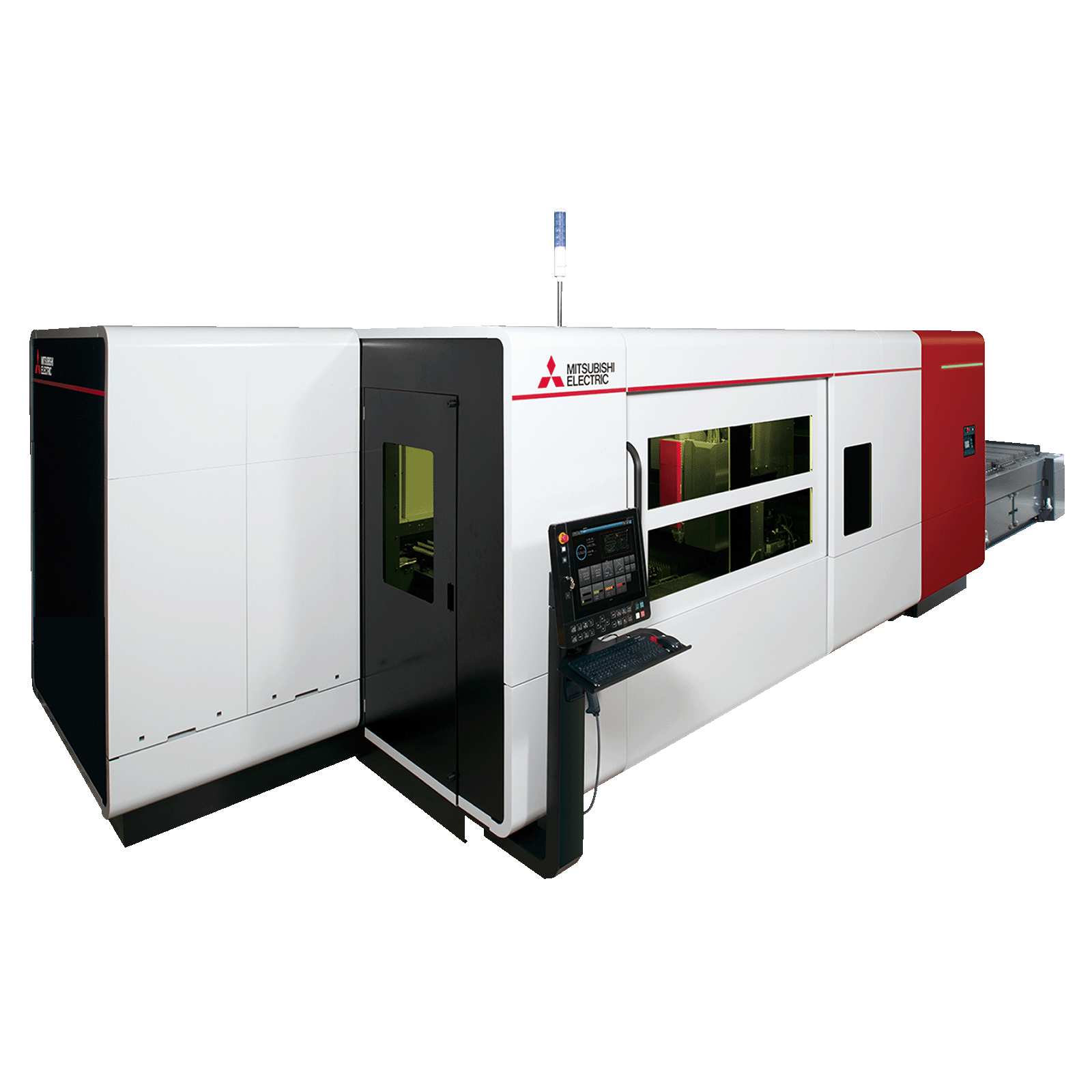

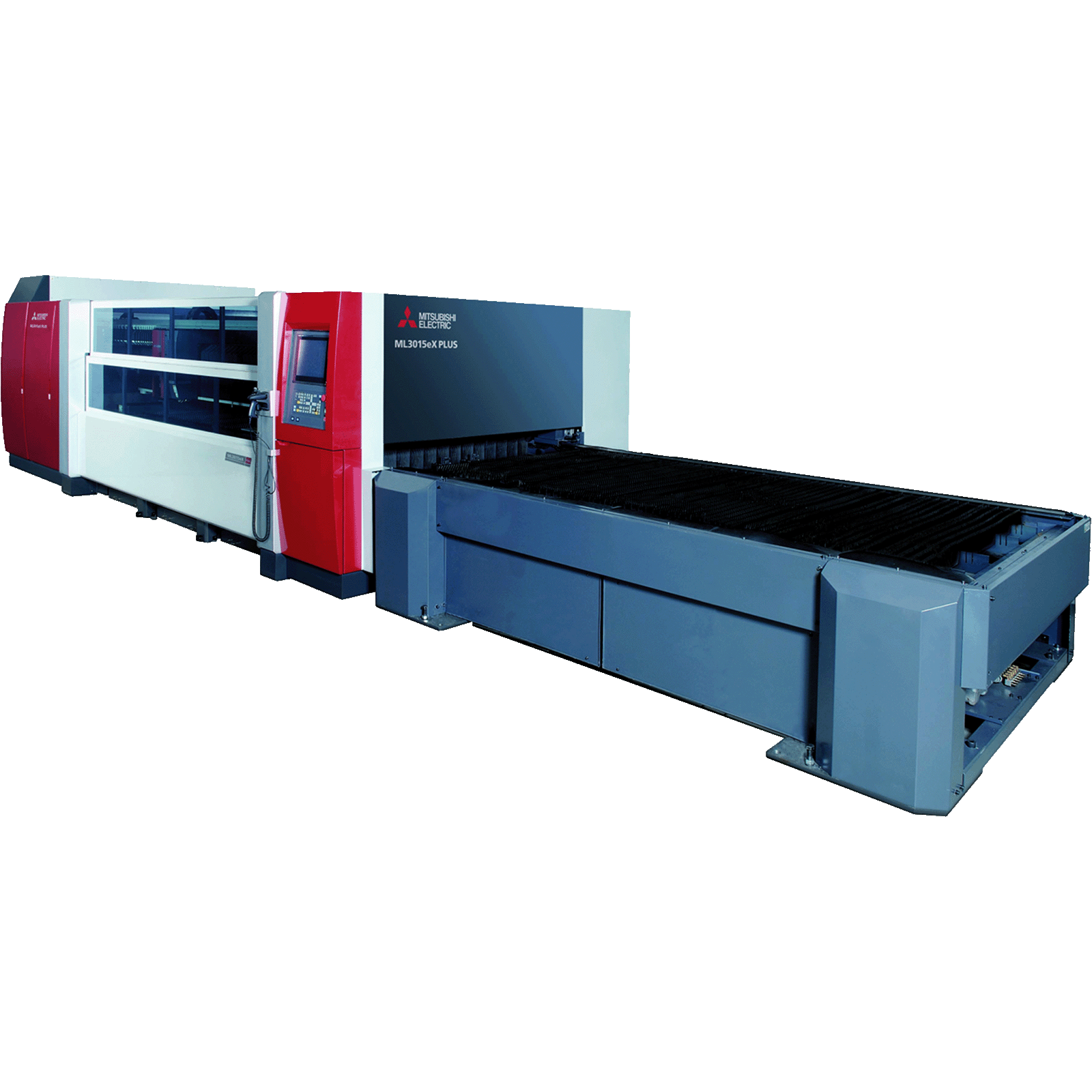

eX Plus Series

The ultimate in high–performance laser machining, built for simple, cost-effective operation.

