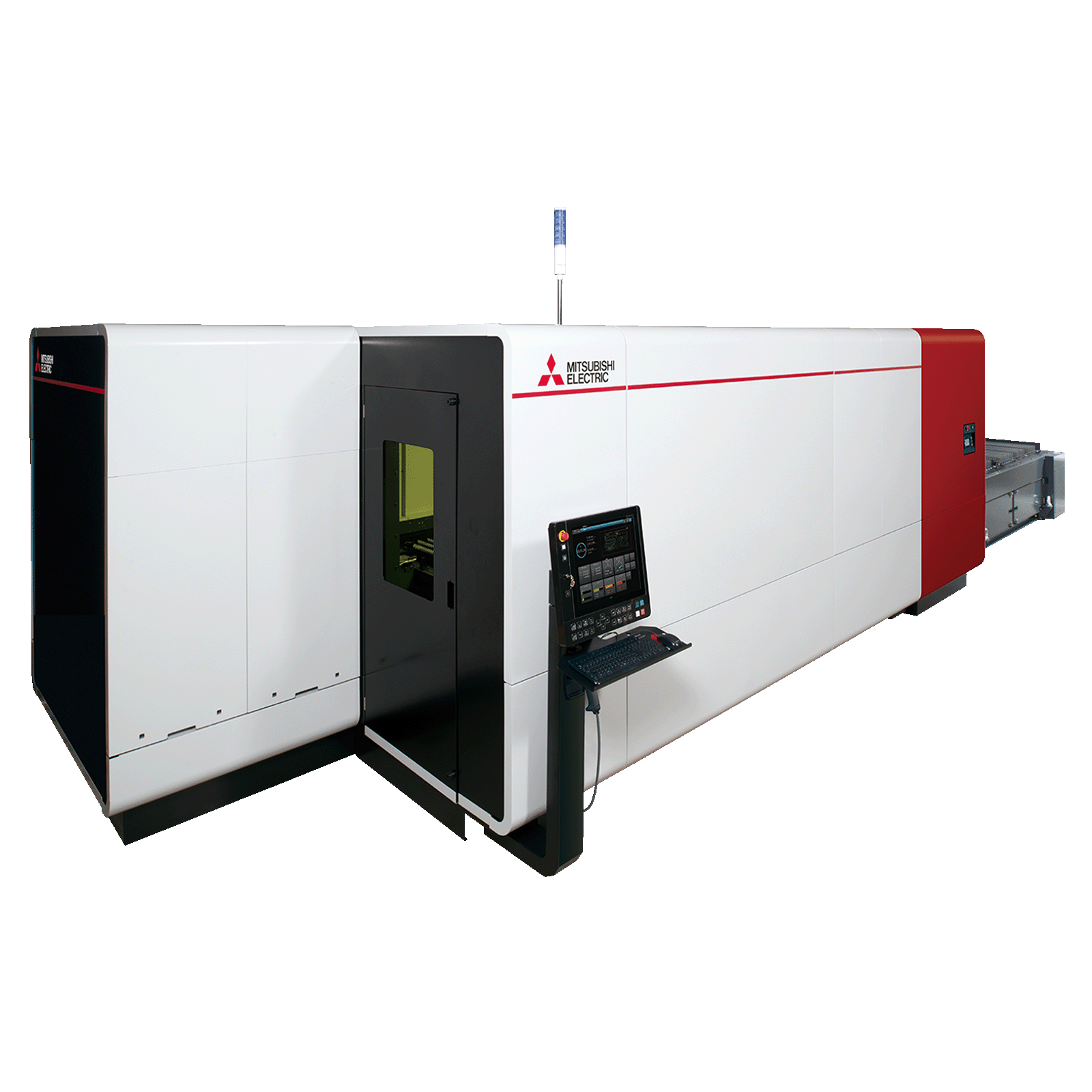

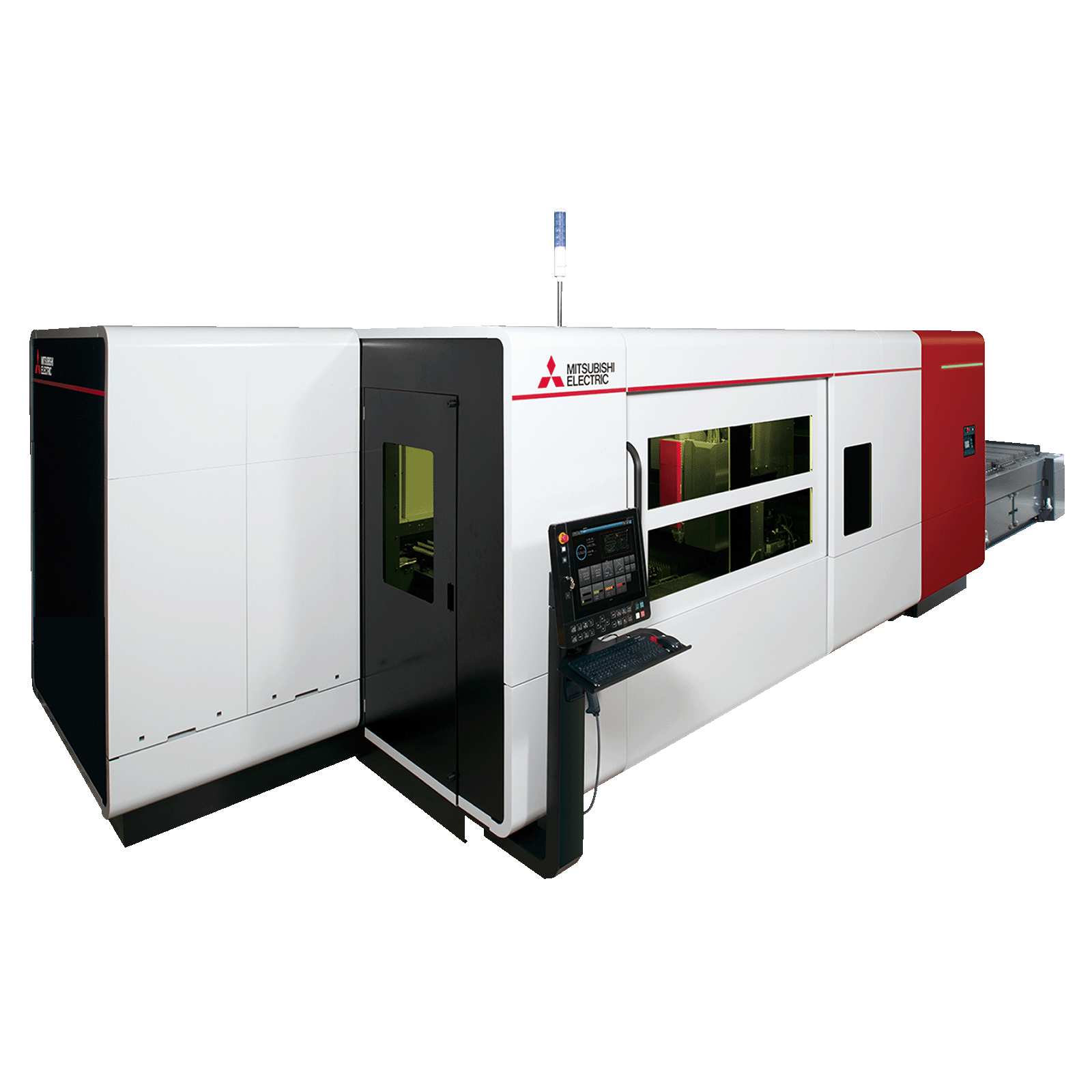

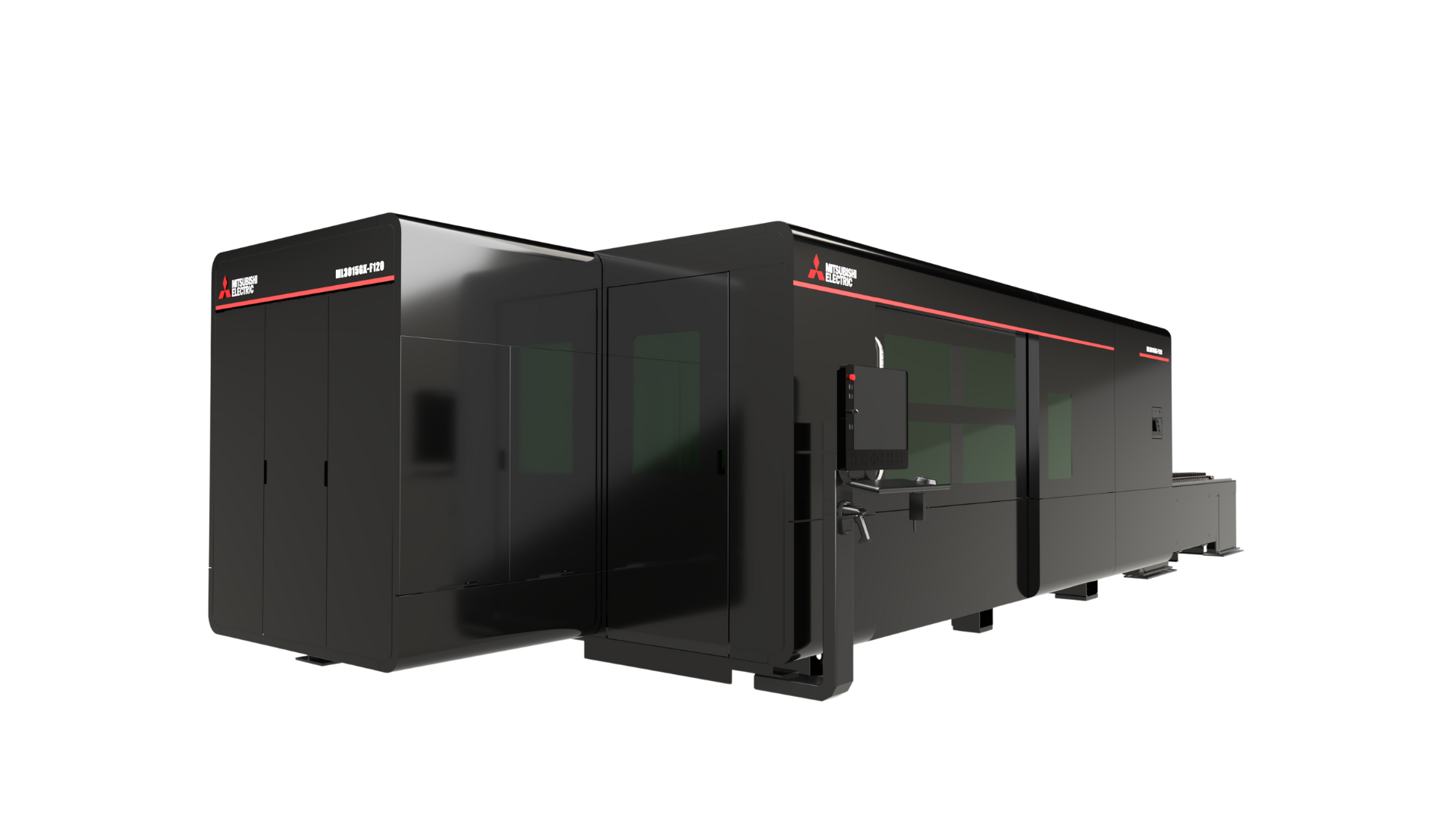

GX-F ADVANCED PLUS Series

The GX-F ADVANCED PLUS is Mitsubishi’s most advanced fiber laser cutting system, designed to reduce operator input while maximizing speed, accuracy, and efficiency. Built entirely with Mitsubishi components, it delivers unmatched reliability and performance.

