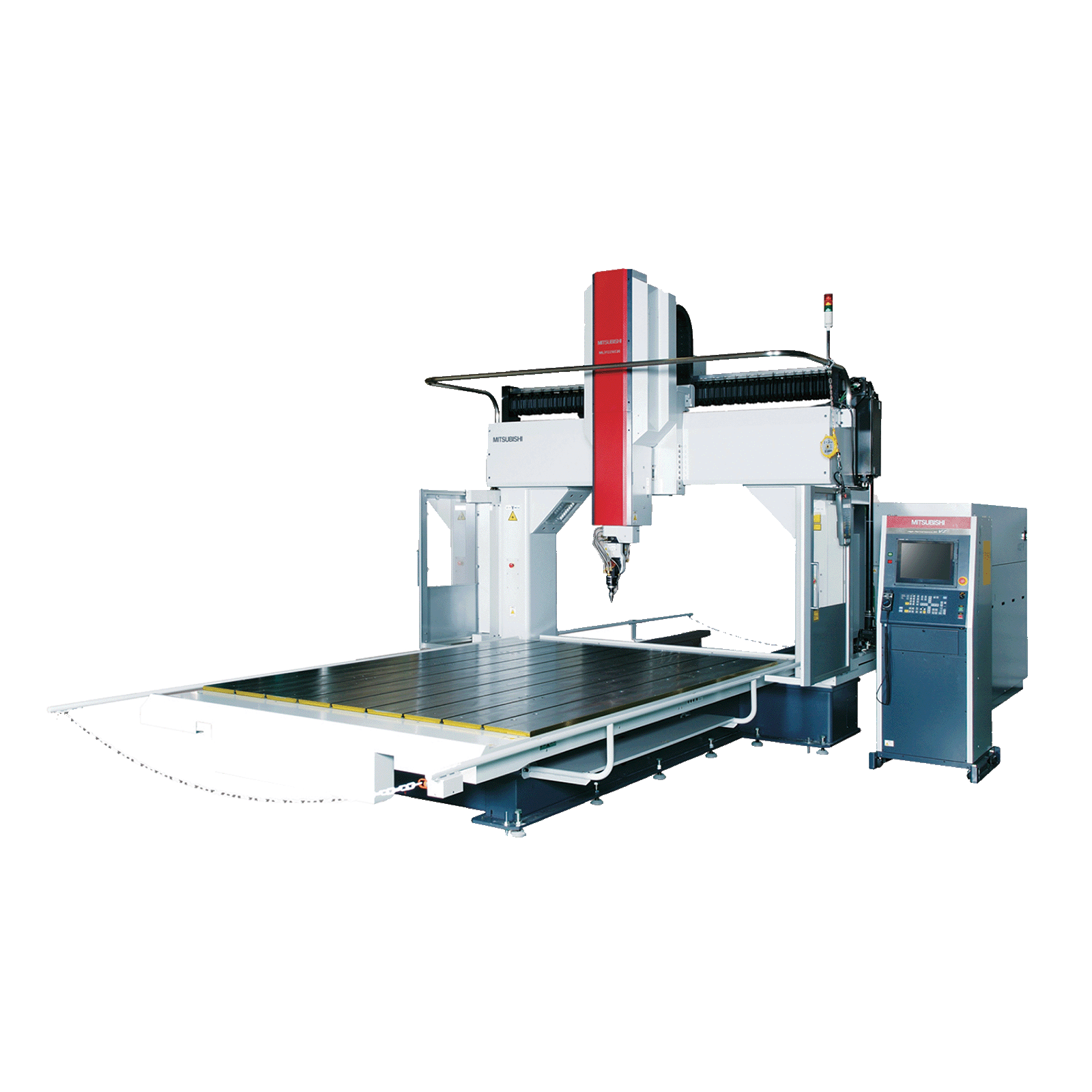

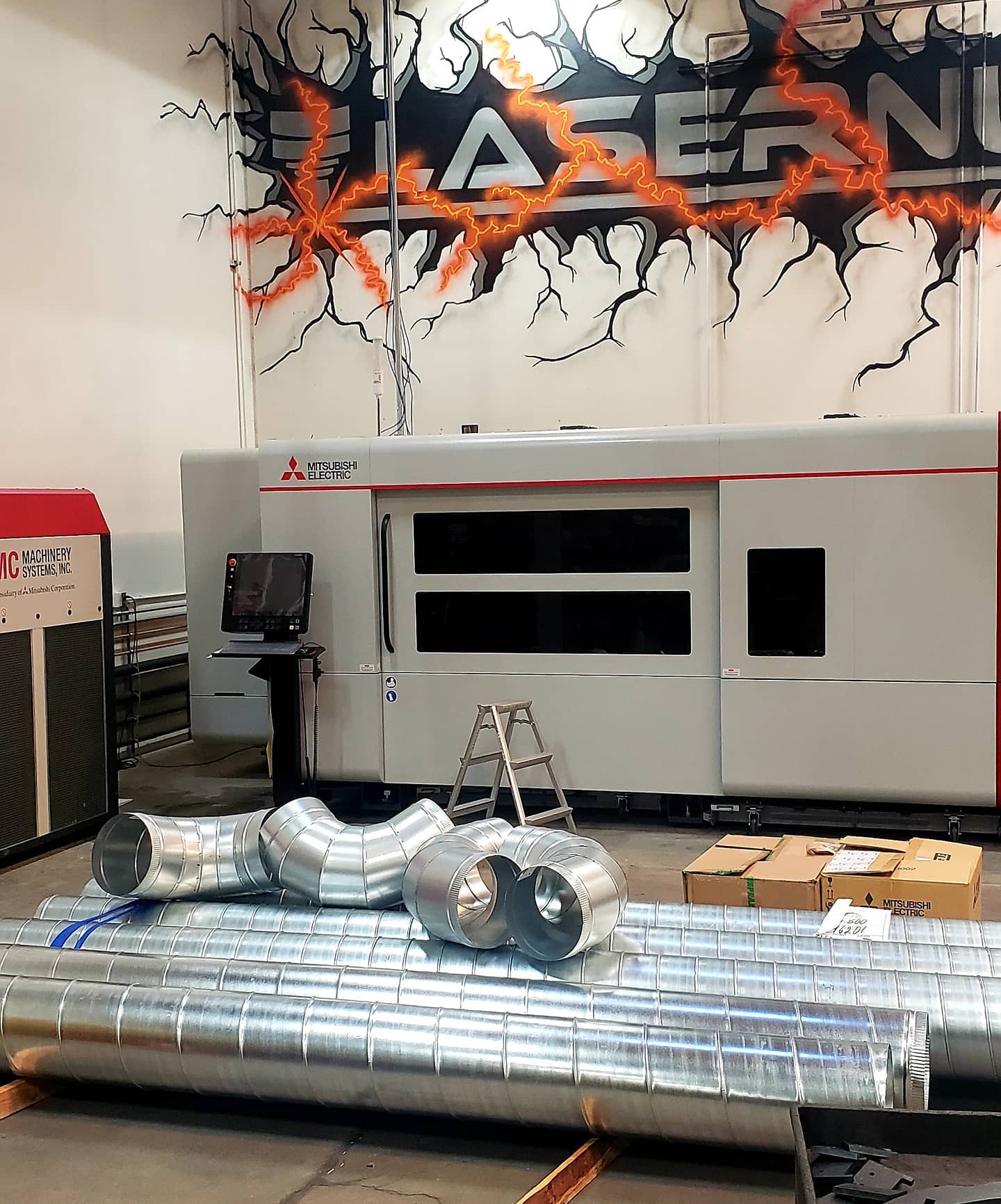

XL Series

For when you need to deliver quality and quantity at the speeds your production line needs.

You know better than most that when it comes to the manufacturing industry, your shop’s bottom line relies on both high productivity and quality performance.

