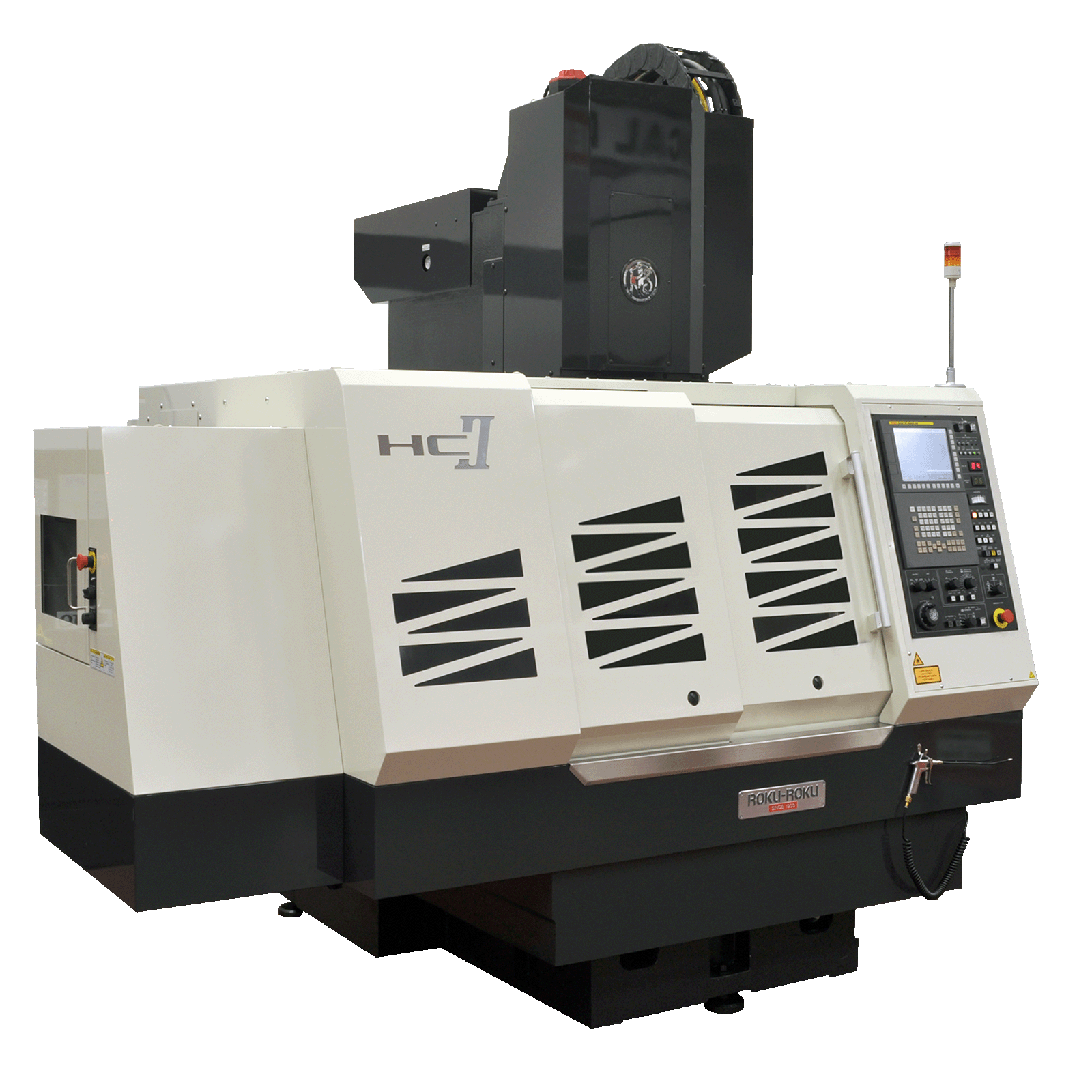

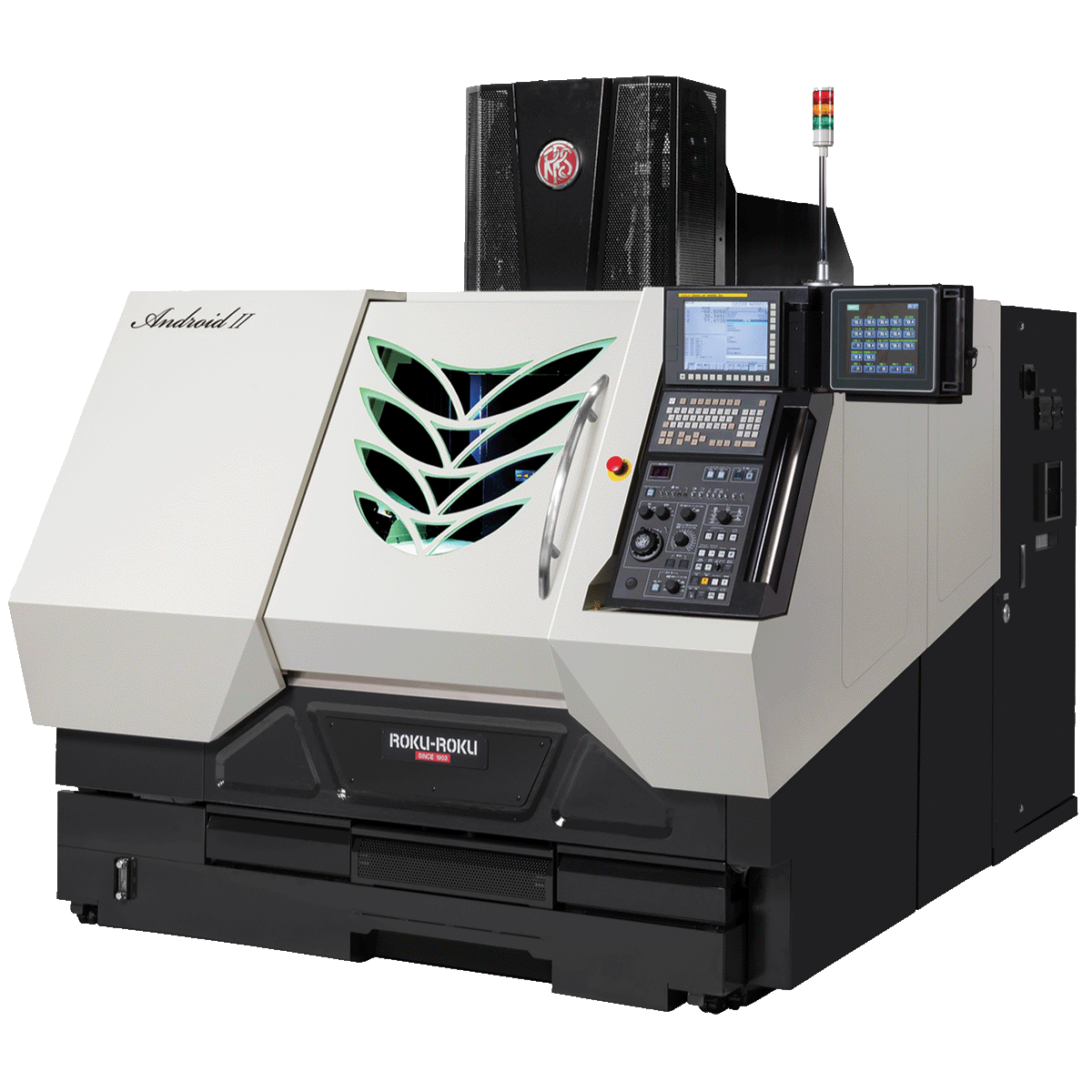

DM-G Series

Our best value for precision 3-axis machining of graphite electrodes, mold/die components, hard milling, and more.

The DM-G series—with the DM-800G and the slightly larger DM-1200G—offers the perfect combination of close-tolerance, high-precision, and intuitive, efficient production.

The 20,000-RPM grease-packed integral motor spindle features a more rigid and accurate tooling system with the flexibility to do fine intricate work. And the 24-position dual swing-arm automatic tool changer will provide better tool-life management and increase the machine’s productivity.

From graphite electrodes preconfigured for dust protection/collection to mold & die work meant for flood or mist machining—for the kind of intricate, high-quality work that keeps your customers coming back for more, the DM-G series is a great addition to your shop floor lineup.

A HIGH-EFFICIENCY WORKHORSE

- When even the smallest details matter, consistency makes a difference. The DM series is all about delivering exceptional cutting performance and repeatability in any situation but with a level of efficiency that will help you run a profitable, high-performance shop.

RELIABLE MICRO-FINE PERFORMANCE

- The DM series comes complete with linear scales and roller guideways that allow these machines to deliver exacting, high-precision performance in close tolerances—where intricate, detailed work matters most.

