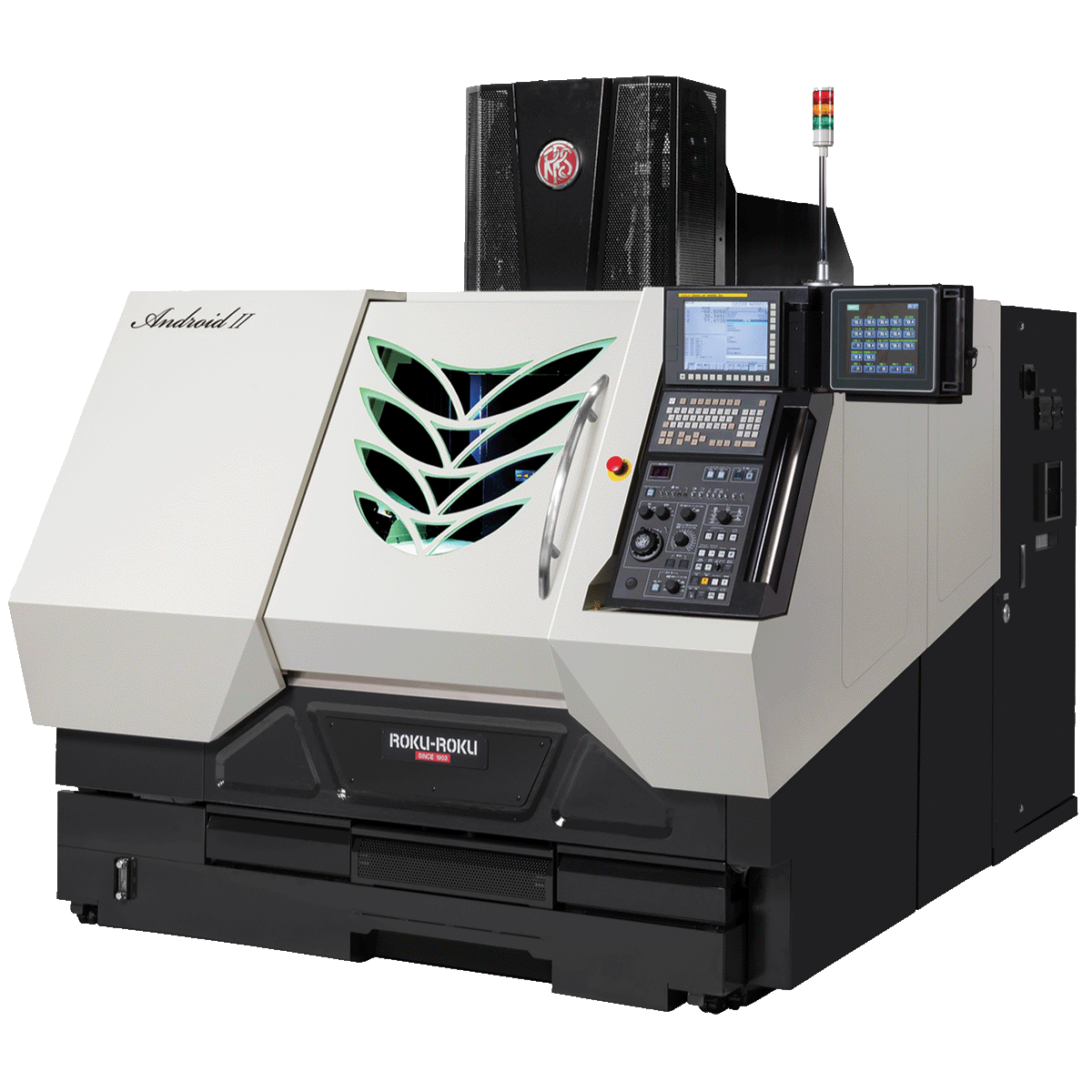

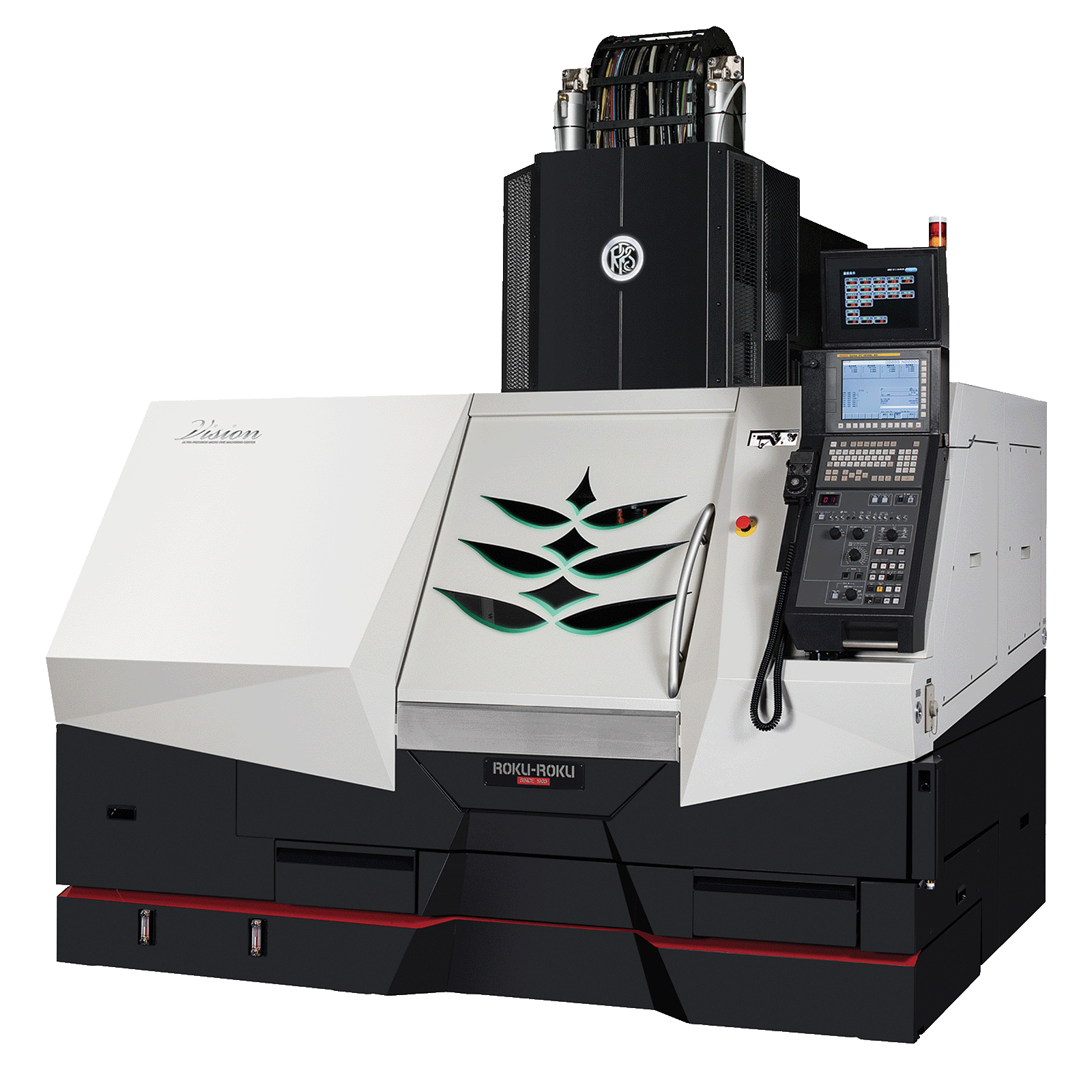

VISION 300

Linear motor technology – available in either the standard 20 HP-30,000 rpm spindle or the 60,000 rpm option.

