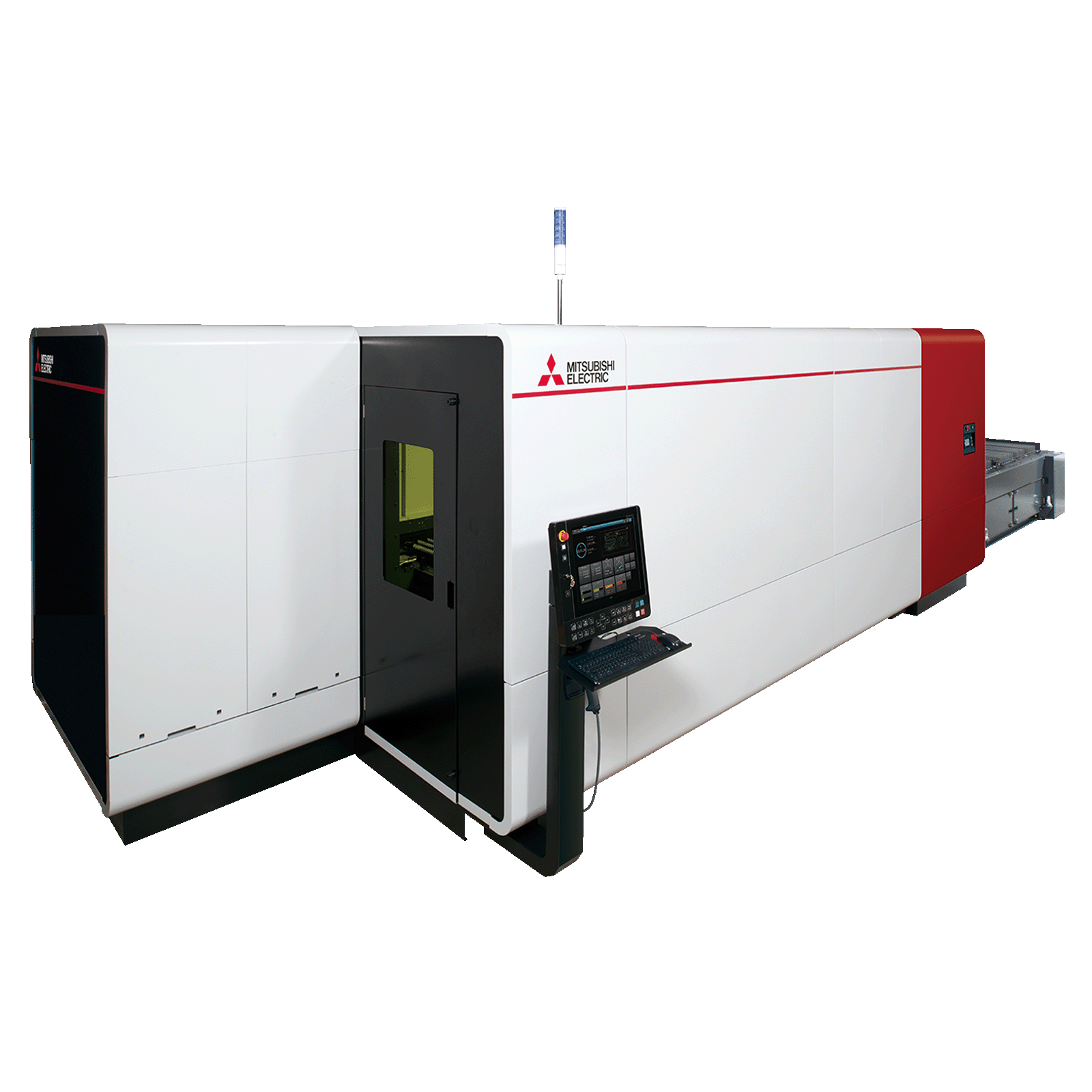

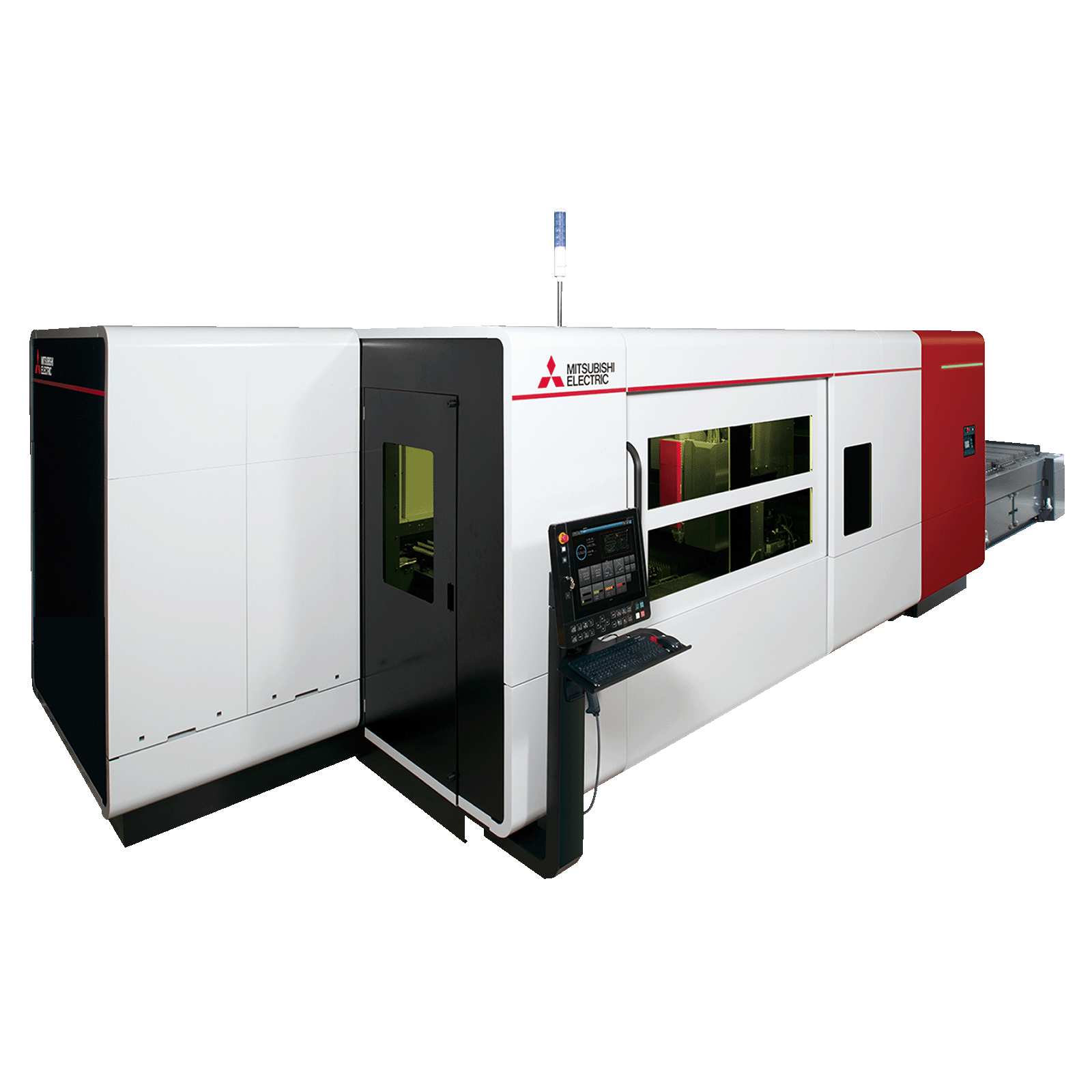

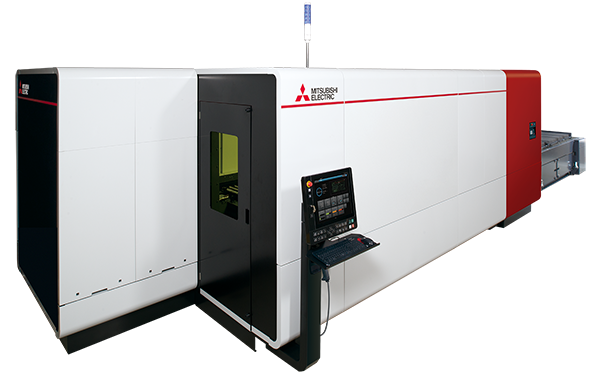

GX-F Series

Designed by Mitsubishi engineers and built with Mitsubishi components, the GX-F Series is one of the only laser cutting systems in the industry with a single source for service and support.

