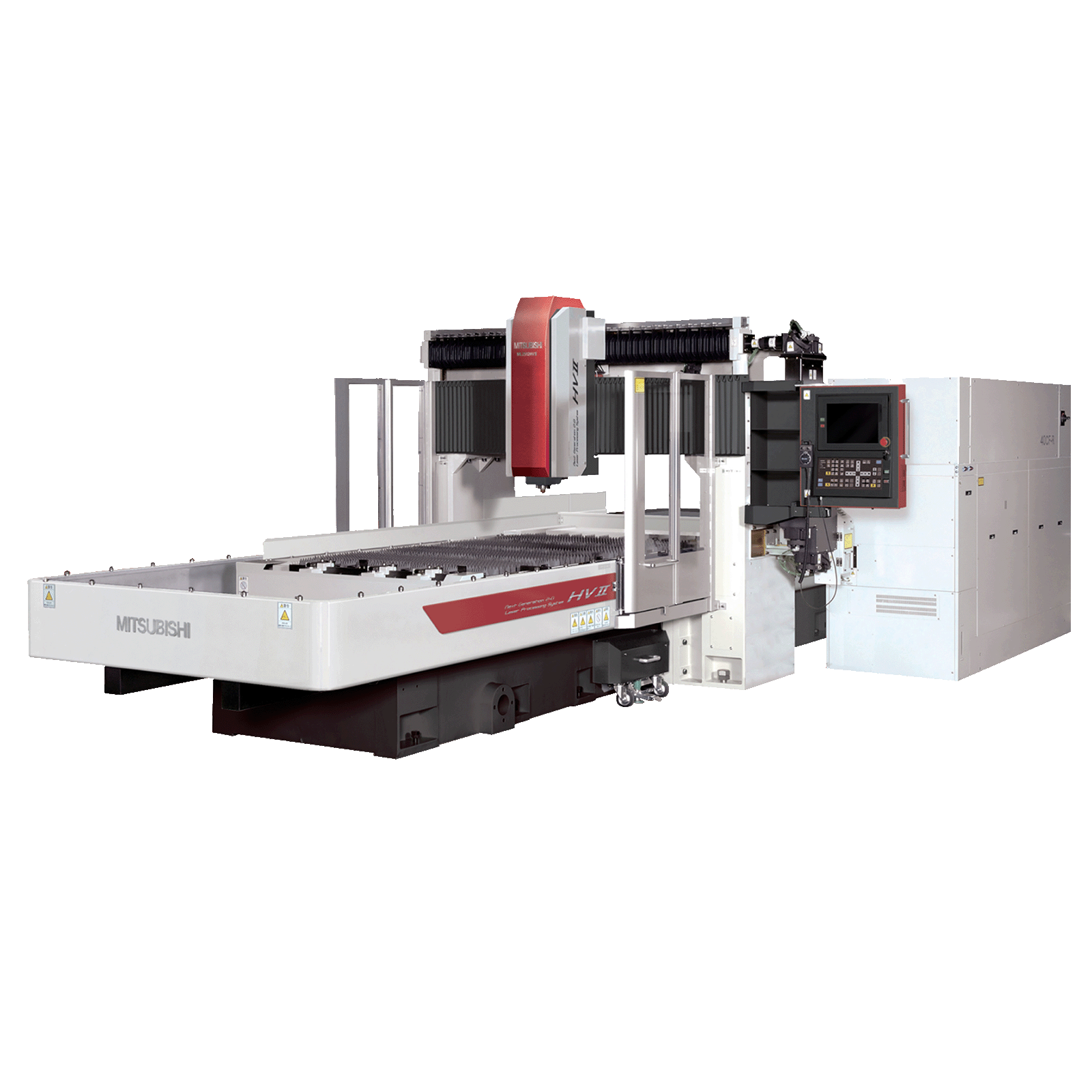

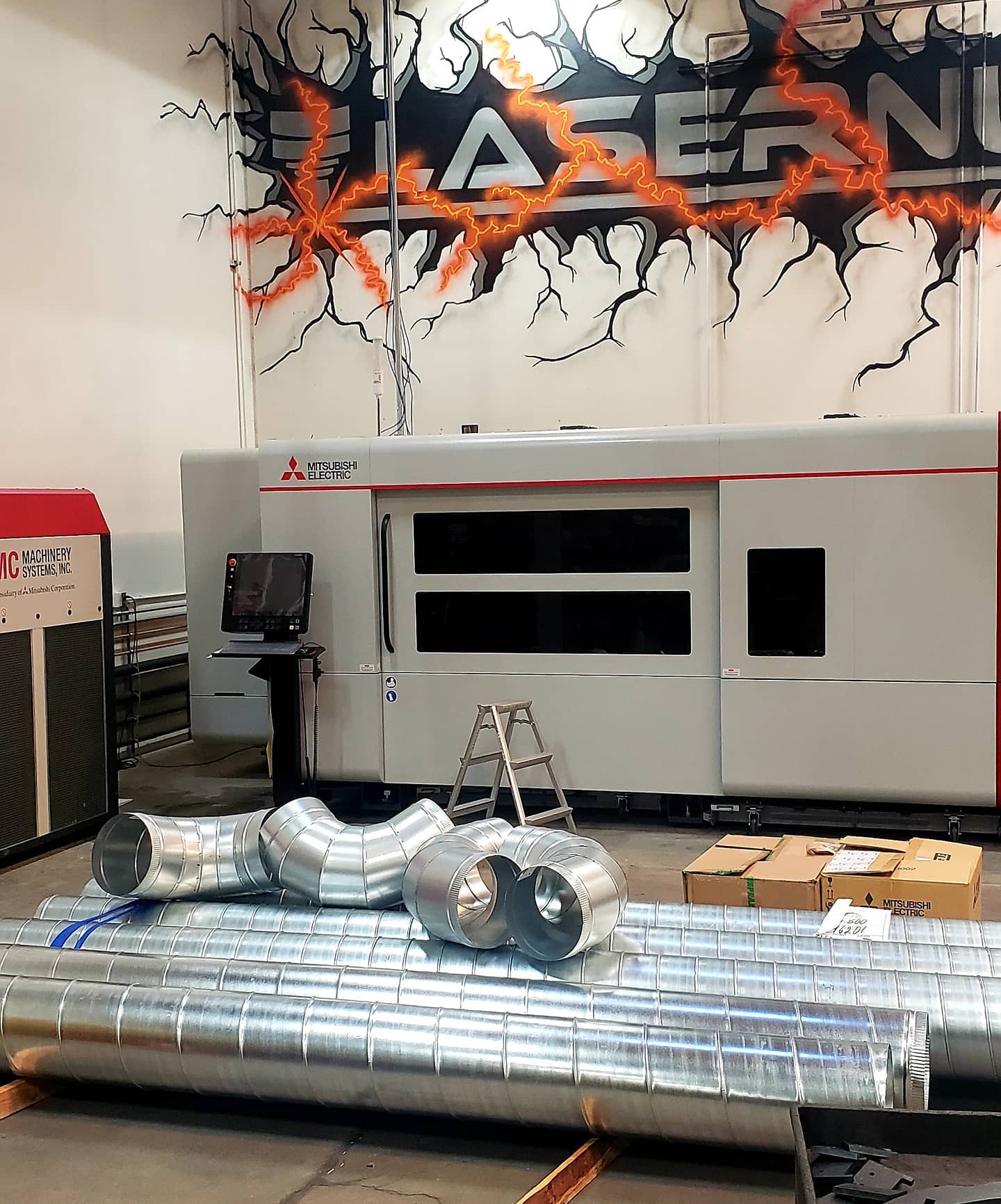

HVII-R Series

Powerful, versatile, and low cost of ownership. A lightning-fast “hybrid” CO2 laser in every sense of the word.