For years, tool, die, and mold makers have relied on EDM to produce tools in hardened steels that were difficult or impossible to machine. While EDM is certainly up to the job, it adds an extra step to the metal cutting process. And with the constant pressure you’re under to cut lead times and streamline processes, we thought that was just one step too many.

To boost productivity on high-precision, high-quality jobs, you need a tool that knows how to deliver accuracy, quality, precision, and speed—all at the same time.

The Vision 300 is a machining center designed from the ground up for extremely precise, hard-steel machining at high spindle speeds and high traverse rates on large workpieces.

BRINGS BIG PRODUCTIVITY TO BIG PROJECTS

- In the past, large workpieces used to present large problems for shop operators. The Vision 300 incorporates high-speed spindles (up to 30,000 RPM); extremely accurate, horizontally opposed, linear motor servo drive systems; and high-speed machine controllers into a larger, higher-powered (20 HP) model.

RELIABLE BY DESIGN

- The Vision 300’s heat-symmetric basic frame structure with a high-grade cast iron base ensures twist rigidity against spindle head motion. Its structure guarantees a reduction in thermal displacement, leading to a balance of high rigidity and a reduced weight. The two horizontally opposed, flat linear motors equipped with powerful magnets ensure clearance in the side-ways, canceling out any attraction forces.

The system’s dual-layer cooling system combines direct forced-oil cooling with a wide-range jacket to separate the spindle head from the casting. Leading to complete heat isolation, the double cooling system positioned between the heat-generating coils is matched by an in-line oil chiller unit to ensure complete control of the coolant temperature. Hot air will never collect at the spindle thanks to the Vision 300’s centralized exhaust and outside airflow system.

FINE WORK AT ANY SKILL LEVEL

- Coupled with the Fanuc 31i-B5 CNC controller, the Vision 300 is an exceptionally well-built machine tool that can be operated by users of nearly any skill level. With three (3) preprogrammed machining modes available, your workers can produce great results with unsurpassed speed and accuracy—even in the most complex 3D contours.

COMPONENTS:

- X, Y, and Z axis, horizontally opposed, linear motor drive system

- Special precision roller-type linear motion ways

- Active HIS (Heat Isolation System)

- Advanced M-Kit (visual machine behavior)

- Super TMS (Tool Measurement System)

- ASC (Auto Saturation Check) function

- Auto lubrication

- Full enclosure

- Special way covers reduce motion resistance

- 30,000-RPM, 20-HP integral motor spindle

- Spindle chiller

- M&H Super TMS (Tool Measuring System)

- 68-gallon (260L) coolant tank

- 20-position automatic tool changer

- X, Y, and Z axis (2 NANO meter) linear scales

- Mist collector

- Oil temperature control for coolant

- Tool tightening block

- Automatic power shutdown circuit

- Work washer gun

- Air purge

- 4” color monitor

- 2-stage patrol lamp (yellow, red)

- Manual handle feed

- One machine lamp (LED)

- Tool box

- Maintenance kit

- Leveling bolts and pads

USER INTERFACE:

Fanuc 31i-B5 Control

- Super PC III function (3-mode operation)

- AI Contour Control II, high-speed processing, nano smoothing, and look-ahead block expansion

- Editable data server with 2GB program storage (flash card type)

- Ethernet with TCP/IP protocol & RS232 communications

- 320 meters memory (128KB)