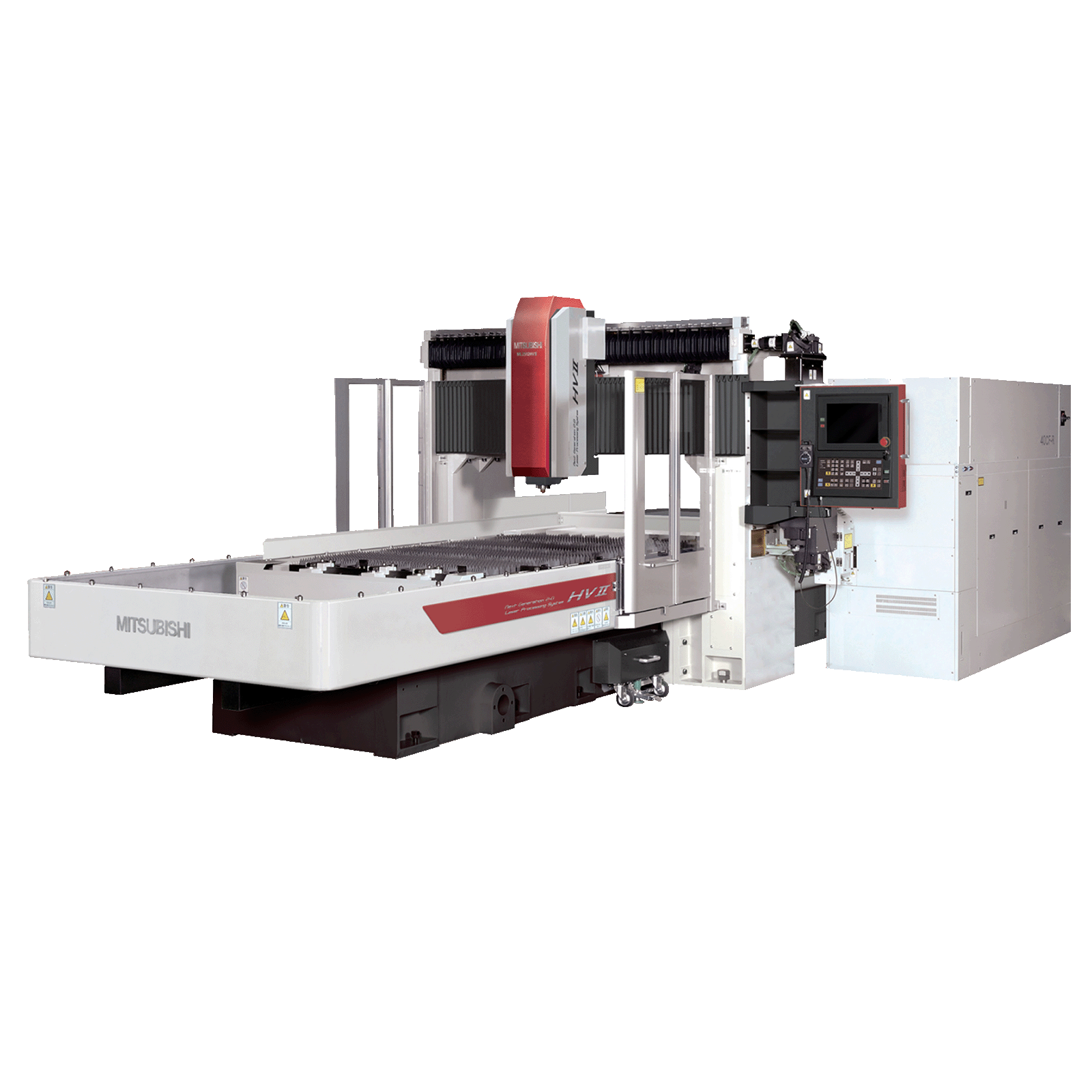

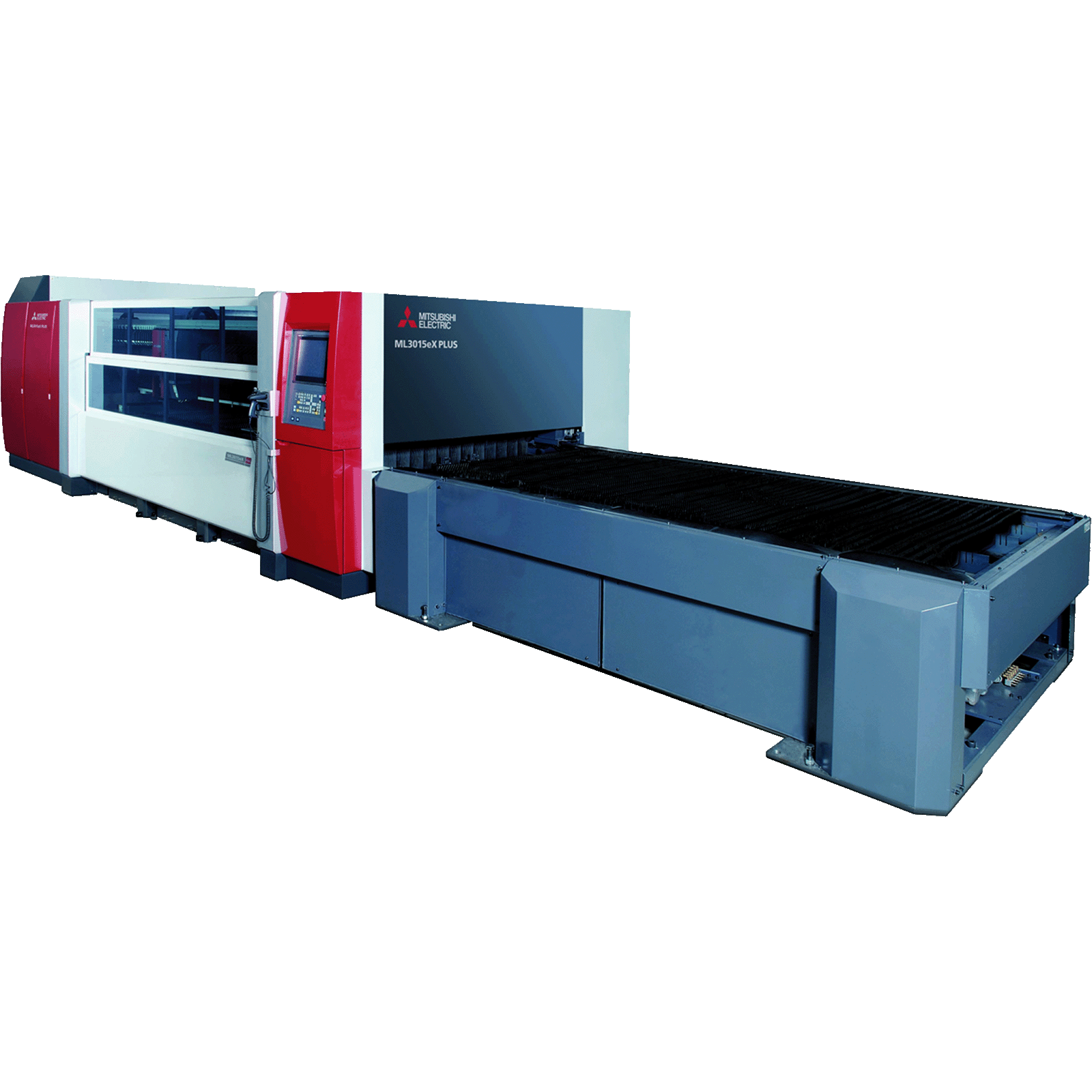

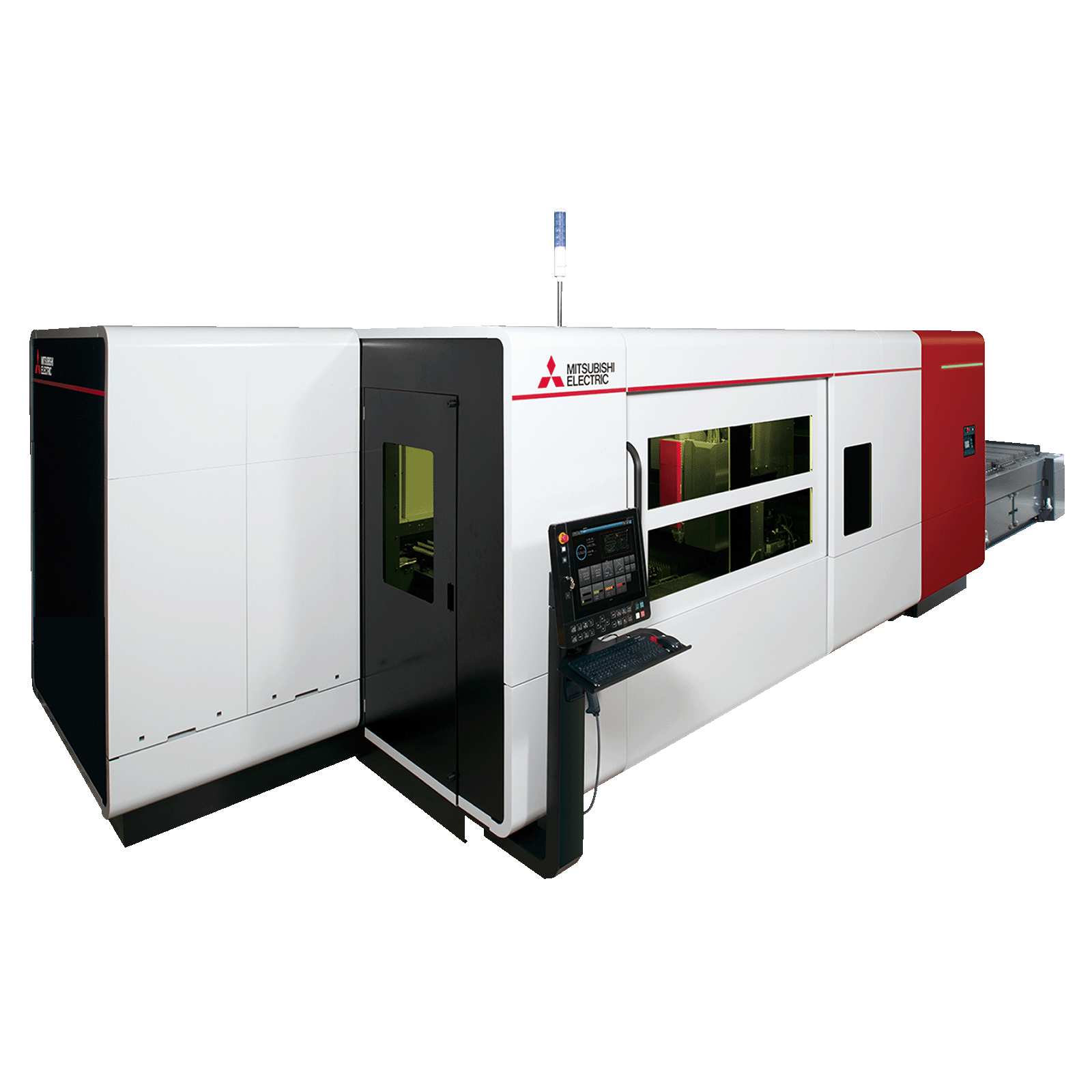

The XL series of CO2 lasers from Mitsubishi achieves both through its large-scale processing