EASY, INTUITIVE OPERATION

- The Mitsubishi M830S series control now operates from a 15” smartphone-like touchscreen, putting lightning-fast processing power and intuitive, easy-to-learn operation firmly within your worker’s reach.

CAPABILITIES:

- High-performance machine for mold & die applications

- Excels in close-tolerance work

- Better tool-life management and higher machine productivity

- 6x faster processing than the earlier M700V series CNC control, giving your team the power to make short work of intense project loads with up to 270,000-BPM (block per minute) calculation speed on a CNC-dedicated CPU

COMPONENTS:

- Full enclosure

- 20,000-RPM integral motor spindle

- Spindle oil chiller

- 24-position automatic tool changer

- HSK-E40 tool taper

- X, Y, Z axis linear glass scales

- Coolant through spindle prep. (1000 psi)

- Roller pack LM guideways

- Auto oil lube system

- Chip auger

- Air gun

- Water gun

- Oil / coolant separator

- Automatic power shutdown circuit

- 3-stage patrol lamp

- Z axis brake

USER INTERFACE:

- M830 Mitsubishi controller

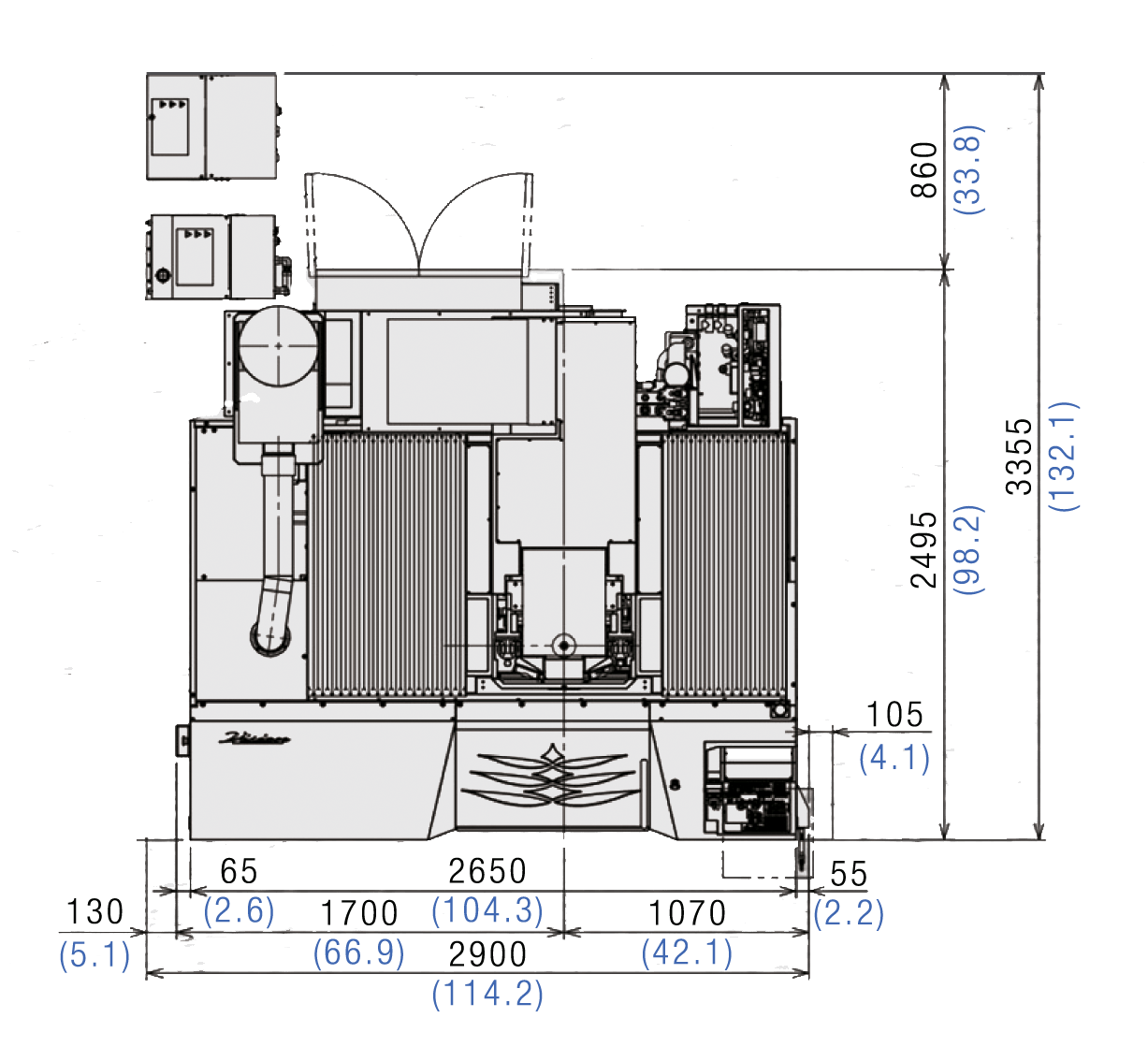

| Model | DM-800G | DM-1200G |

|---|---|---|

| Machine Travels: X x Y x Z in (mm) | 31.5 x 19.7 x 21.3 (800 x 500 x 540) | 47.2 x 23.6 x 26.6 (1,200 x 600 x 675) |

| Spindle Speed | 20,000 | 20,000 |

| Max. tool weight: lb (kg) | 11 (5) | 11 (5) |

| Cutting feedrate: in/min. (mm/min.) | 0.04 – 787 (1 – 20,000) | 0.04 – 787 (1 – 20,000) |