Today’s competitive manufacturing environment continues to ask more and more from your shop, from 24/7 production to maintaining peak operating capacity and more. The eX Plus series is designed to answer even your most challenging production problems.

Built on a heavy-duty, single platform, the eX Plus series incorporates crucial improvements in movement speed and piercing power over the previous LV Plus II model—all while still being one of the most cost-effective CO2 laser machines on the market.

TOP PERFORMANCE FOR TOP PRODUCTIVITY

- Spend less time fixing mistakes and more time shipping products out the door. Whether you’re working with thick-plate stainless steel or high-grade aluminum, Mitsubishi CO2 laser machines can produce best-quality beams that leave your edges smoother, burr-free and aberration-free.

EASY TO USE, EASY TO MAINTAIN

- When allowed to take advantage of industry-leading Mitsubishi consumable components, the eX Plus series requires very little service to maintain. The on-board, PC-based CNC system allows your teams to make short work of almost any project.

HIGH-POWERED CUTS, LOW OPERATING COST

- The operating costs associated with Mitsubishi CO2 laser machines are lower than any other CO2 lasers on the market—even coming close to the low costs associated with fiber laser machines. That’s just one of the many reasons why laser fabrication technology from Mitsubishi—a market leader since 1977—is a great match for any business that values consistency.

CAPABILITIES:

- Reduces processing time by as much as 50% thanks to its high-speed, heavy-duty motion system

- Improves gas change time by 60% over the previous model (approximately 10 minutes from startup)

- Advanced “Diamond Path” beam delivery system allows tight beam control for exceptional cutting performance, superior edge quality, and processing consistency over the entire work area

- Aggressively pierces mild steel with built-in Jet Pierce capability

- Designed to deliver better editing & graphical capabilities and faster calibration

- Allows for increased energy savings via on-board ECO MODE

COMPONENTS:

- An ultra-rigid, ultra-stable, single-platform, Dianite-cast machine frame to ensure optimal stability and processing accuracy—even at high speeds

- A helical rack and pinion setup to reduce noise and increase acceleration in X and Y axis while providing increased accuracy and longer lifetime

- A heavy-duty, high-speed pallet changer to maximize your throughput capacity

- A new PHXS head with new lens cartridge design, allowing for more constant centering and better performance (available in a 10″ focal length option)

- A standard magnetic head, allowing for quicker recovery after collision

- An on-board power & gas consumption monitor to help you manage your resources more effectively

- A Mitsubishi safety package (includes full side covers and automatic door for processing area)

SYSTEM INFORMATION:

- PC-based, 64-bit NC control has touchscreen user interface and full network capability

- Features the latest Mitsubishi on-board CNC control with faster graphical interface, USB compatibility, and expanded programming options

- Processing time display improves worker efficiency by estimating processing time

ADDITIONAL BENEFITS:

- Nozzle changer option is now available

- remote360°-enabled (remote user monitoring, diagnostics, service support, and more)

| LASER MACHINE MODEL | 3015 eX Plus |

| Maximum Workpiece Size: in (mm) | 120.1 x 60.0 (3,050 x 1,525) |

| Rapid Travel Speed [X, Y]: in/min. (m/min.) | 3,940 (100) single axis, 5,550 (141) simultaneous |

| Machine Unit Dimensions: W x H x D in (mm) | 428.6 x 127.8 x 93.7 (10,886 x 3,246 x 2,380) |

| Automation Ready | Yes |

| Available Resonators: Model Number (Wattage Output) | 35CF-R (3500W), 45CF-R (4500W), 60XF (6000W) |

Zoom Fiber Head

Laser customer stories

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.