Core innovations include Automatic Centering with a 21-position nozzle changer, Direct Sense height control with automatic collision avoidance, and the proprietary Zoom Head, which adapts beam shape and focus for any material or thickness. Augmented Reality Plus nesting allows drop cut, part rotation, and part-in-part placement to simplify setup and reduce scrap.

With AI process monitoring, the system automatically adjusts cutting conditions in real time, ensuring stable, high-quality performance and reducing downtime. Added features like Dynamic Drive Control, Dross Reduction Control, Plasma Guard, High Peak Piercing, Mel’s Eye detection, and Process Monitoring further enhance stability and cut quality.

The advanced AGR (Advanced Gas Reduction) family (AGR-N2, AGR-MIX, AGR-O2, and AGR-AIR) cuts assist gas use by up to 75%, lowering costs while maintaining superior quality and boosting productivity.

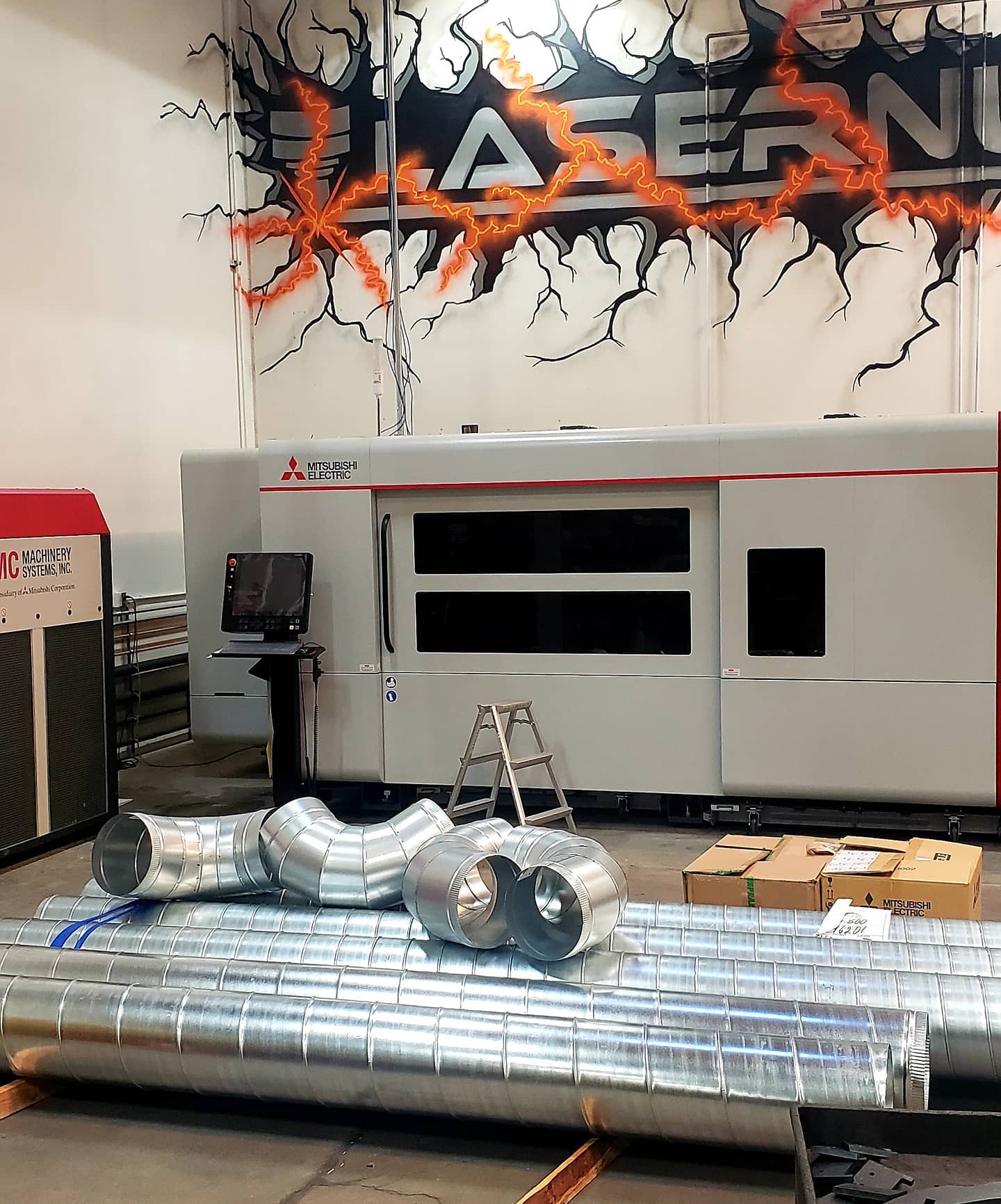

Fully automation-ready, backed by Remote360™ monitoring, predictive maintenance, and a five-year oscillator warranty, the GX-F ADVANCED PLUS sets a new benchmark for intelligent laser cutting.

Less input. More output. One source. Endless expertise.