The new Mitsubishi GX-F Series of two-dimensional fiber lasers delivers more power while using less nitrogen, translating into lower operating costs and higher profitability. These state-of-the-art lasers are easy to operate no matter the skill level, with intuitive, smartphone-like controls and faster, more stable processing that delivers consistent beam quality.

• User-friendly, smartphone-like controls

• Major components built by Mitsubishi

• High processing stability with superior beam-quality consistency

• Beam cleaning and anti-reflection technologies

• Faster processing and more stable processing

• Reduced operator input

• No setup time between materials

• Lower operating cost translates into higher profitability

• Longer consumables life

• No material-surface scratching

• Optimized cutting speed

• On-site or remote monitoring of cutting process

• Reduced piercing time

• Remote diagnostics and predictive maintenance

• Single-source, robust training, service and support

• Easy integration with automation systems

• Five-year oscillator parts warranty

• Two-year machine tool warranty

• Two years of remote360™, Mitsubishi’s advanced machine monitoring system

• Installation and training

USER INTERFACE

The intelligent M800 control offers a generous 19-inch user interface. The status of the machine and

Work can be displayed simply on one screen or as a detailed analysis, whichever the operator desires.

Key features include:

• Intuitive, user-friendly operation similar to a smartphone

• Customizable home screen

• Real-time condition adjustment and correction

• Intelligent cutting assist

• Simple multi-part nesting

• Online job scheduling and runtime estimator

• Automatic sheet detection

• Scrap cutting

• Real-time tracking of electric and assist gas consumption

• Micro-tabbing on the fly

• Advanced help and maintenance screens

• The operator can monitor the cutting process from the machine or remotely

| Machine Specs | ||

| Available Platform | ML 3015 GX-F | ML 4020 GX-F |

| Machine Structure | Weld Bonded Chassis with Precision Helical Rack & Pinion, Direct Drives | |

| X – Axis Stroke | 122.0” (3100mm) | 161.41” (4100mm) |

| Y – Axis Stroke | 61.61” (1565mm) | 82.67” (2100mm) |

| Z – Axis Stroke | 4.72” (120mm) | 4.7” (120mm) |

| Maximum Work Piece Size | 120.1” (3050mm) x 60.0” (1525 mm) | 159.44” (4050mm) x 81.10” (2060mm) |

| Maximum Processing Feed Rate | 3937 in/min (100 m/min) | 3937 in/min (100 m/min) |

| Maximum Work Piece Weight | 2094 lbs. (950 kg) | 3637 lbs. (1650 kg) |

| Table Pass Height | 35” (890 mm) | 35” (890mm) |

| Rapid Travel Speed | 6700” (170 m/min) simultaneous | 6700” (170 m/min) simultaneous |

| Positioning Accuracy | 0.0019”/20” (0.05/500 mm) | 0.0019”/20” (0.05/500 mm) |

| Repeatability | ±0.00039” (0.0099 mm) | ±0.00039” (0.0099 mm) |

| Machine Unit Dimensions | 415.0” (10541mm) x 135.0” (3429mm) | 487” (12376mm) x 140” (3560mm) |

| Machine Weight (No Pallet Changer) | 15432 lbs. (7000 kg) | 20943 lbs. (9500 kg) |

| Pallet Changer Weight | 5291 lbs. (2400 kg) | 8900 lbs. (4037 kg) |

| Oscillator Specs | ||

| Manufacturer | Mitsubishi Electric | Mitsubishi Electric |

| Excitation Method | Ytterbium Doped Fiber | Ytterbium Doped Fiber |

| Wavelength | 1.07µm | 1.07µm |

| Available Output Power (CW) | 4 kW , 6 kW | 4 kW , 6 kW |

| Processing Head | Zoom | Zoom |

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.