-

FIBER LASERS

A faster, tighter beam for higher cutting speeds and greater accuracy with thinner materials.

learn more -

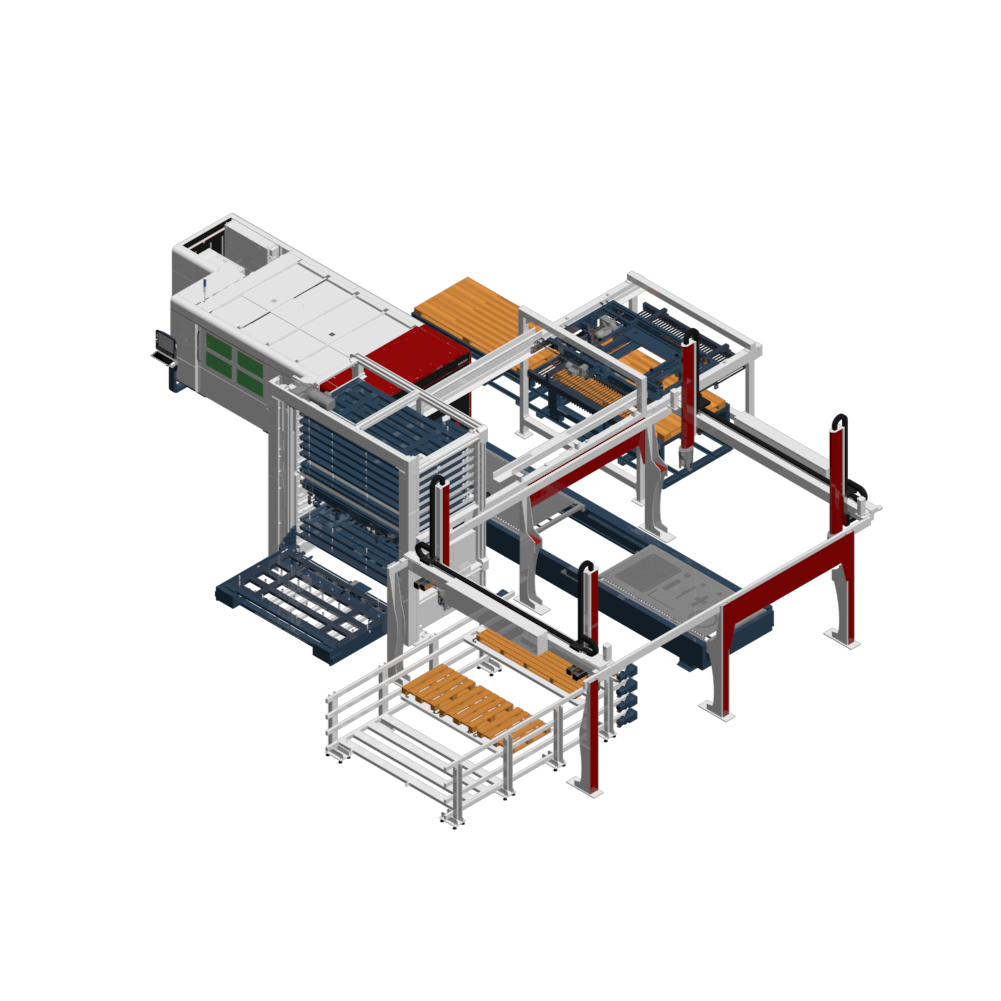

LASER AUTOMATION

Leave your bottom line beaming.