capabilities and quality performance. Its flying optic design provides diverse applications at high speeds, and its large work area allows for precision cutting. From performance you can count on to unrivaled production capacity that gets results, the XL series offers a comprehensive solution for any shop’s needs.

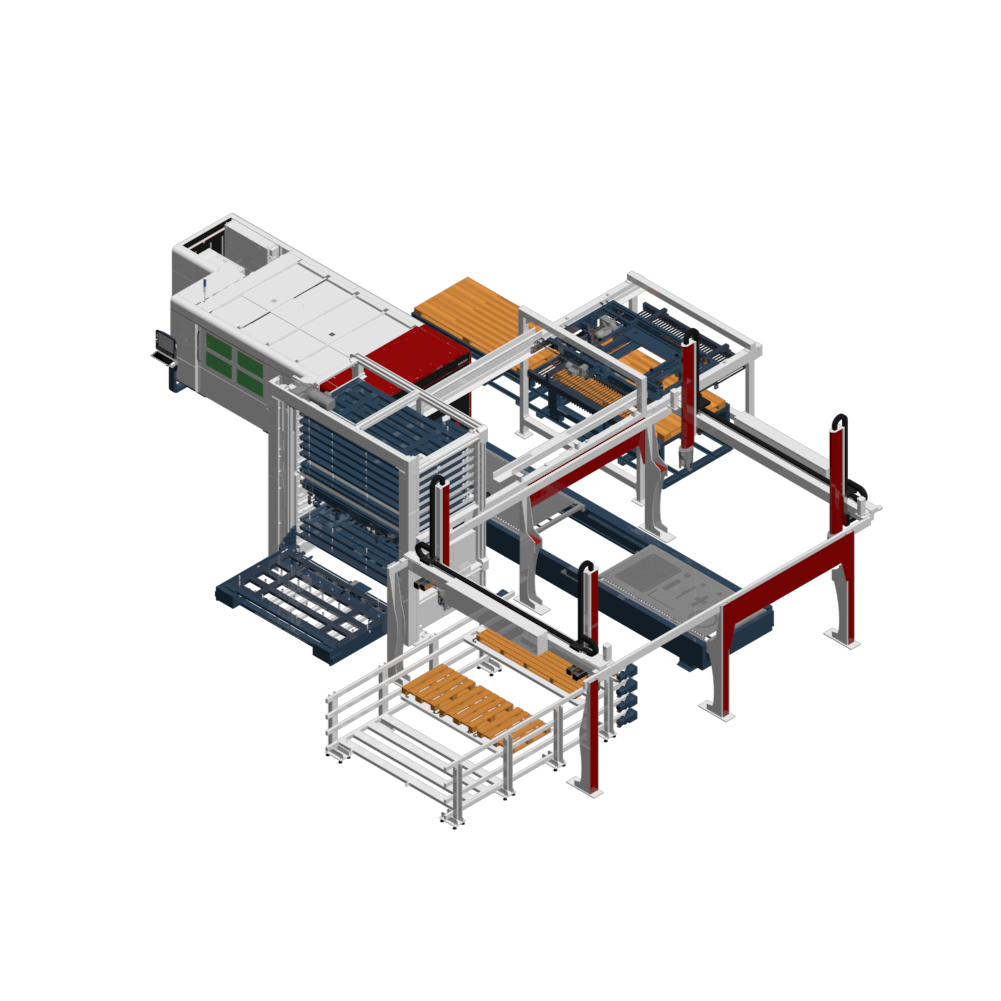

RELATED SOLUTIONS

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.