-

FIBER LASERS

A faster, tighter beam for higher cutting speeds and greater accuracy with thinner materials.

learn more -

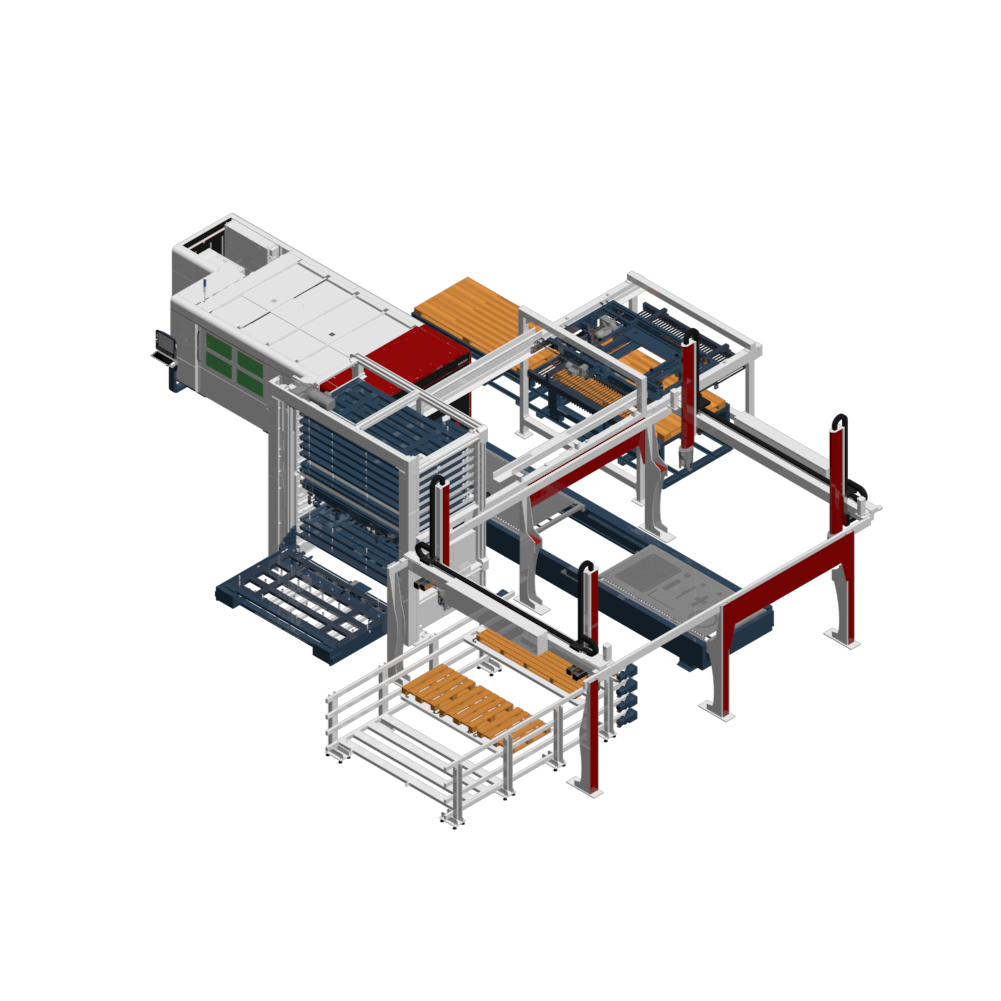

LASER AUTOMATION

Leave your bottom line beaming.