- Custom macro B

- Parts count & run hour display

- Inch/metric switching

- Helical interpolation

- Program restart

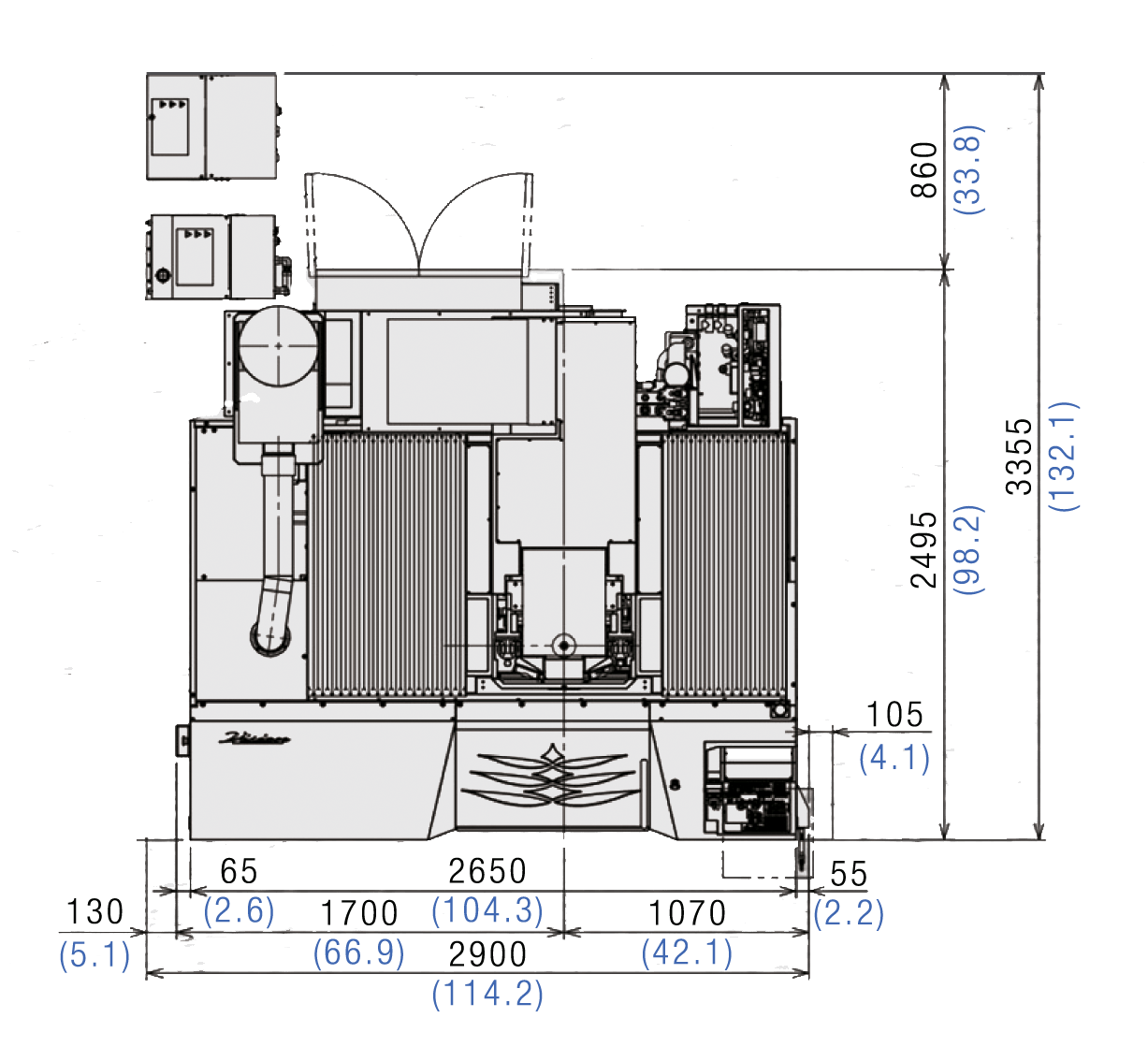

| Model | VISION 300 |

|---|---|

| Machine Travels: X x Y x Z in (mm) | 25.6 x 21.6 x 11.8 (650 x 550 x 300) |

| Spindle Speed | 200 ~ 30,000 RPM |

| Table Size X- Y: in (mm) | 29.5 X 21.6 (750 X 550) |

| Spindle HP | 20.0 |

| Spindle Lubrication | Oil Mist |

| Spindle Taper | 1/10 taper (Two-plane constraint) |

| Tool Shank | HSK-E40 |

| Tool Changer Size | 20 Position Standard |

| Positioning Accuracy/Repeatability: in (μm) | ±0.000039/±0.0000079 (±1.0/±0.2) Full Stroke |