learn more -

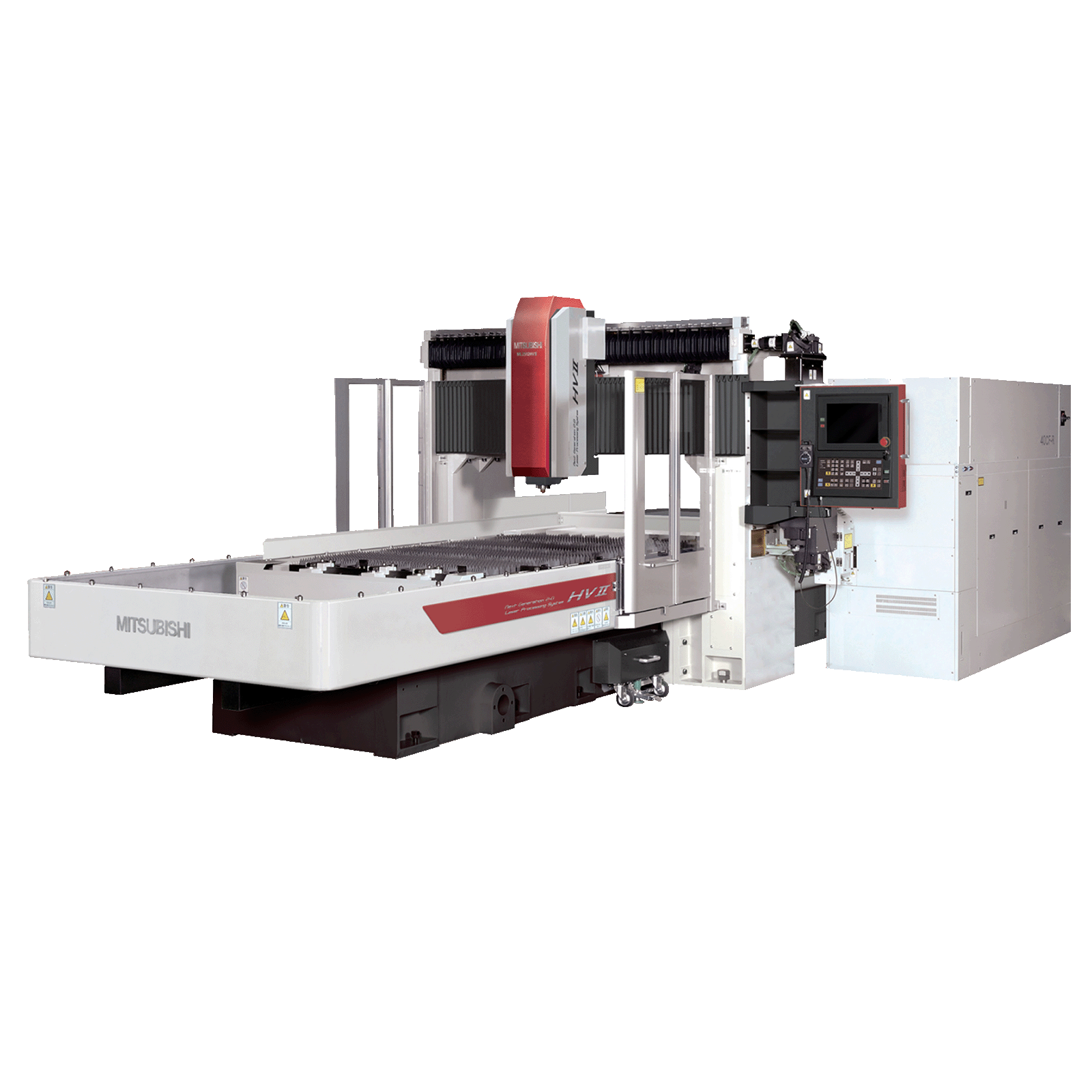

2D CO2 LASERS

Solid construction, advanced programming, and high-speed 2D cutting for thick-cut materials.

