GET EQUIPPED FOR SUCCESS

You know a high-functioning machine shop when you see one.

We offer solutions for virtually every aspect of metalworking from machining to fabrication—including the kind of next-generation capabilities that can transform your shop floor into a force to be reckoned with.

It’s where good work gets done fast enough to hit deadlines and well enough to exceed expectations, turning first-time customers into long-time customers.

It’s confident, capable people and reliable machines—working hard, working smart, and working together in perfect harmony, no matter what order comes through your doors.

It’s where adaptability, quality, and innovation come together like clockwork, giving you the capabilities you need to face the future of manufacturing—no mess, no stress, and very, very few mistakes.

The future of manufacturing is just around the corner. We’ll help you find the tools your business needs to get there.

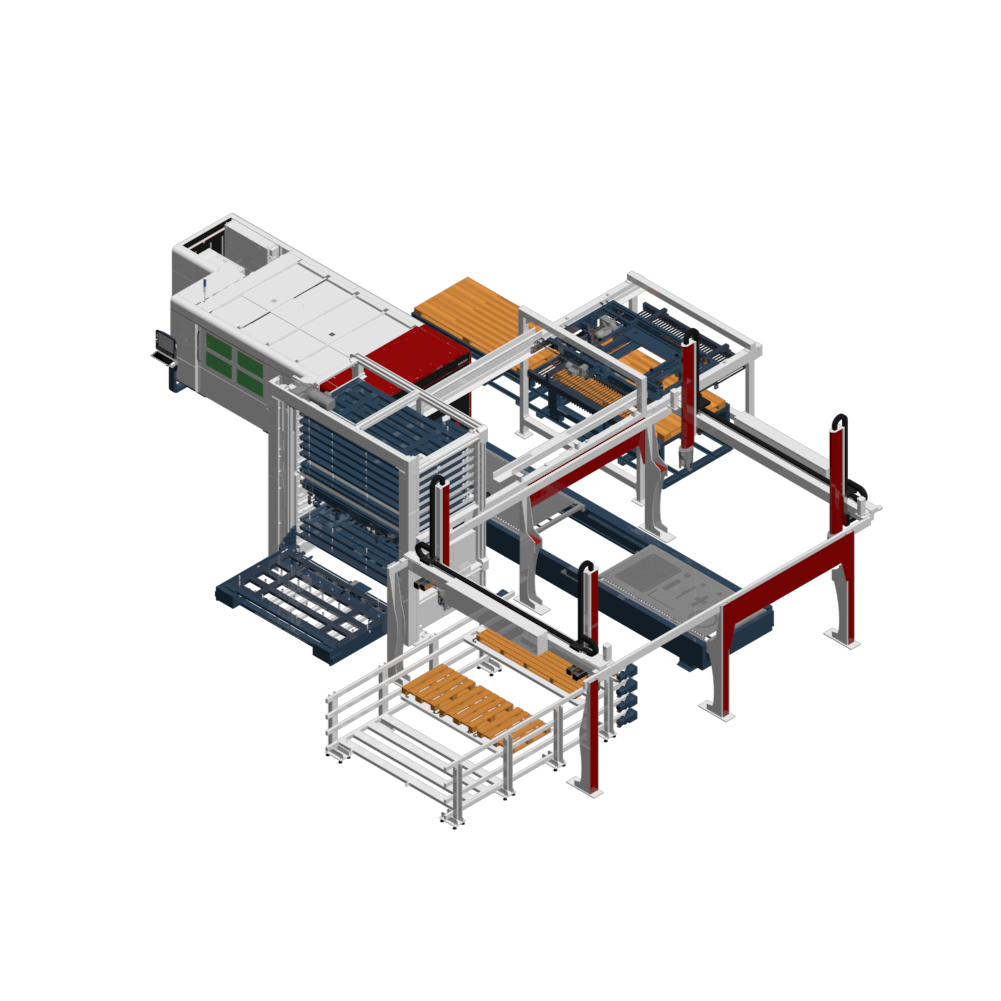

AUTOMATION

In today’s manufacturing world, the pressure is on: More extreme market demands and global competition call for faster, higher-volume, and lower-cost production.