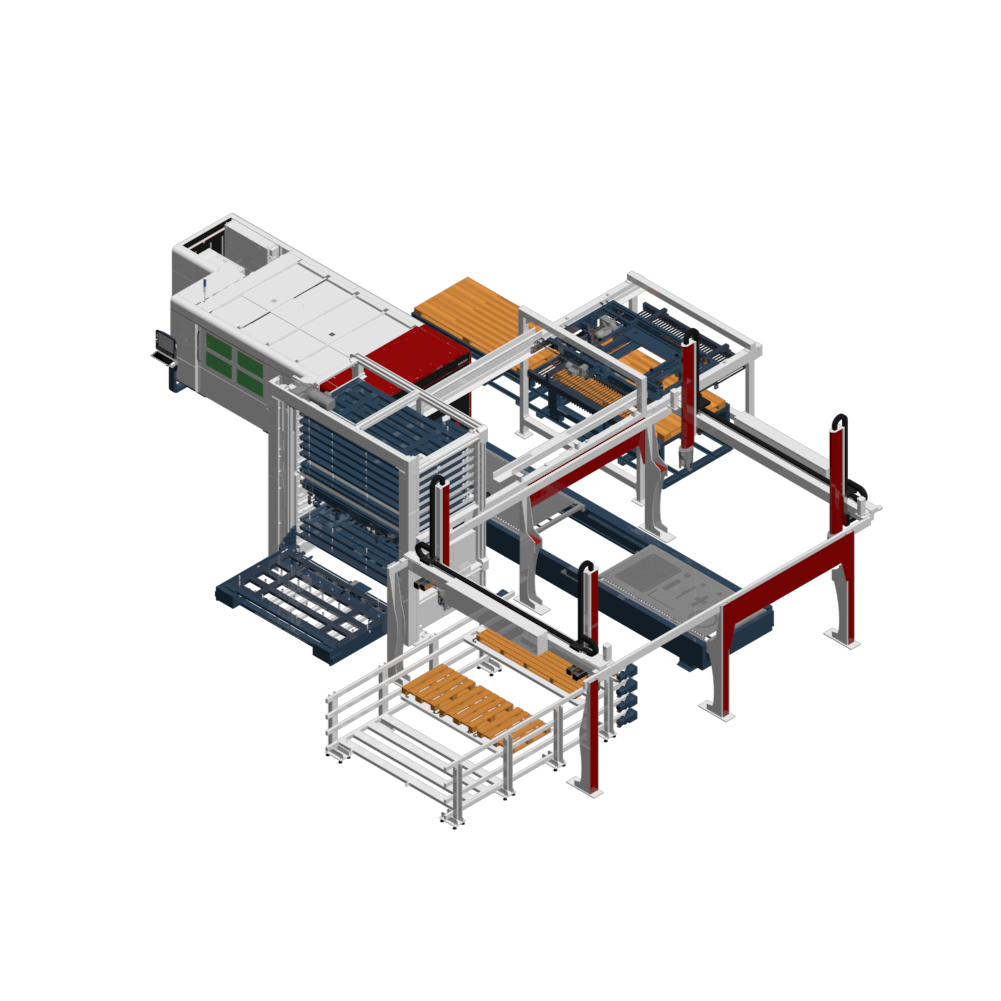

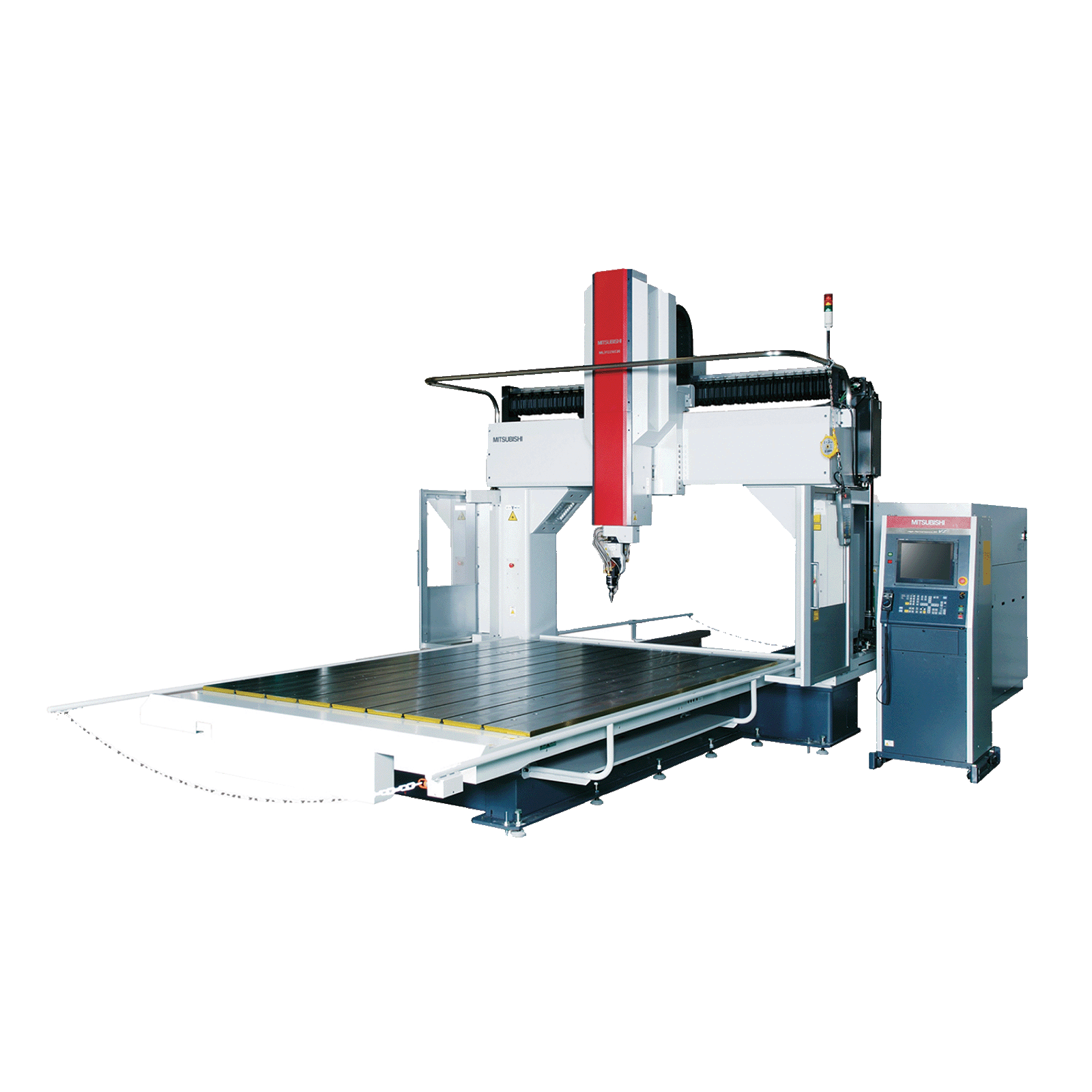

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.