| Table Size X- Y: in (mm) | 35.8 x 19.6 (910 x 500) | 48.0 x 24.4 (1,220 x 620) |

| Max Table Cap: lb (kg) | 1100 (500) | 2,200 (1,000) |

| Spindle HP | 10 / 15 | 10 / 15 |

| Table to Spindle Nose Distance: in (mm) | 5.9 ~ 27.2 (150 ~ 690) | 3.9 ~ 30.5 (100 ~ 775) |

| Arm Type ATC Tool Count Tool Taper | 24 / HSK-E40 | 24 / HSK-E40 |

| Max Tool Dia. w / wo Adj. Tool | 3.1 / 3.9 (80 / 100) | 3.1 / 3.9 (80 / 100) |

| Max Tool Length / Weight in/lb (mm/kg) | 7.9 / 11 (200 / 5) | 7.9 / 11 (200 / 5) |

| X, Y, / Z Rapid Speed in/min. (m/min.) | 1417 / 787 (36 / 20) | 1417 / 787 (36 / 20) |

| Coolant Tank Capacity: gal (L) | 77 (290) | 95 (360) |

| Machine Weight: lb (kg) | 11,700 (5300) | 17,600 (8,000) |

| Mach Dimensions W-D-H: in (mm) | 82.6 x 76.2 x 100.7 (2100 x 1936 x 2557) | 113.4 x 85.8 x 110.2 (2,880 x 2,180 x 2,800) |

| Power Requirements KVA | 25 | 25 |

RELATED SOLUTIONS

-

5-AXIS MACHINING TECHNOLOGY

High-speed, high-precision machines with the power and flexibility to meet any challenge.

learn more -

LINEAR DRIVE TECHNOLOGY

Hyper-accurate machinability for tight tolerances and micro-fine work where the details really matter.

learn more -

HIGH SPEED MACHINING

Top-of-the-line machinery with added cooling power for consistent performance on mission-critical tasks.

learn more -

GRAPHITE MANUFACTURING

Multiple solutions and expertise in making graphite electrodes.

learn more -

MILLING AUTOMATION

Multiple solutions and expertise in making graphite electrodes.

