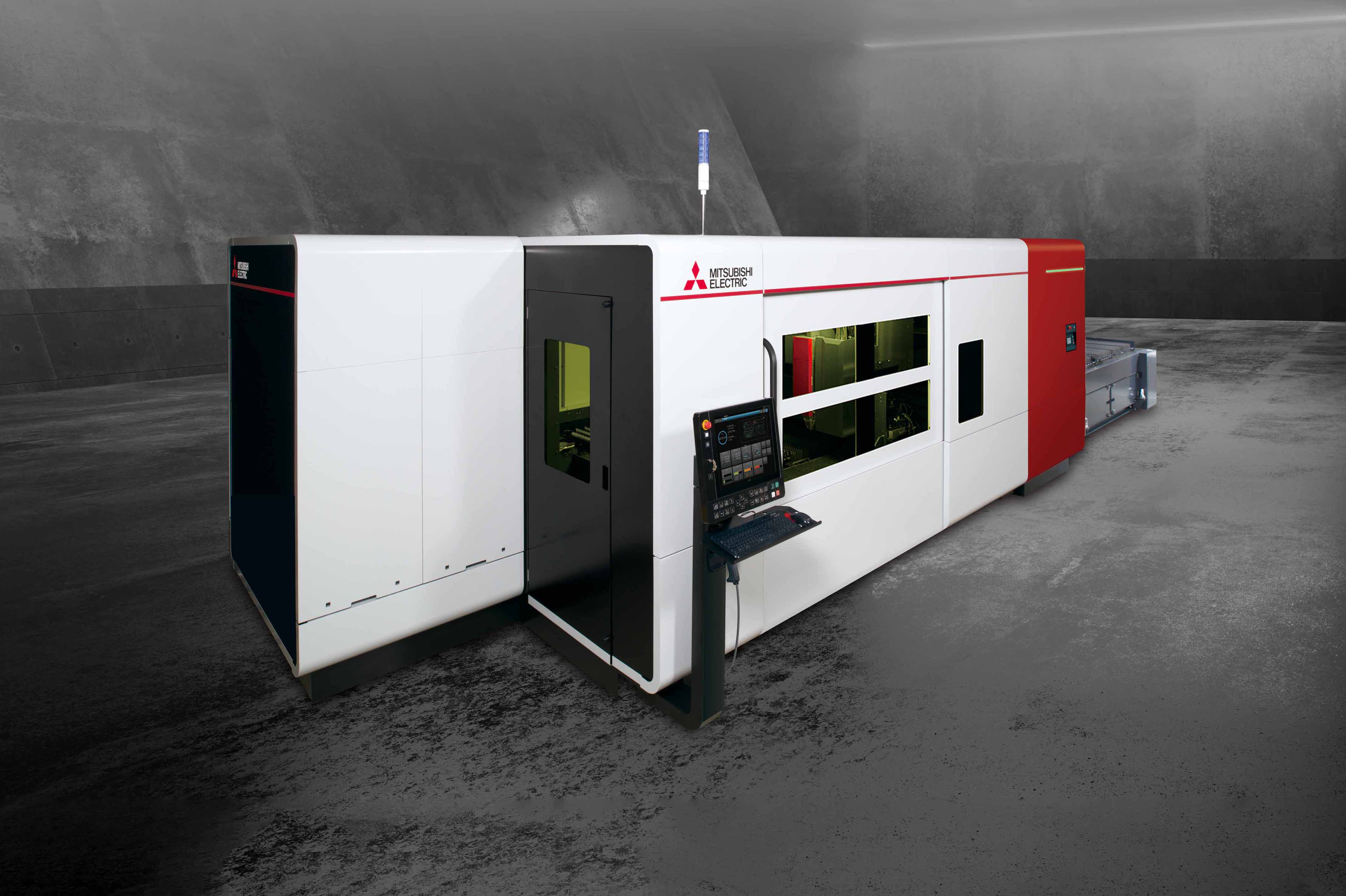

MC Machinery will be showcasing the GX-F ADVANCED fiber laser, a Mitsubishi Diamond BB Series electric press brake, a Mitsubishi Diamond BH Series hybrid press brake and an ADIRA hydraulic press brake in booth 3019 at FABTECH Canada in Toronto June 11-13, where experts from MC Machinery’s Ontario showroom will be available to answer questions and demonstrate the equipment.

The GX-F ADVANCED Fiber Laser

With the latest in artificial intelligence (AI) and gas-reduction technology, the Mitsubishi GX-F ADVANCED Series of two-dimensional fiber lasers delivers more power while using less nitrogen and requiring less operator intervention.