Automation solutions—like automatic part sorting, part picking, optimizing part flow, and more—can help reduce costs and improve part quality and response times in many of your operations. They can also help you turn potential challenges into serious business advantages.

But if you think the answer to these pressing business challenges is as simple as flipping a switch, you’re only half right. It’s also about knowing which switches to flip.

But don’t worry—we can make automating your production line a lot easier, and a lot more cost-effective than you might think possible.

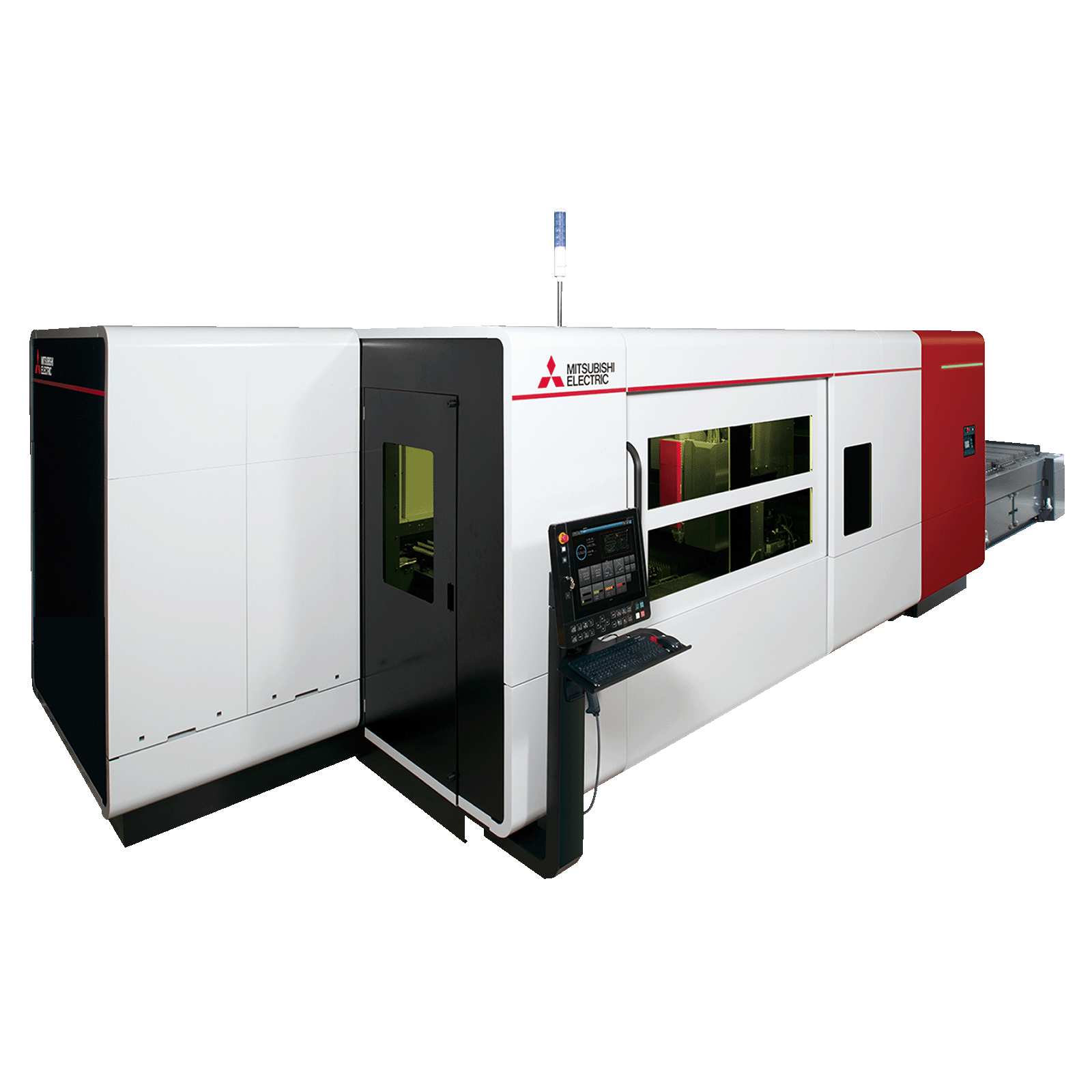

LASER

Industrial fabrication lasers are an easy, comfortable fit for any operation, and not just for their ability to cut a wide range of material compositions and thicknesses.

Lasers achieve extreme operational utility at breathtaking speeds that, combined with advanced CNC controllers for quick, intuitive work, can increase throughput with less labor.

And best of all, they’re easy to integrate with your existing floor plan or with future expansions—including automation technologies.

If you have tight precision and quality standards and even tighter timelines, laser cutting machines from MC Machinery are here to deliver.

MILLING

Milling, or the process of removing materials via physical contact with a rotating cutting edge, may be the most common form of machining. But the right machine—one that’s easy to use, maintain, and support—can deliver truly uncommon work quality, not to mention other benefits to your business that are nothing short of extraordinary.

When the job calls for complex parts, micro-machining, or uncompromising maneuverability, milling machines deliver results that stand out.

From versatile, cost-efficient solutions for general milling applications to fast, sophisticated 3D milling machines ideal for tight-tolerance and high-speed jobs, we’ve got you covered.