learn more -

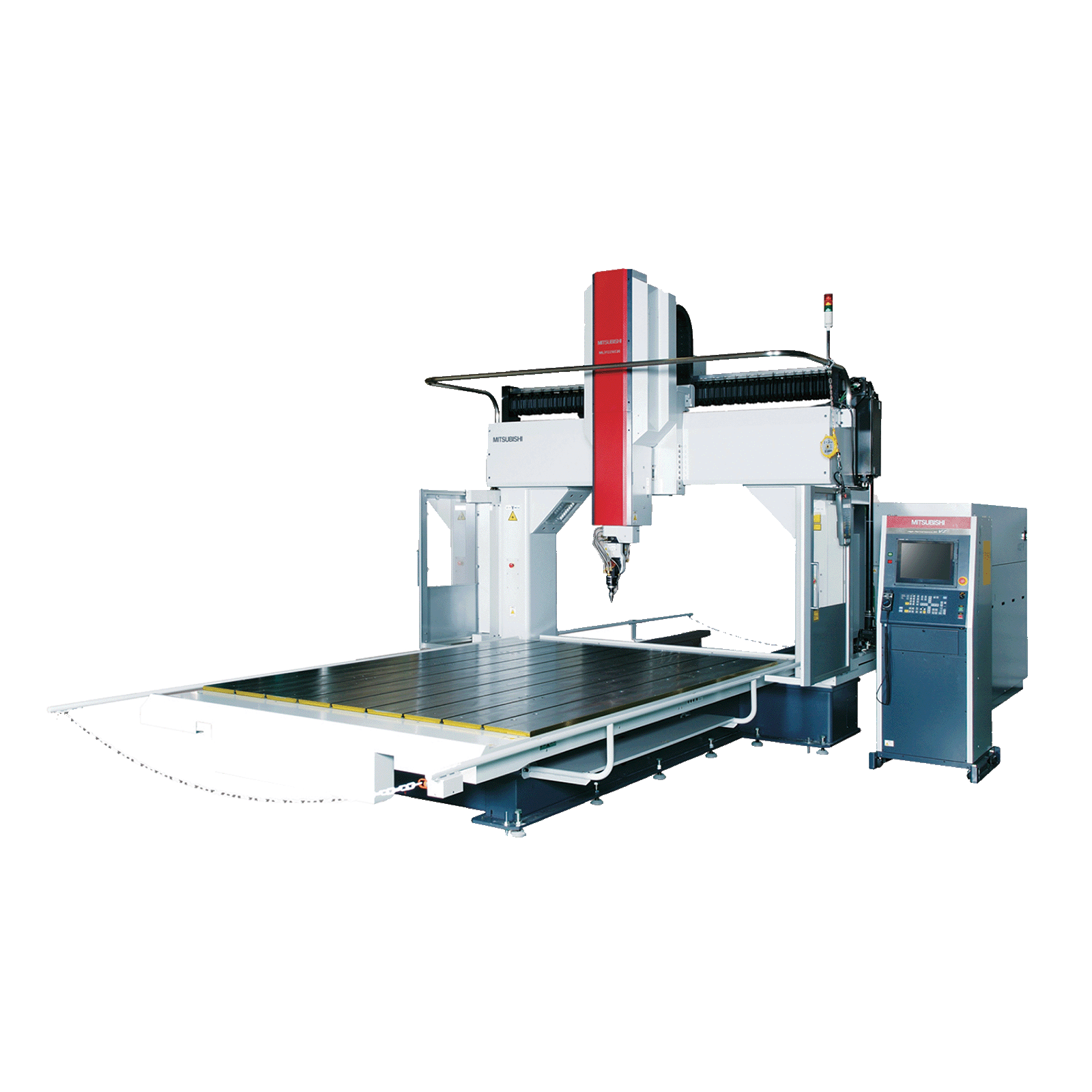

MULTI-AXIS CO2 LASERS

High-performance 3D laser processing for tough materials.

learn more

-

"We’re excited with all of the things that Mitsubishi Laser is bringing to the marketplace because it helps us achieve our goals of being profitable and having sustainable growth."

Si Cha, Olympic Steel's plant manager of the Buford location’s Fabrication Division learn more -

"It is just a mind-blowing, amazing machine. I had never been sold on fiber lasers because of micro-burr and concerns about edge quality, but the GX-F has burr reduction technology that makes burr non-existent."