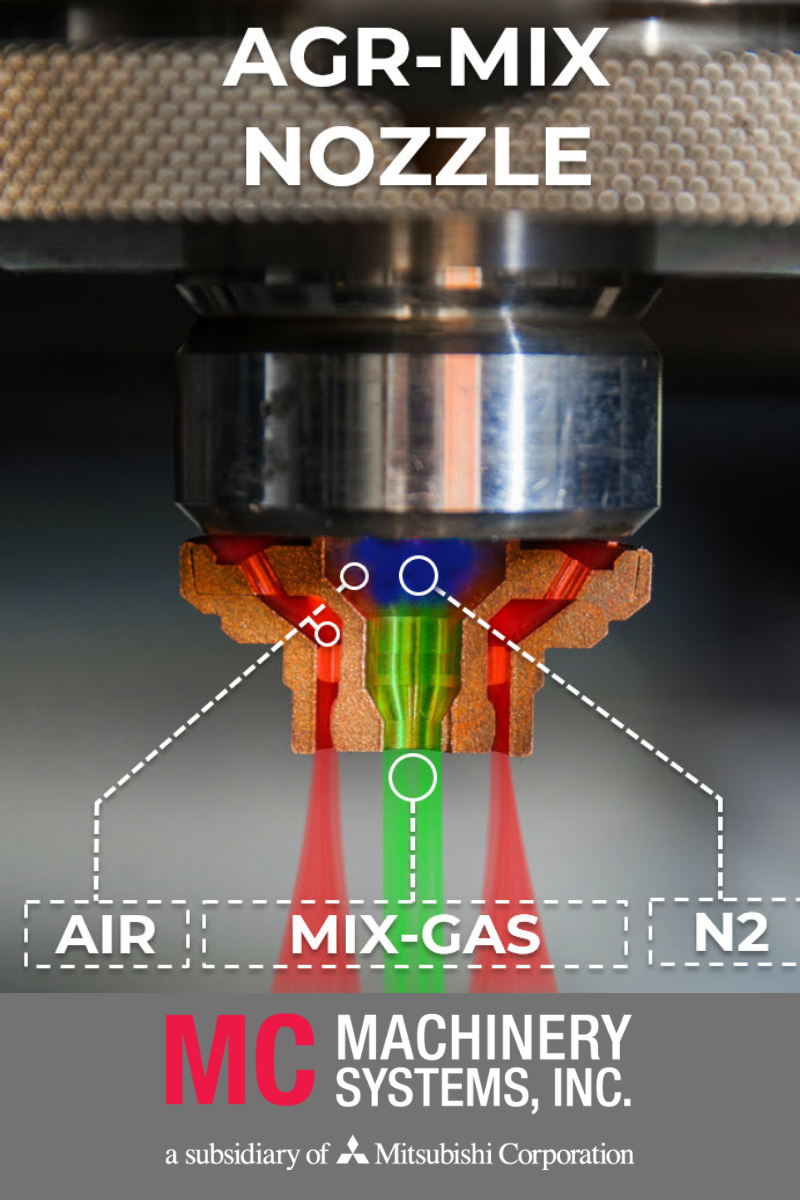

The GX-F ADVANCED Series now includes the Mitsubishi Laser-patented AGR-MIX gas- and burr-reduction nozzle technology, which improves cut quality while reducing gas consumption when cutting mild steel–without the need for external blending tanks or high-pressure oxygen. Building on Mitsubishi Laser’s assist gas reduction (AGR) nozzle technology that saw nitrogen assist gas consumption savings of up to 75 percent, the new AGR-MIX technology adds a further reduction of up to 50 percent without compromising cut quality. By combining low-pressure air with nitrogen within Mitsubishi Laser’s proprietary AGR-MIX nozzle, the blended gas becomes adjustable to suit specific types of material. The result is a cut that eliminates burr on mild steel and reduces costs associated with consumables.

Additionally, intuitive AI technology makes the GX-F ADVANCED Series easy to use for operators of all skill levels—especially valuable because of the ongoing shortage of skilled manufacturing workers. The machine’s augmented reality (AR) capabilities include drop and cut, part rotation and rectangular nesting.

To significantly reduce setup time, the Mitsubishi zoom head delivers speed and flexibility by automatically changing the beam size, shape and focal point for each material, with the ability to process plates with a wide range of thicknesses. Piercing time is reduced by as much as 60 percent, making it possible to pierce a 25-mm-thick mild steel within 0.8 seconds.

Mitsubishi’s proprietary AI technology monitors the cutting process in real time with audio and light sensors, automatically adjusting parameters to optimize cutting performance.