| Table to Spindle Nose Distance: in (mm) | 5.9 ~ 17.7 (150 ~ 450) |

| Max. Workpiece Weight: lb (kg) | 660 (300) |

| Table Height from Floor: in (mm) | 33.5 (850) |

| Oil Mist Collector | Standard |

| Linear Scales X, Y, Z – axes | Heidenhain 0.002µm (2nm) Standard |

| Rapid Traverse Speed: in/min. (m/min.) | 590 (15) |

| Cutting Speed: in/min. (m/min.) | 390 (10) |

| Dust Collection System | NA |

| Coolant Tank Capacity: gal (L) | 68 (260) |

| Machine Weight: lb (kg) | 19,180 (8,700) |

| Machine Height: in (mm) | 115.0 (2,920) |

| Required Floor Space [Mach. Unit]: in (mm) | 114.0 x 132.0 (2,900 x 3,355) |

| Control Unit | Fanuc 31i-B5 Super High-Speed Processor and Al Contour Control II and Super PC X Function |

| Power Requirements KVA | 200 ~ 220V 36.0 kVA |

| Air Supply | 9 cu.ft./min @ 72 psi |

RELATED SOLUTIONS

-

5-AXIS MACHINING TECHNOLOGY

High-speed, high-precision machines with the power and flexibility to meet any challenge.

learn more -

LINEAR DRIVE TECHNOLOGY

Hyper-accurate machinability for tight tolerances and micro-fine work where the details really matter.

learn more -

HIGH SPEED MACHINING

Top-of-the-line machinery with added cooling power for consistent performance on mission-critical tasks.

learn more -

GRAPHITE MANUFACTURING

Multiple solutions and expertise in making graphite electrodes.

learn more -

MILLING AUTOMATION

Multiple solutions and expertise in making graphite electrodes.