learn more -

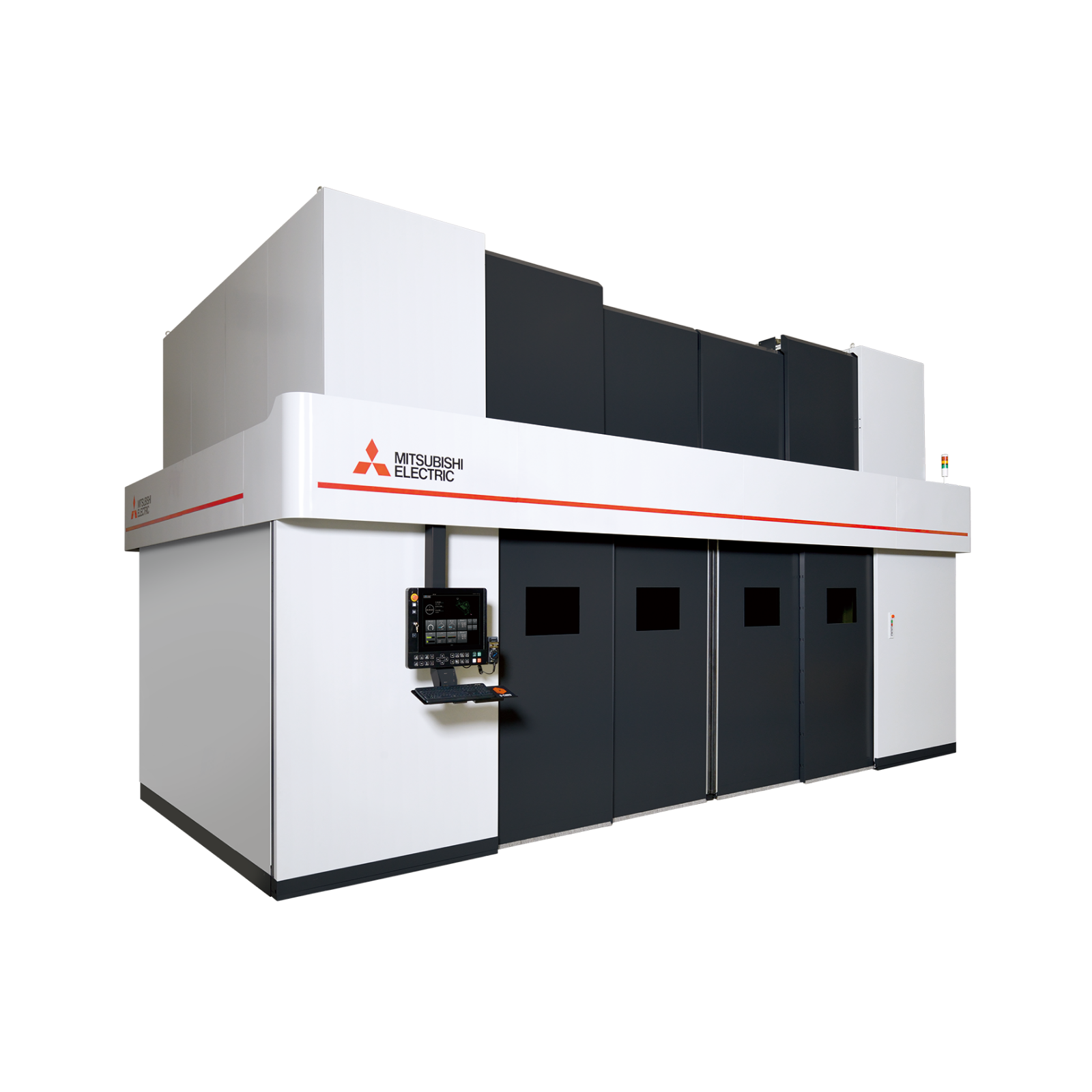

2D CO2 LASERS

Solid construction, advanced programming, and high-speed 2D cutting for thick-cut materials.