Press Brakes

The Diamond BB Series electric press brake features an AC servo motor and ball screw mechanism for high-speed productivity and repeatability (± 0.001mm). The BB Series is a reliable, cost-efficient solution for accurate repeat-bending work. Equipped with on-board diagnostics capabilities and an intuitive CNC interface, the Diamond BB Series is known for quiet operation, environmental cleanliness and ease of use.

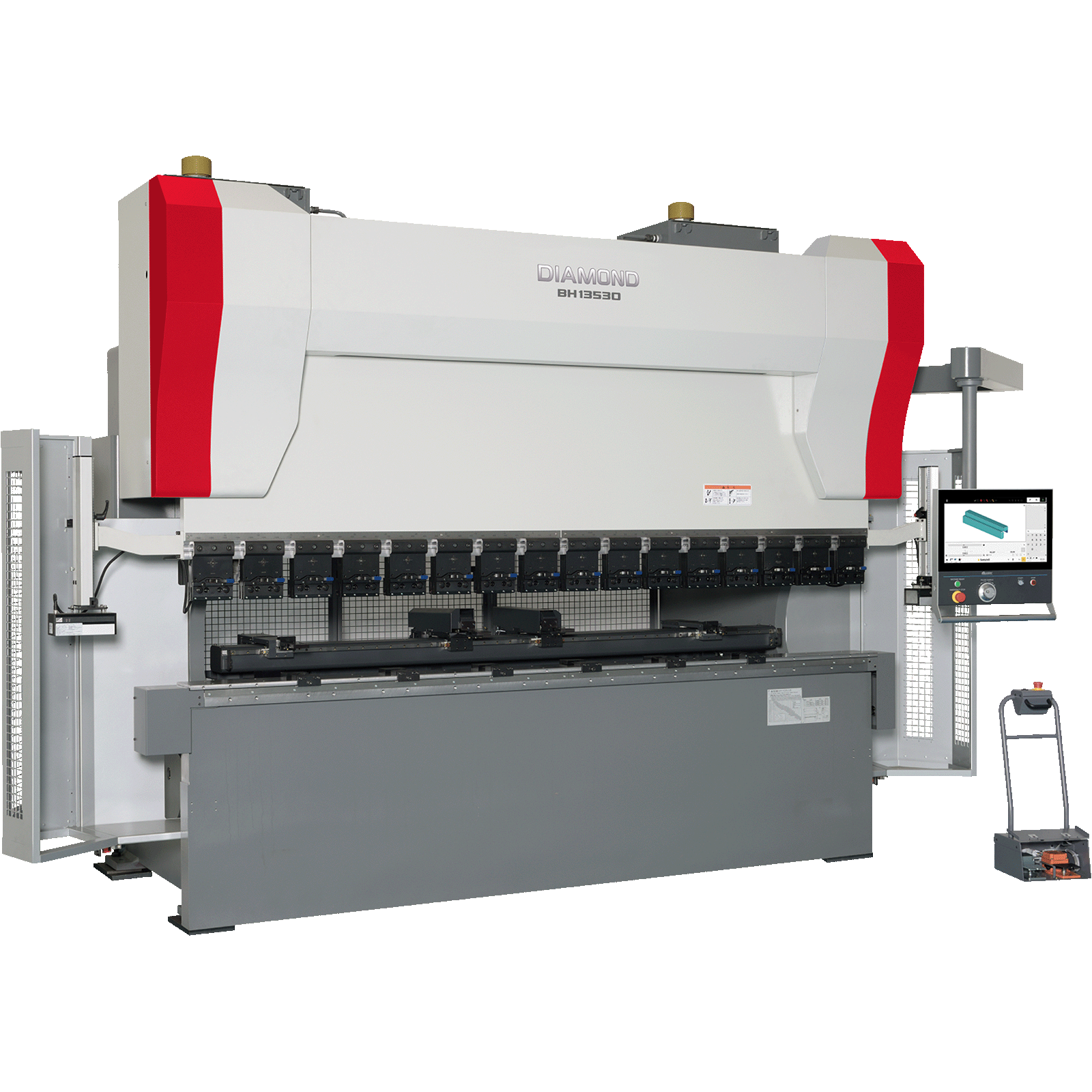

The Diamond BH Series of hybrid press brakes features a patented dual-drive design that combines the best of both hydraulic and electric bending: productivity, precision, high-speed movement, reliability and superior energy savings.

MC Machinery’s ADIRA PA Basic Series hydraulic press brake is flexible and heavy duty with an attractive price-to-performance ratio. Meeting the highest standards for precision bending in a hydraulic press brake, the PA Basic Series can accommodate 135 to 220 metric tons and 3m or 4m lengths with standard crowning. It also features a 15-inch control, front-sheet supports, clamping options and standard four-axis back gauge.