Equipped with state-of-the-art technology, the HVII-R series represents the newest addition to our “hybrid” line of CO2 lasers, bringing together the cutting power of most high-powered lasers in a small, economical form factor. It’s also one of the most versatile, user-friendly machines on the market.

The HVII-R series features advances in user accessibility, gas flow, beam quality, and processing capabilities—from normal flat-sheet processing to tubular and preformed parts—while still allowing for exceptional plate-processing performance. In every way that counts for your business, the HVII-R series brings unsurpassed performance at the lowest cost of ownership of any machine in its class.

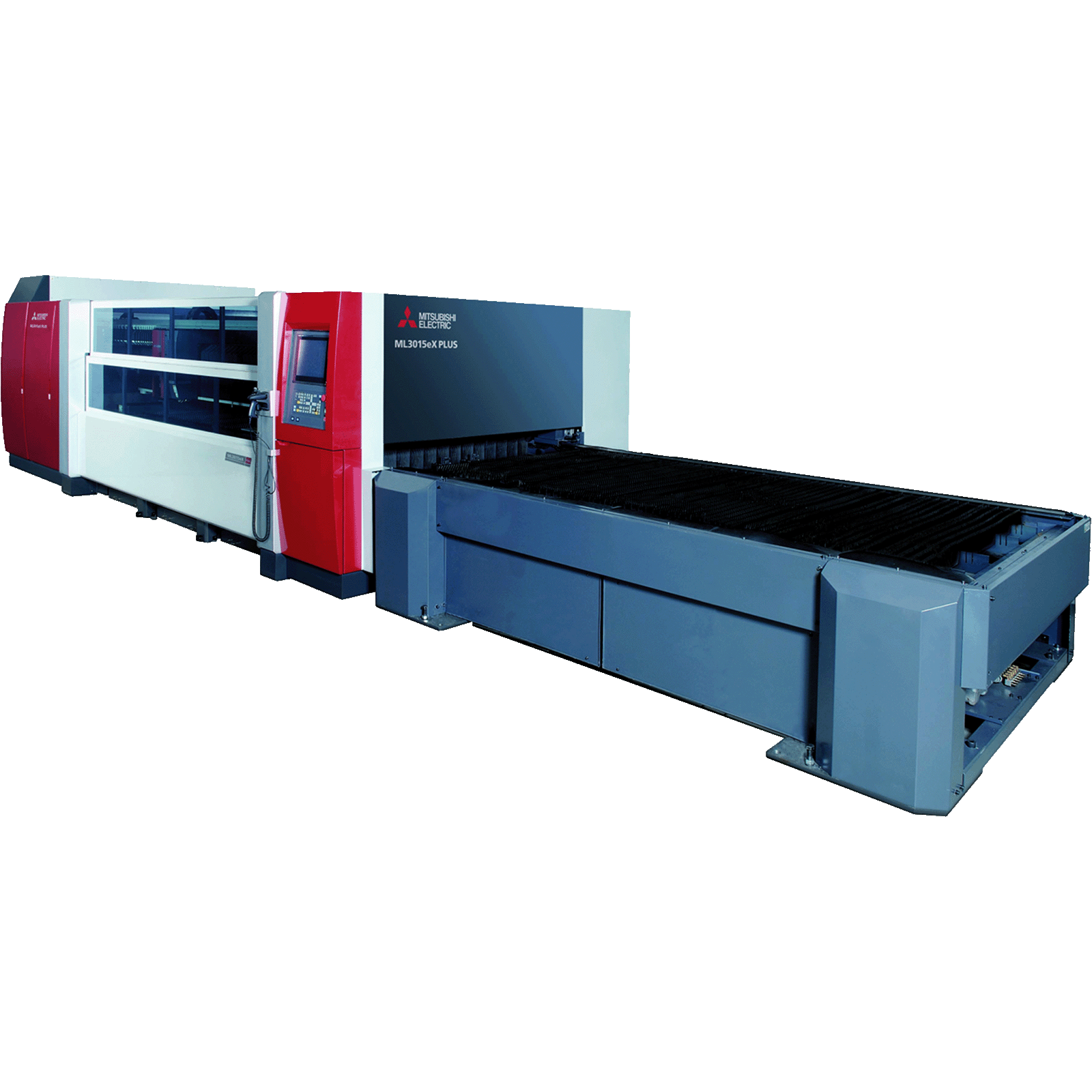

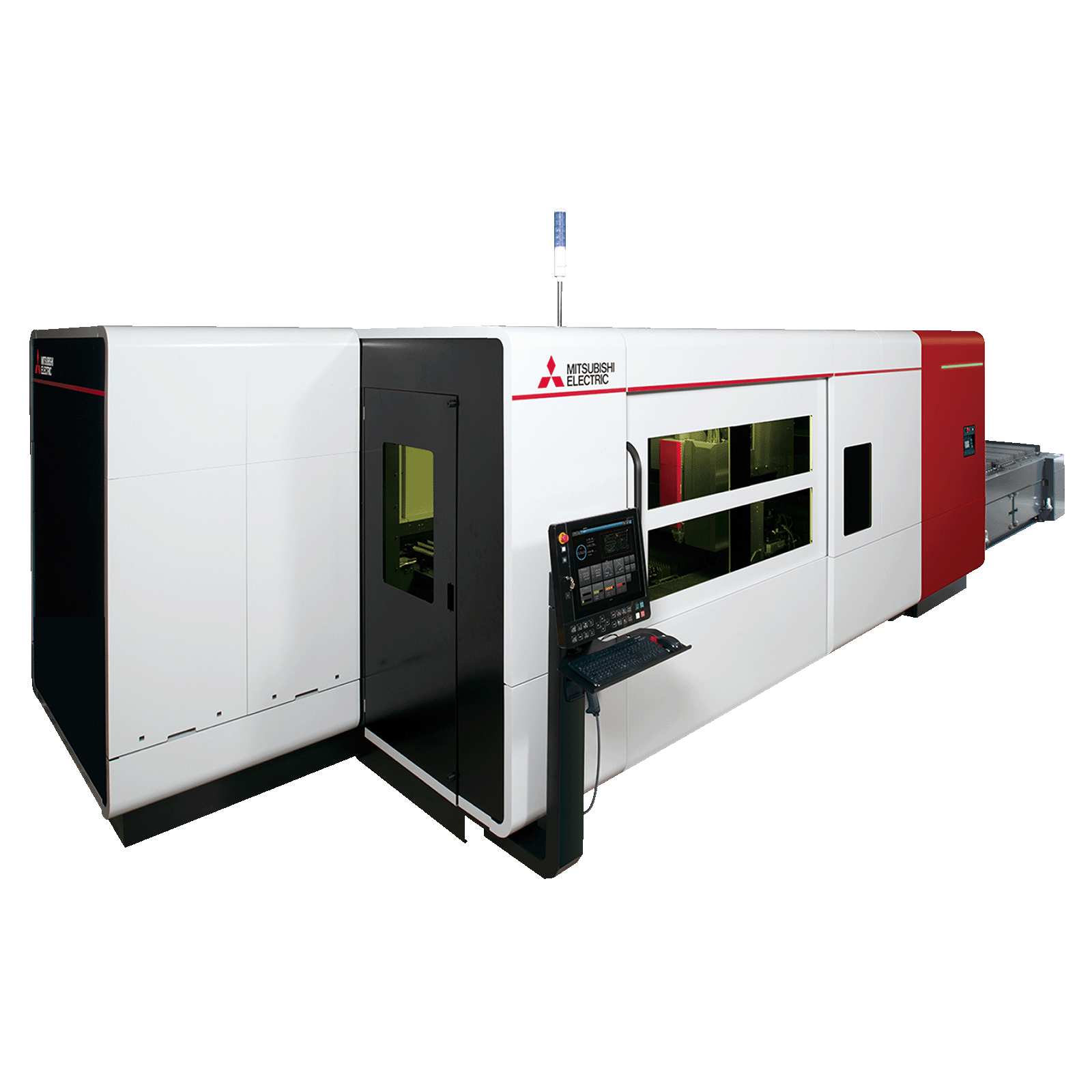

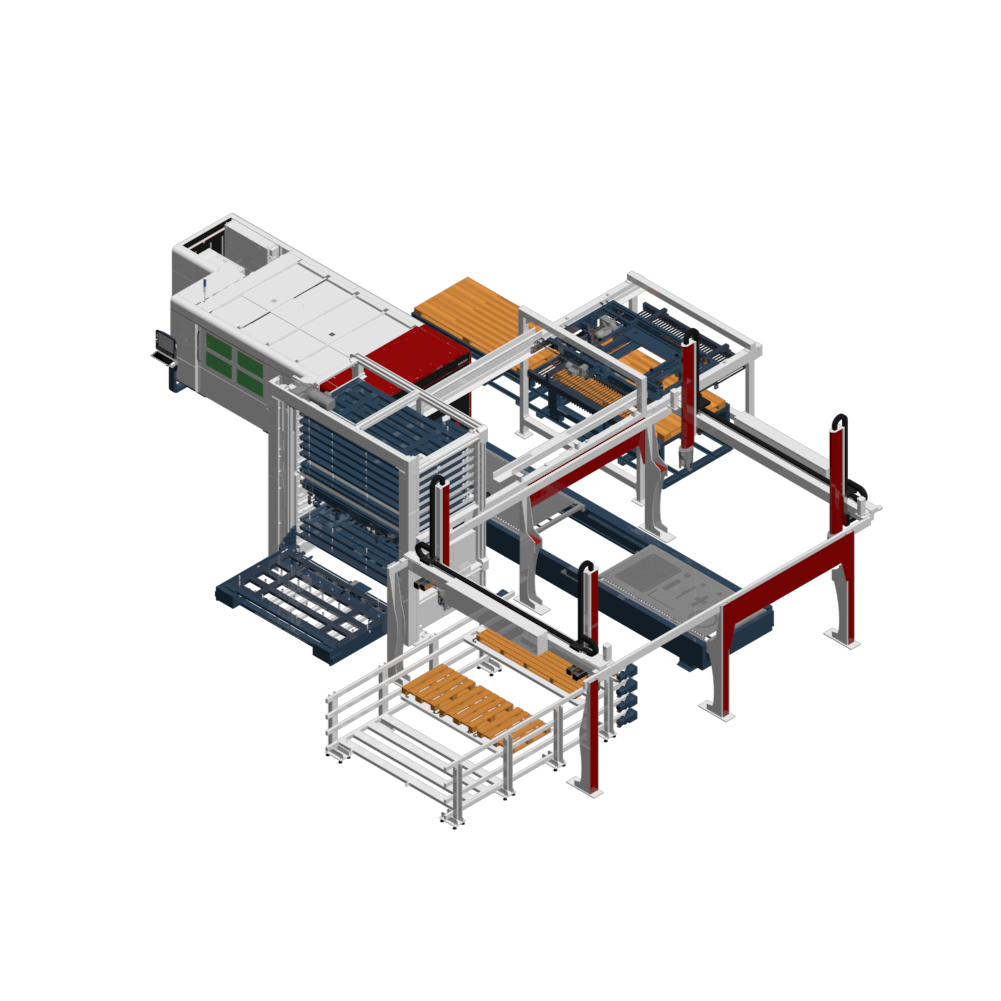

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.