learn more

-

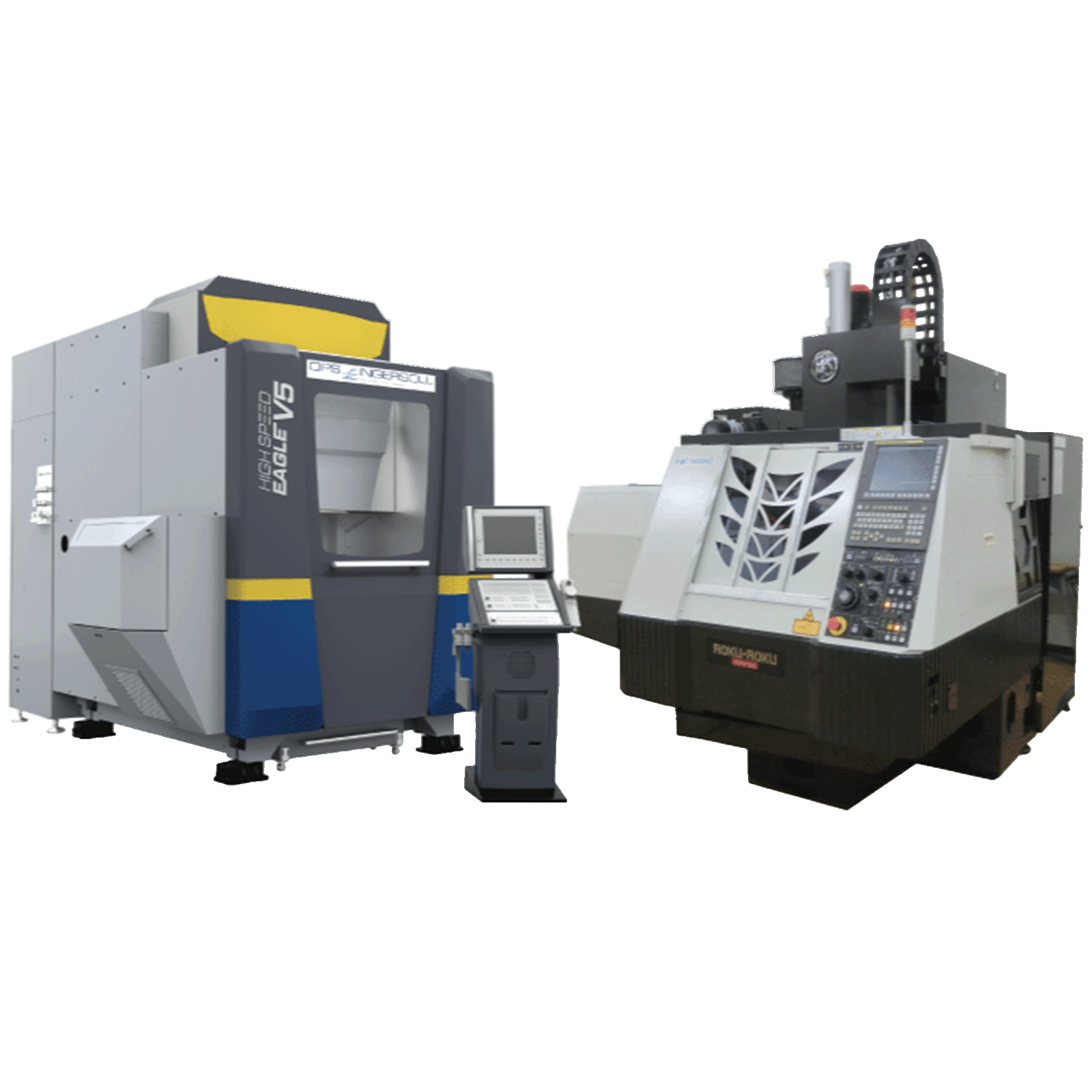

"Not only does the 5-axis capability of the OPS Ingersoll Eagle V5 milling machine enable us to burn parts with less physical electrodes, it also has a robotic tool changer so we can focus more during the day on things that need constant attention."

Brad McDowell, Quality Tool & Die president Read case study -

"The OPS Ingersoll 5-axis milling machines are fast, accurate, easy to operate and have a small footprint."

Bill Yakle, Owner of Aisling Industries learn more -

"The Eagle 800 has burn technology that gives us a competitive advantage because it takes about half the time to burn and uses fewer electrodes, which saves both time and money. Our goal is to run it all day and all weekend. I like that we also are cutting down on our carbon footprint by using fewer graphite electrodes and less copper wire than before."

Steve Michon, President at Zero Tolerance view case study -

"We used to struggle with tool deflection on deep cuts. Now we’re able to tip that up in a five axis and actually hit on the bottom of the flute. And we’re not getting that tool push anymore. Electrodes are so, so much more accurate."

Chad Kearns, Quality Tool & Die vice president Read case study -

"Our biggest supply chain issue is labor, but we have been able to achieve lights-out operation by adding the MC Machinery equipment. We have kept costs down while improving accuracy and doing more with the same number of employees."

Todd Doerfert, Operations Manager at Mantz Automation learn more -

"The kinematics of the Roku-Roku VMCs allow us to run faster feed rates and not sacrifice surface finish or accuracy. The machines are efficient in terms of increased cutter life, reliable Fanuc control and overall machine stability. We can run longer intervals on downstream inspection on parts that the Roku-Rokus machined."

John TerBeek, Co-Owner at TerBeek Molding & Tool view case study