learn more

-

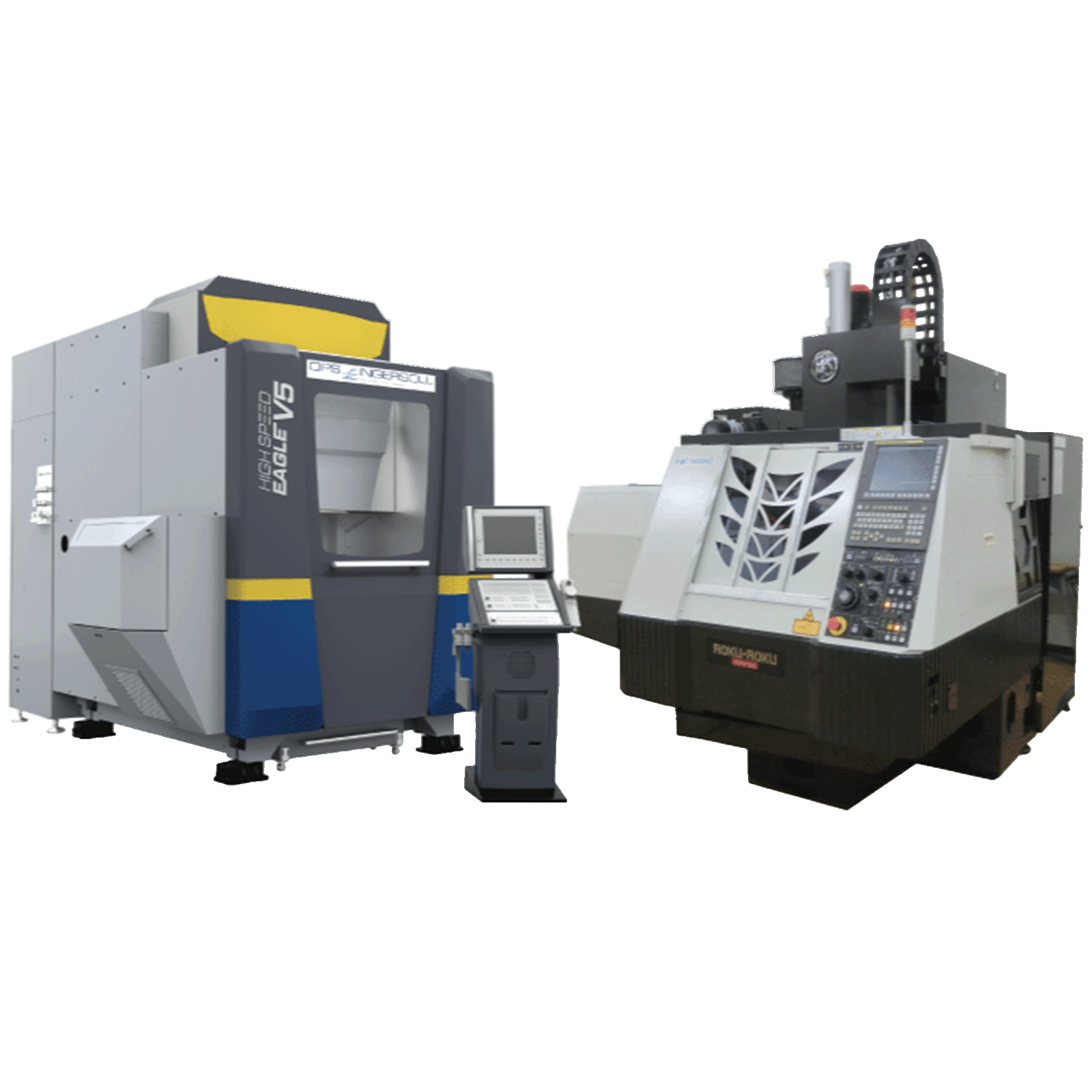

"Not only does the 5-axis capability of the OPS Ingersoll Eagle V5 milling machine enable us to burn parts with less physical electrodes, it also has a robotic tool changer so we can focus more during the day on things that need constant attention."

Brad McDowell, Quality Tool & Die president Read case study -

"The OPS Ingersoll 5-axis milling machines are fast, accurate, easy to operate and have a small footprint."

Bill Yakle, Owner of Aisling Industries learn more -

"The Eagle 800 has burn technology that gives us a competitive advantage because it takes about half the time to burn and uses fewer electrodes, which saves both time and money. Our goal is to run it all day and all weekend. I like that we also are cutting down on our carbon footprint by using fewer graphite electrodes and less copper wire than before."

Steve Michon, President at Zero Tolerance view case study -

"We used to struggle with tool deflection on deep cuts. Now we’re able to tip that up in a five axis and actually hit on the bottom of the flute. And we’re not getting that tool push anymore. Electrodes are so, so much more accurate."

Chad Kearns, Quality Tool & Die vice president Read case study -

"Our biggest supply chain issue is labor, but we have been able to achieve lights-out operation by adding the MC Machinery equipment. We have kept costs down while improving accuracy and doing more with the same number of employees."

Todd Doerfert, Operations Manager at Mantz Automation learn more -

"The kinematics of the Roku-Roku VMCs allow us to run faster feed rates and not sacrifice surface finish or accuracy. The machines are efficient in terms of increased cutter life, reliable Fanuc control and overall machine stability. We can run longer intervals on downstream inspection on parts that the Roku-Rokus machined."

John TerBeek, Co-Owner at TerBeek Molding & Tool view case study