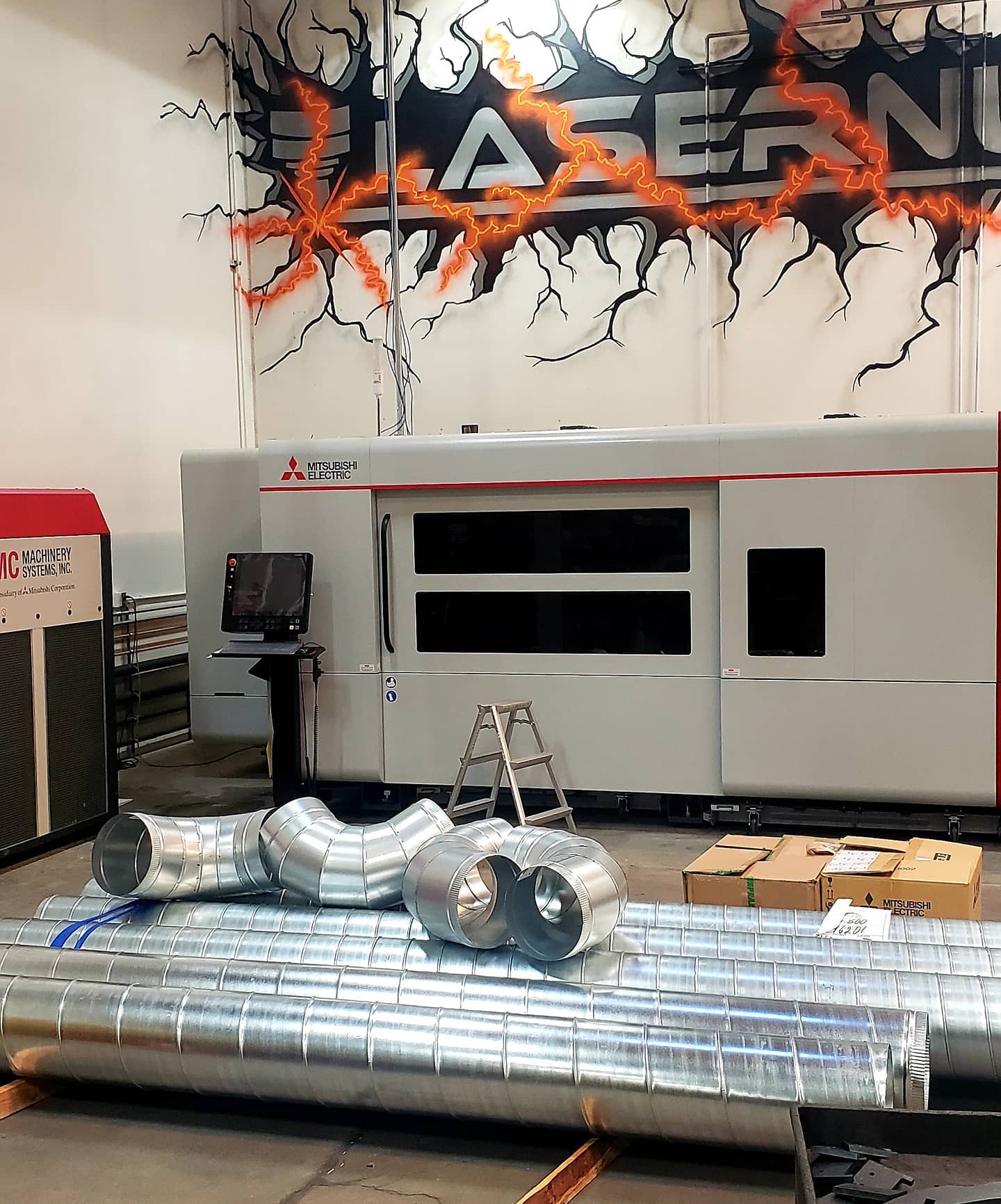

Cody Waggoner, President of Lasernut learn more