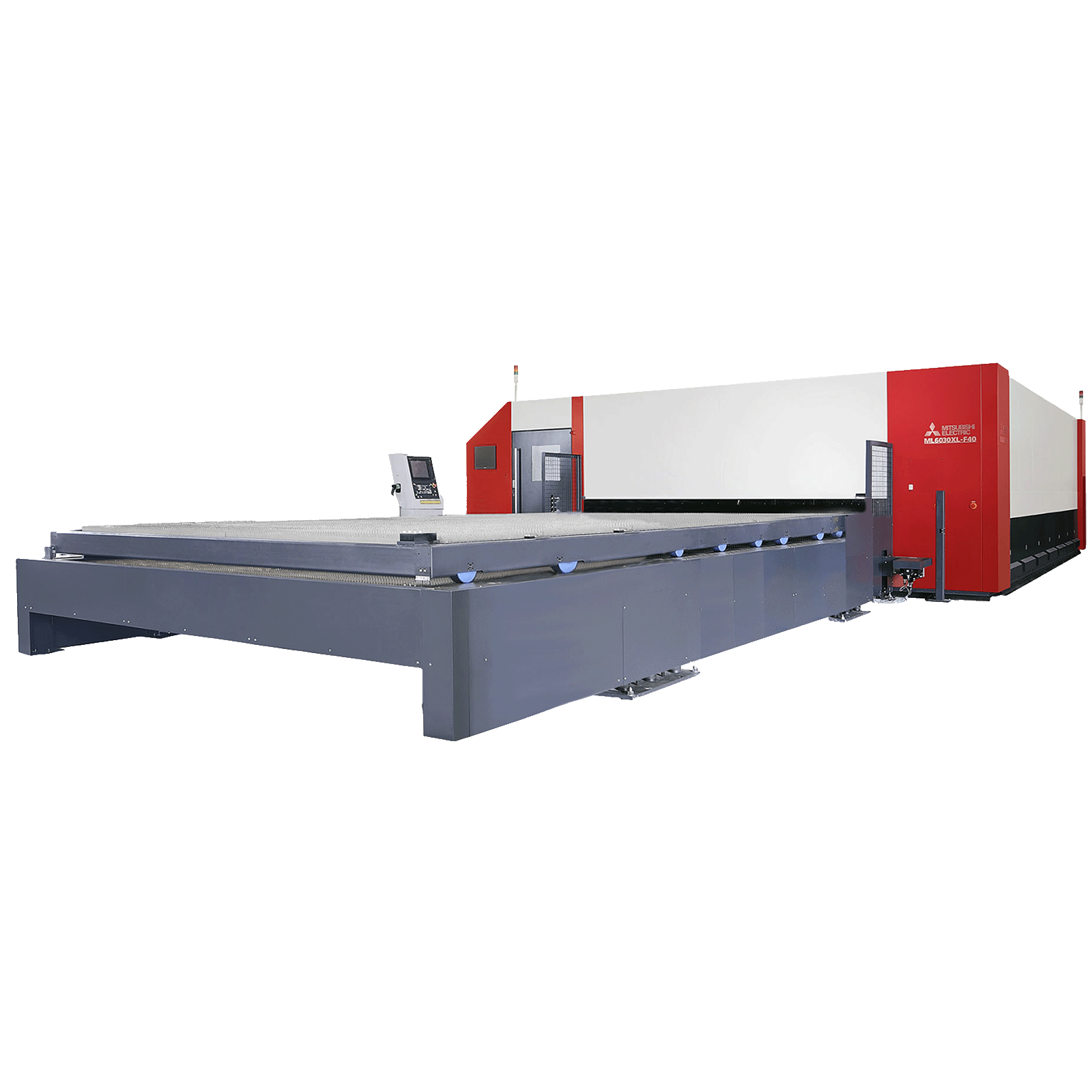

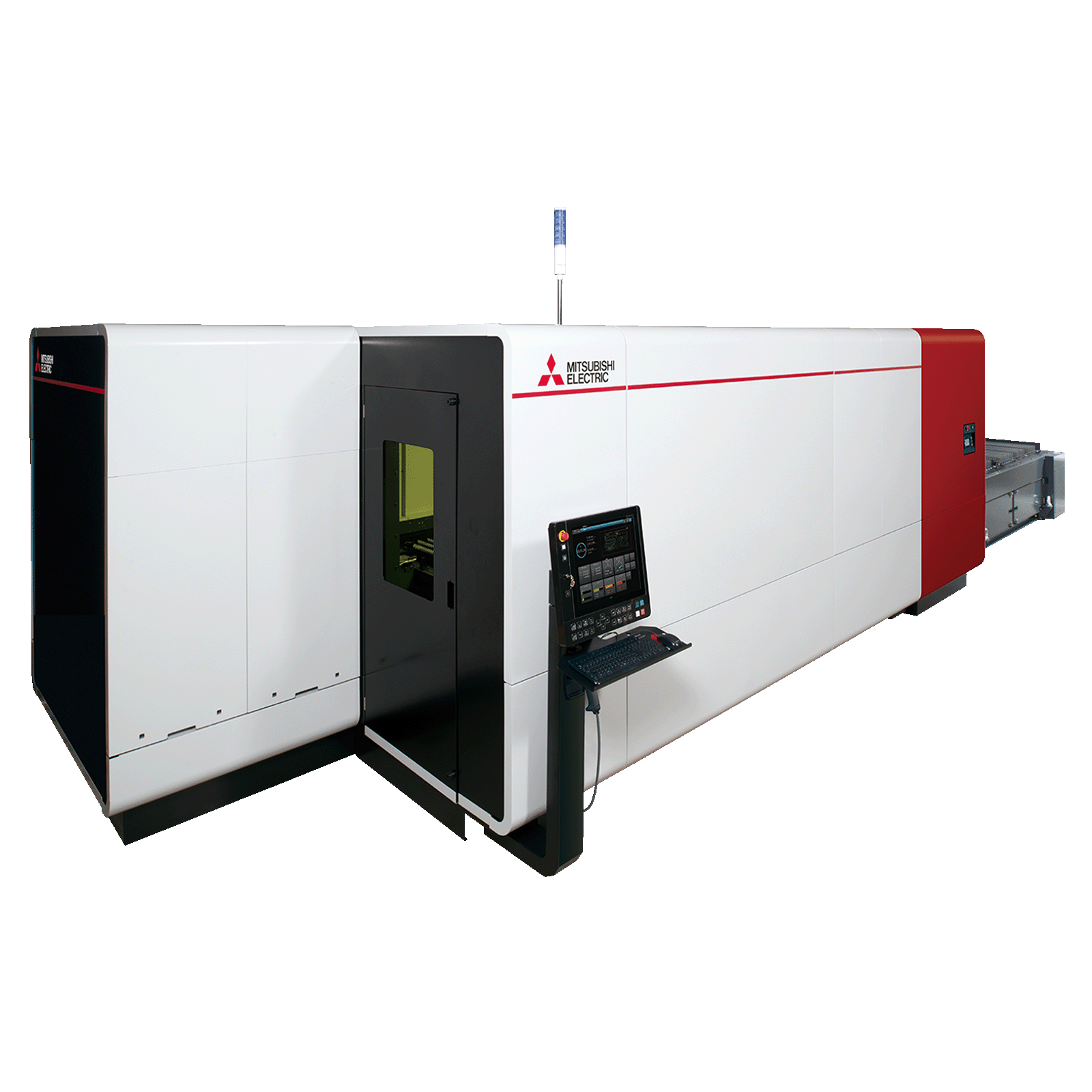

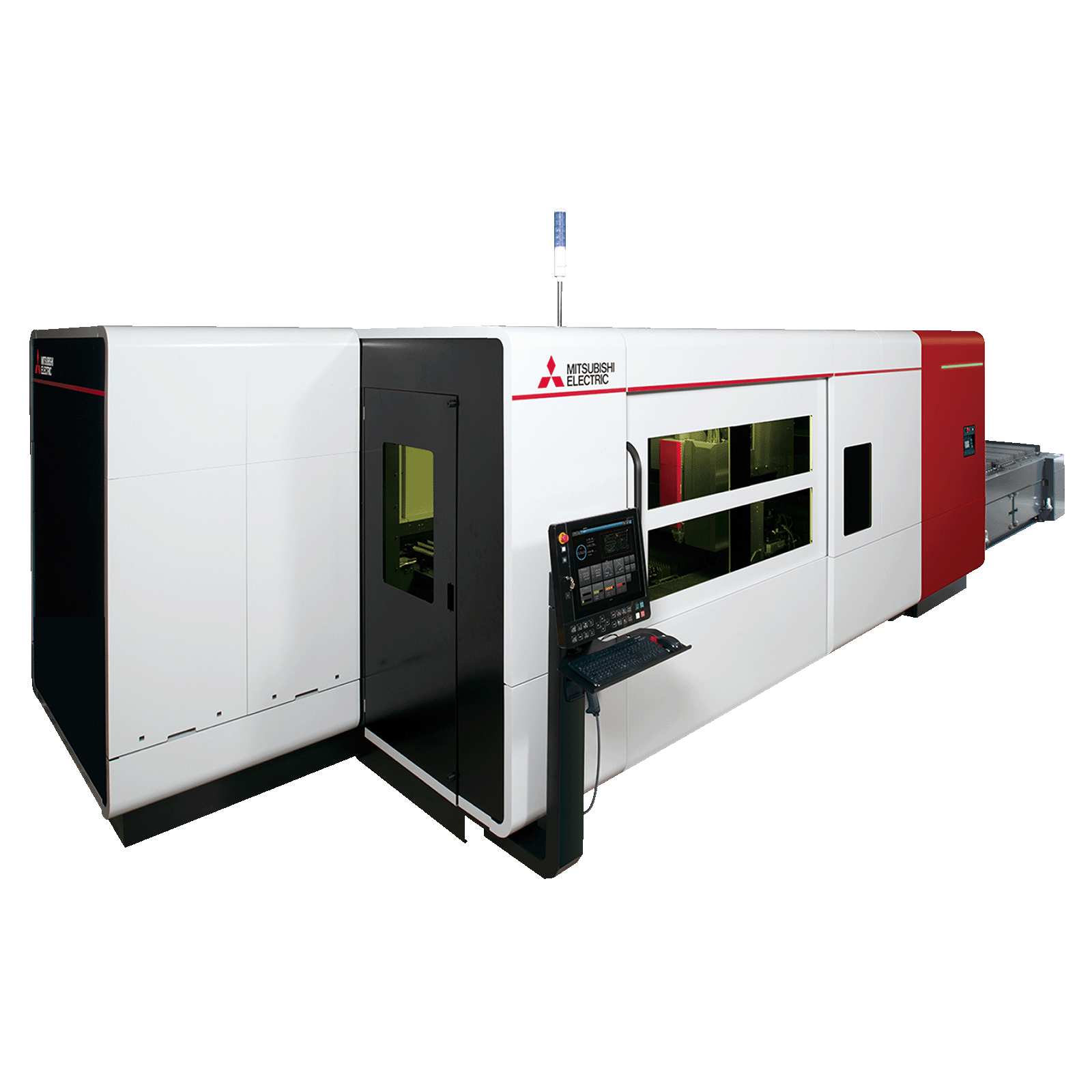

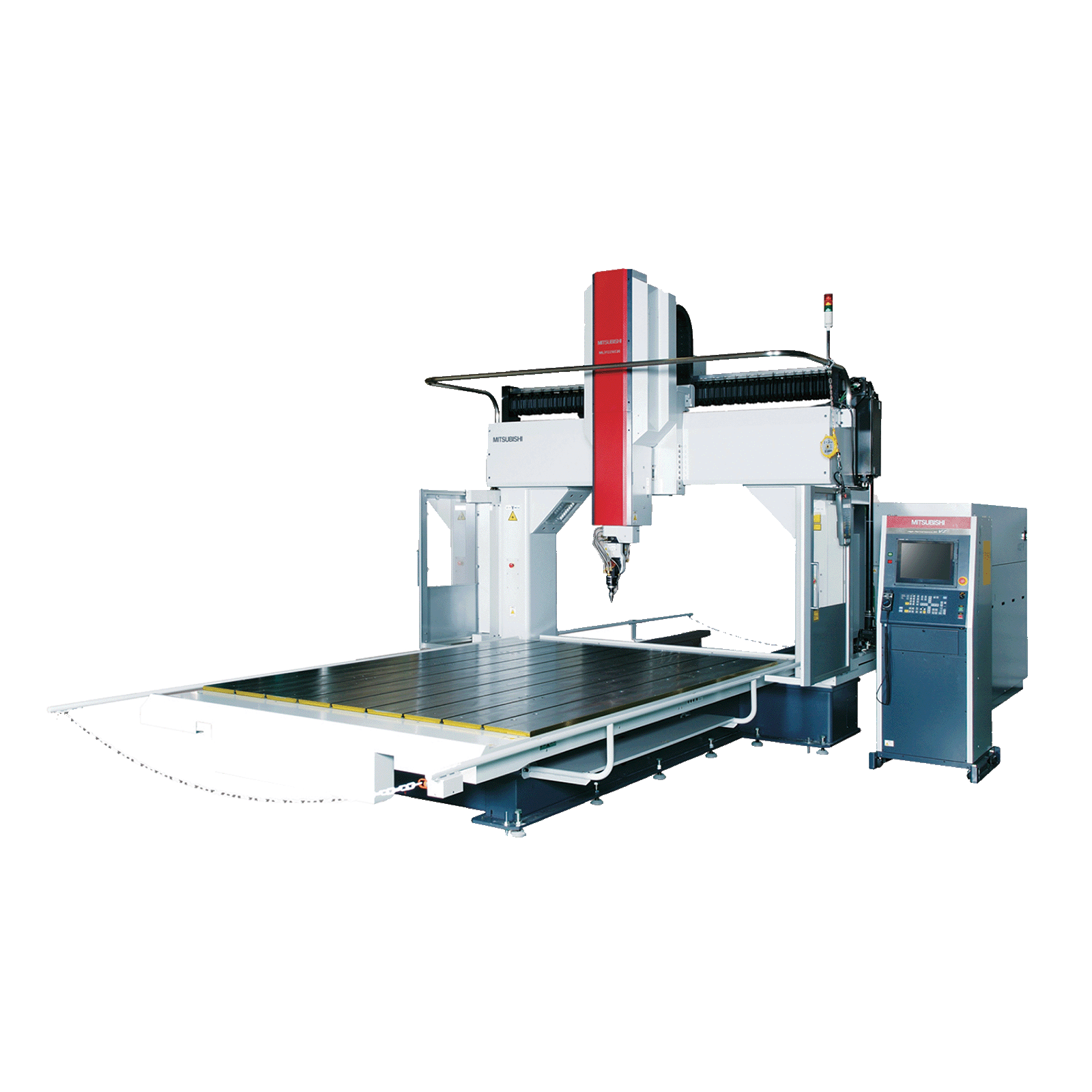

XL-F Series

A large-sized fiber laser that brings fine, high-precision processing to projects of nearly any size.

This large-size laser processing machine gives you the ability to apply the precision cutting prowess of fiber lasers to large, wide, or irregularly shaped workpieces. By eliminating the number of fabrication, bending, and welding processes required for each project, the XL-F produces excellent, strong, seamless, high-quality work in less time—and money—than you’d expect.