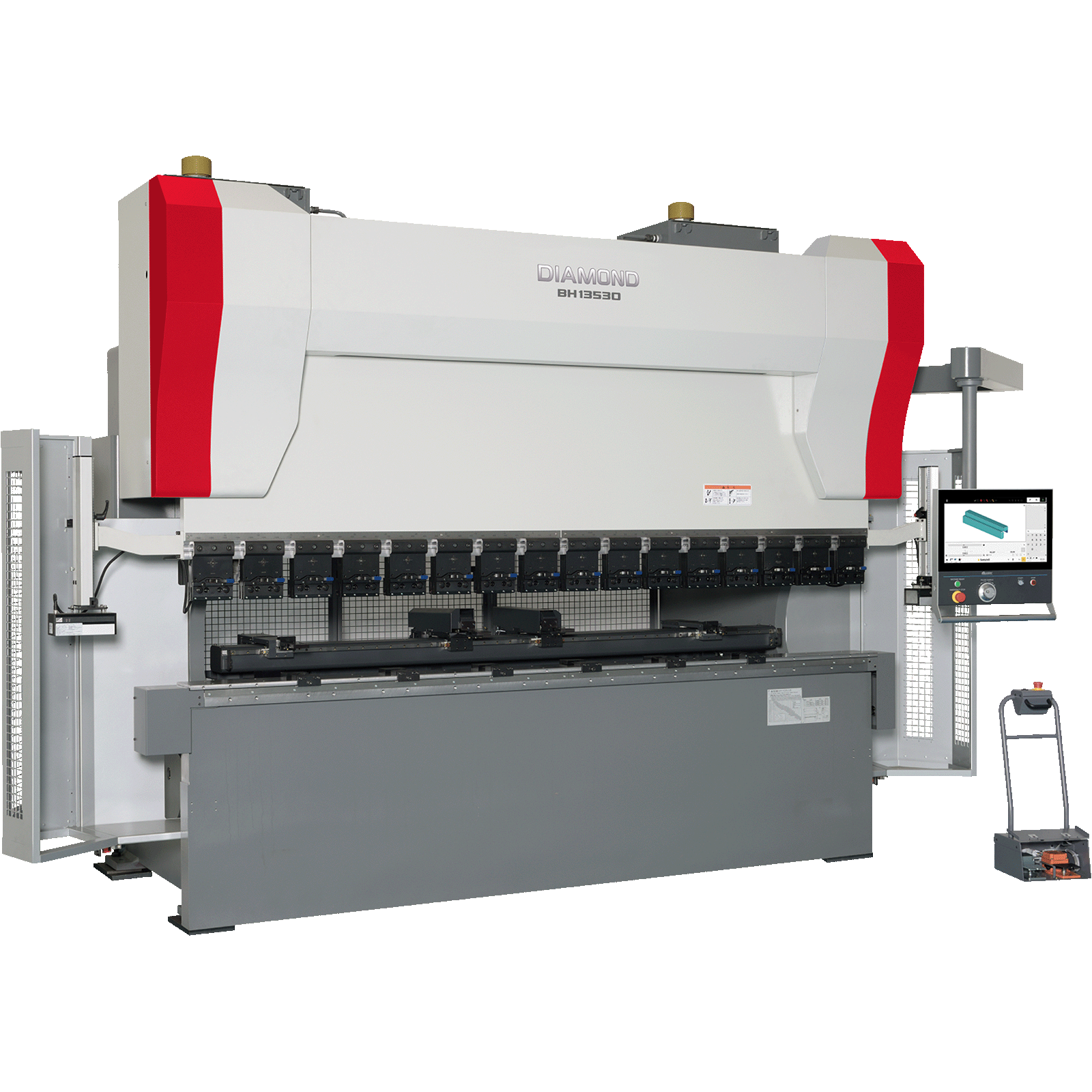

PRESS BRAKE

Press brake machines play a crucial role in just about any machine shop.

Fabrication shops depend on fast, reliable press brake machines. But despite how much bending these workshop workhorses do, the identifying factors of a truly excellent press brake machine are set in stone.

To ensure maximum efficiency, they need to be easy to use. And to keep projects moving and profit margins looking healthy, they need to fit in seamlessly with the rest of your production line.

But there are all kinds of other critical factors that can make or break your productivity.

SHEARS

For bringing high quality craftsmanship to sheet metal of all kinds of material and thicknesses—with clean cuts and smooth edges—at high volumes, a hydraulic shear can’t be beat.