learn more -

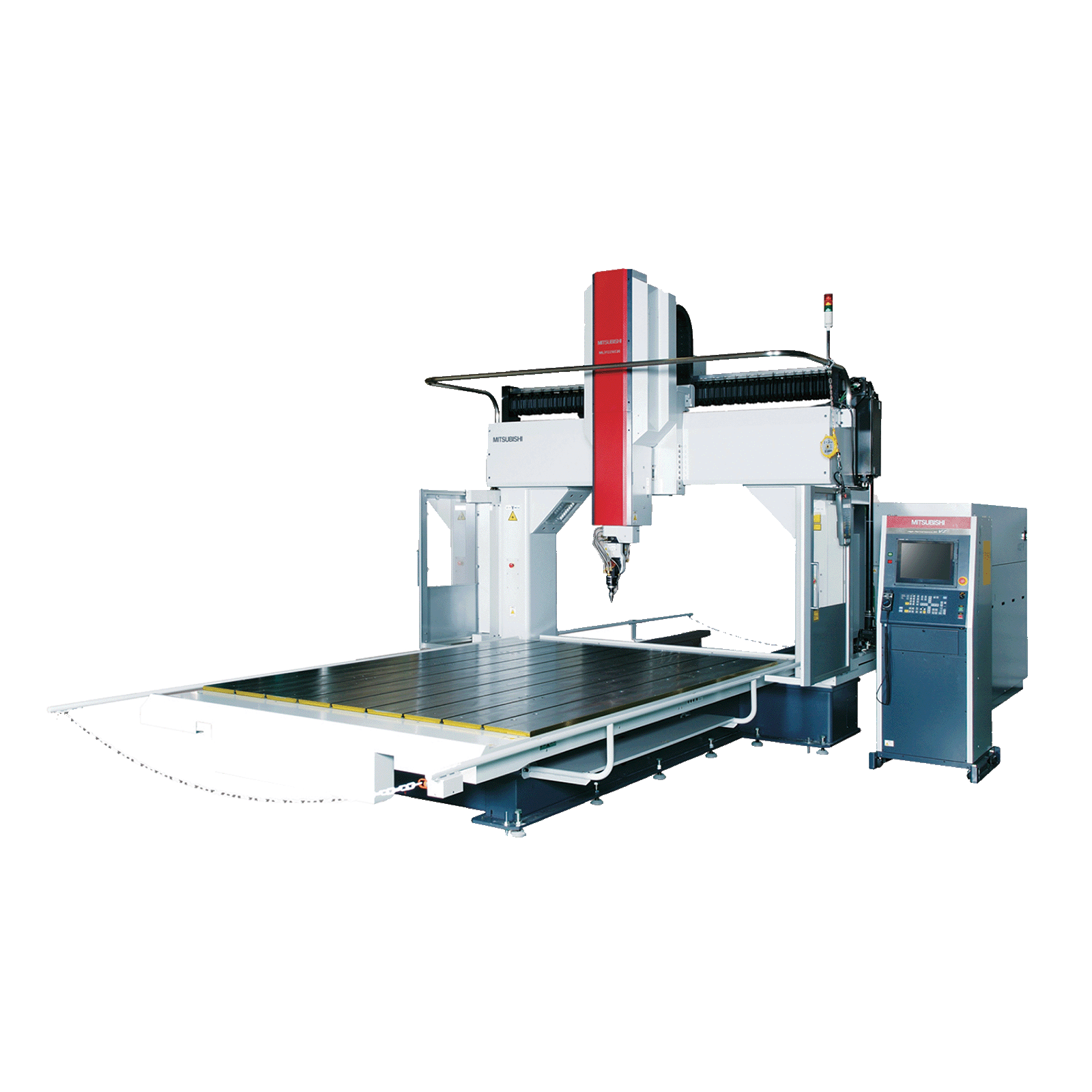

MULTI-AXIS CO2 LASERS

High-performance 3D laser processing for tough materials.

learn more

-

"We’re excited with all of the things that Mitsubishi Laser is bringing to the marketplace because it helps us achieve our goals of being profitable and having sustainable growth."

