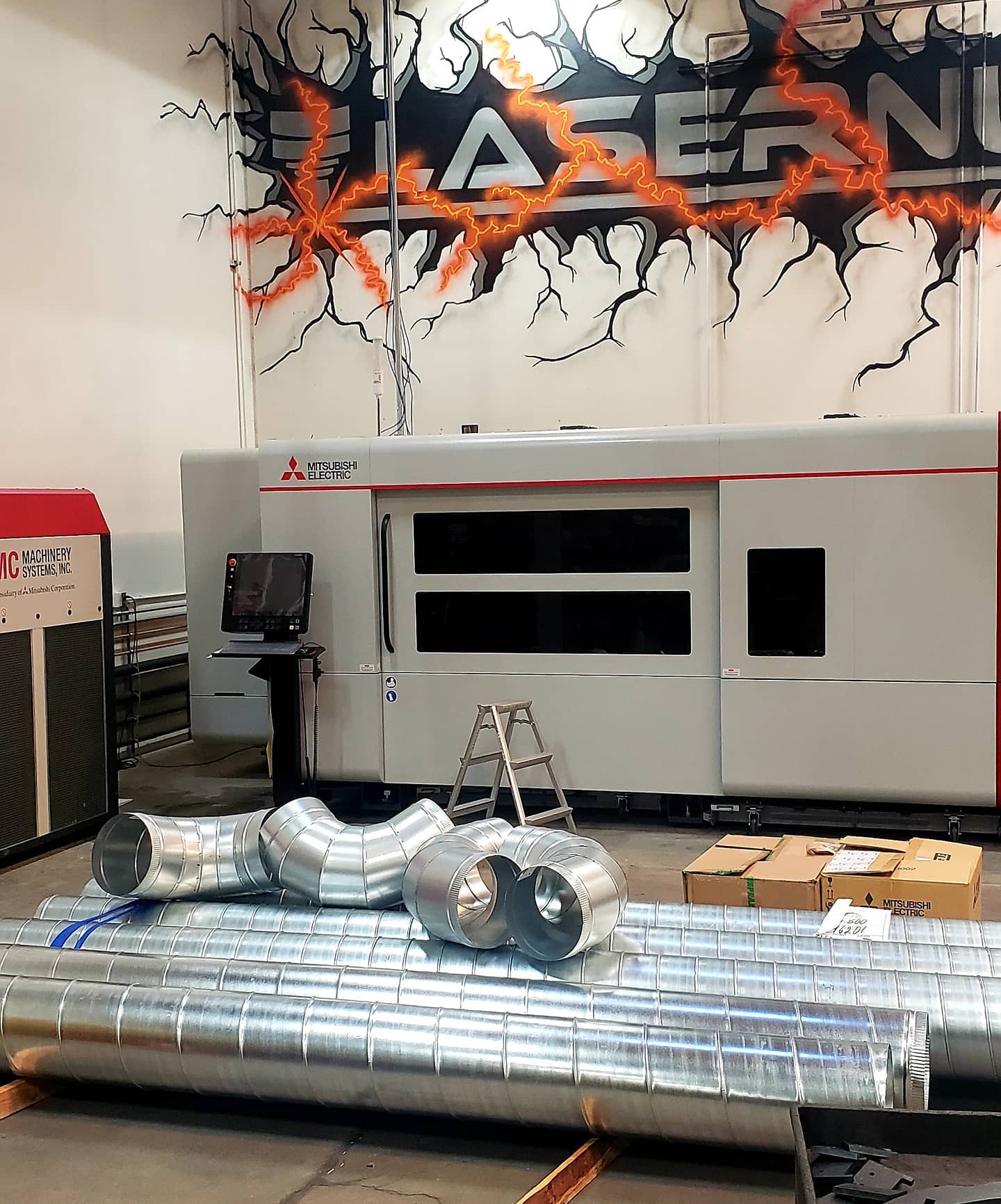

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.