But finding the right shear for your shop floor isn’t as simple as that. With the future of industrial fabrication fast approaching, today’s machine shops are faced with old challenges and exciting new opportunities to streamline, improve, and grow their production capabilities.

Through a truly unique combination of cost-effective construction that’s both easy to use and train on and the ability to integrate with new automation technology, our shears pack enough punch to give your business a serious edge.

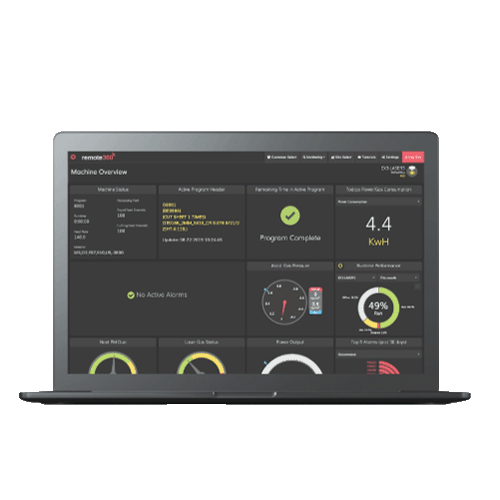

REMOTE MONITORING

Innovation is on the rise. Consumer preferences are changing. Managing resources—from material to manpower—is more critical than ever.

To find the secret to meeting and beating these challenges, you’ll need a couple of key advantages:

Smart, efficient machines that make leaner, meaner operation quick and easy. Data-driven insights to predict and preempt challenges before they become problems—a deeper connection to the heart of your shop floor.

Let’s go under the hood.