Si Cha, Olympic Steel's plant manager of the Buford location’s Fabrication Division learn more -

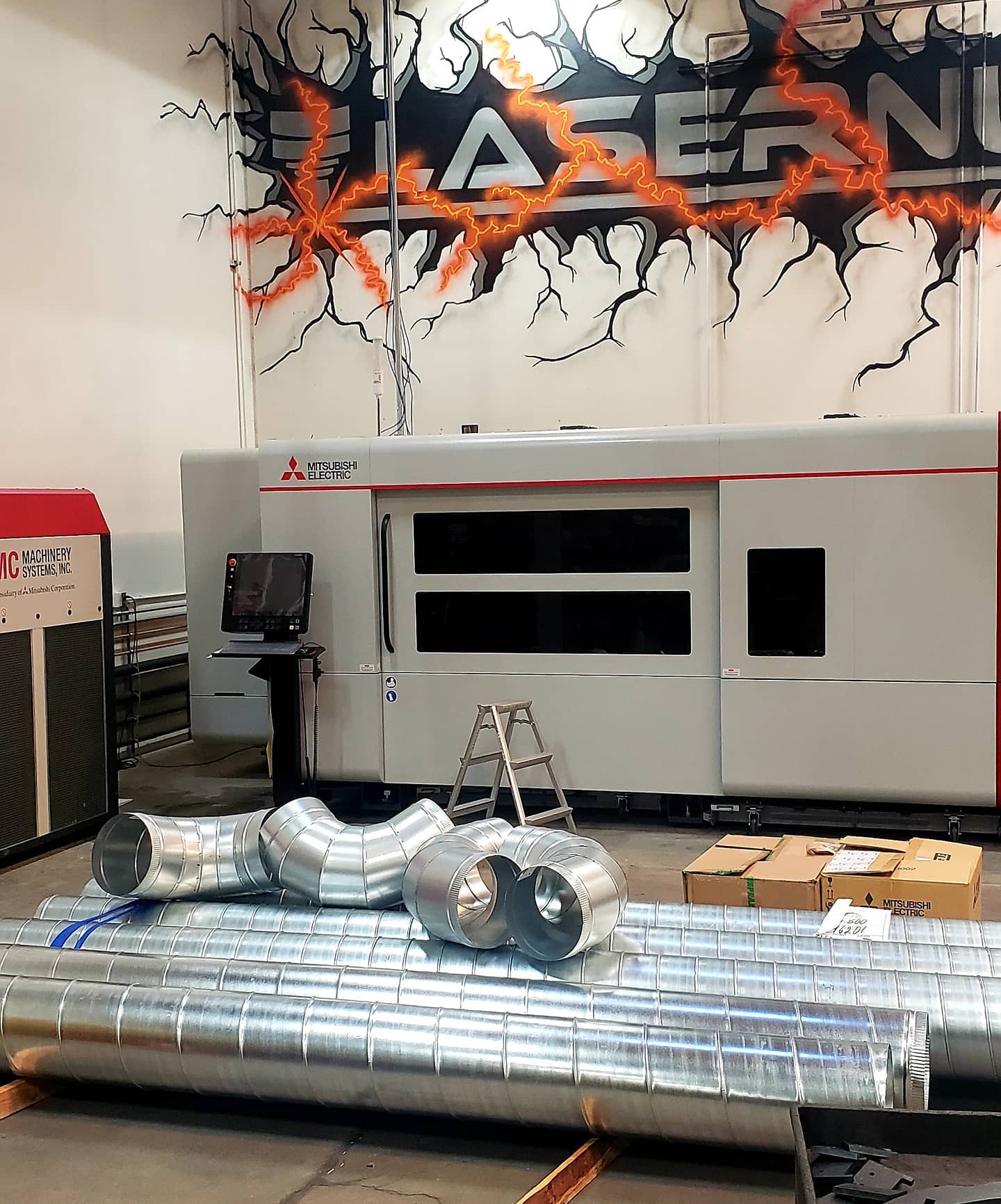

"It is just a mind-blowing, amazing machine. I had never been sold on fiber lasers because of micro-burr and concerns about edge quality, but the GX-F has burr reduction technology that makes burr non-existent."

Cody Waggoner, President of Lasernut learn more