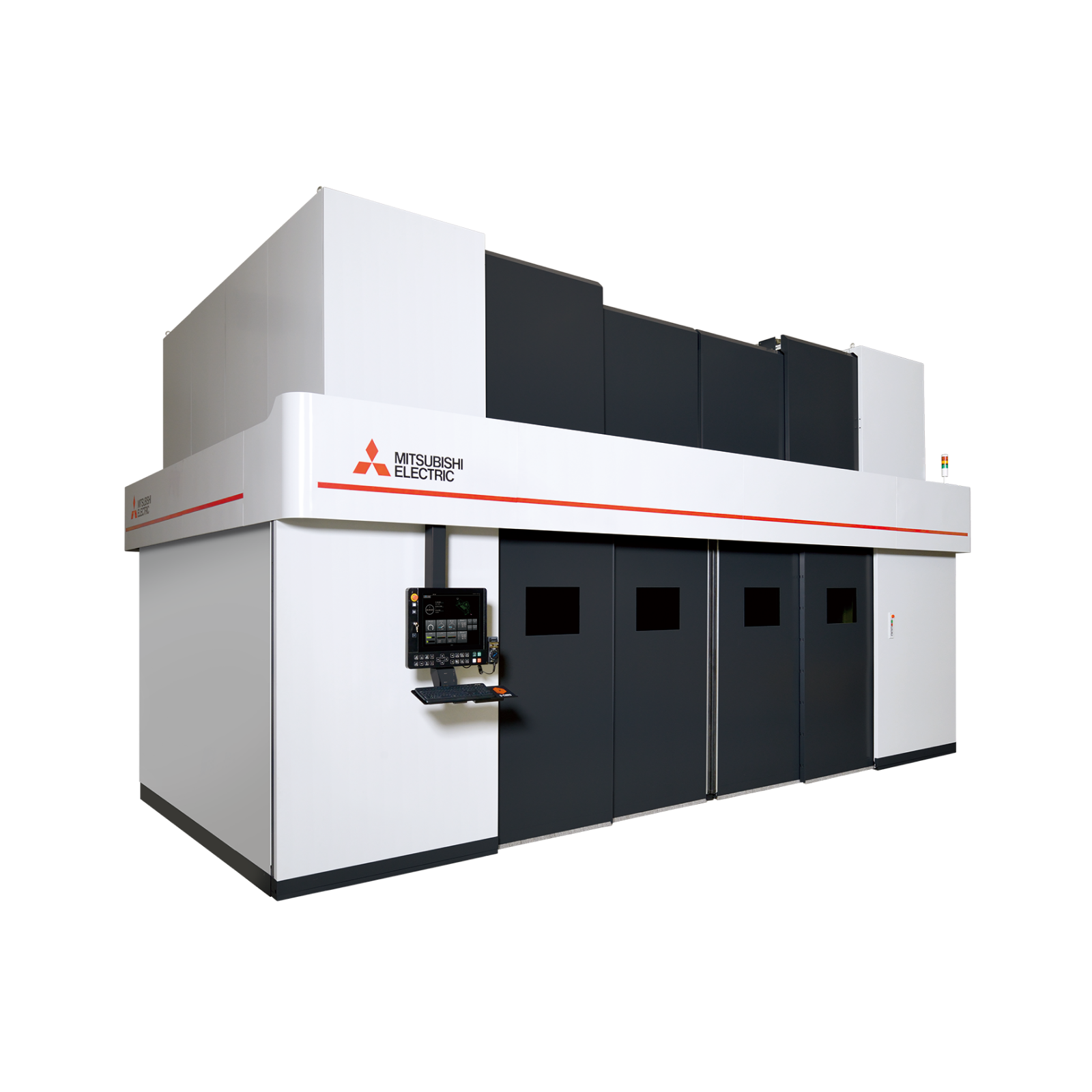

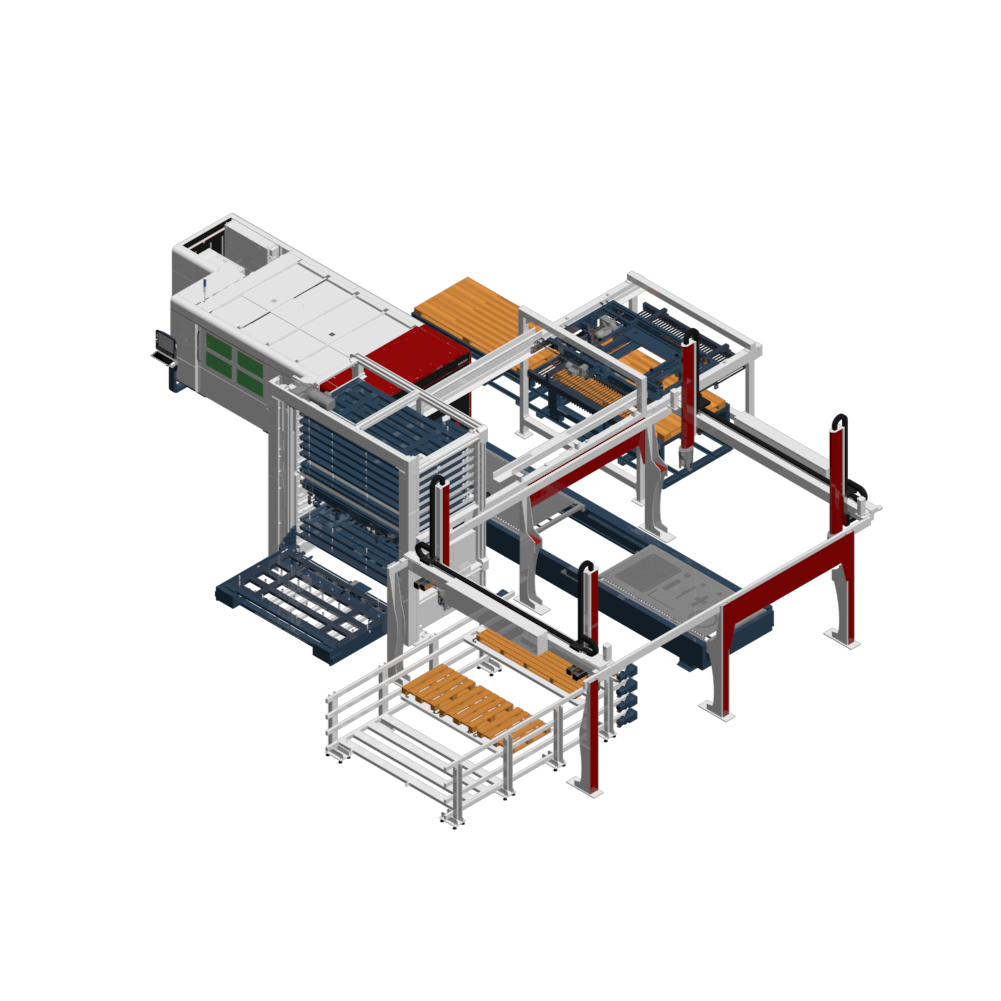

And best of all, the XL-F sports a fully modular design, making it an easy fit with existing or future expansions. Whether you’re in the middle of refitting your entire shop for unmanned production or still exploring your options, this unit’s fully modular design gives you the freedom to pair it with new technologies at your convenience.

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.