These compact, cost-efficient press brakes are the best choice for quick, quiet, high-quality work.

LEARN MOREOur energy-efficient, all-electric BB Series of Mitsubishi press brakes has performance-enhancing features that are perfect for meeting and exceeding the demanding requirements facing today’s fabricators.

BB Series press brakes are the perfect blend of serious bending power and cost-efficient operation that doesn’t sacrifice quality or output.

Searching for the perfect blend of serious bending power and cost-efficient operation that doesn’t sacrifice quality or output?

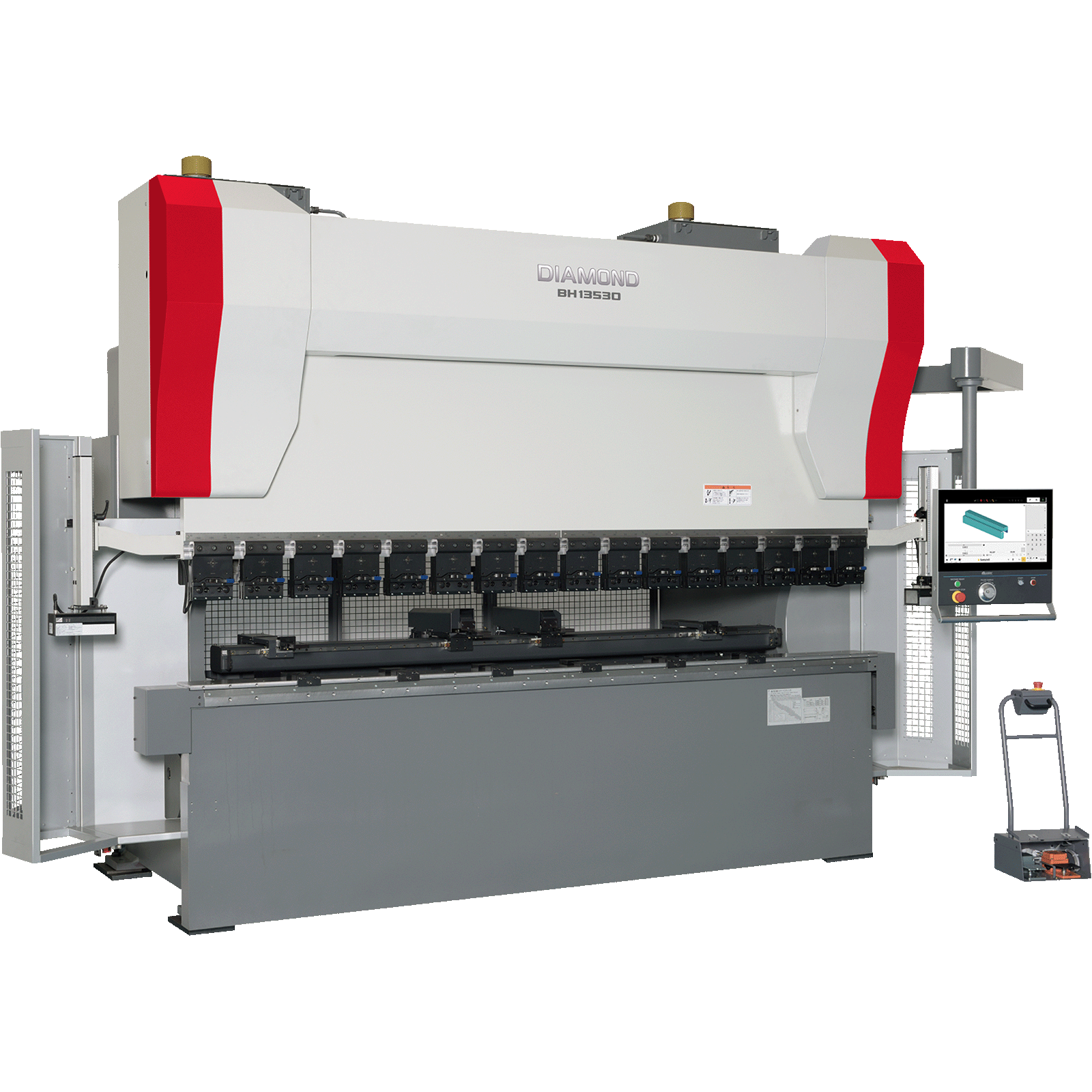

The BH Series of Mitsubishi hybrid press brakes have a patented dual-drive design that combines best of both hydraulic and electric bending: productivity, precision, high-speed movement, reliability, and superior energy savings.

Ranging from entry-level hydraulic all the way up to heavy-duty, fully customized solutions that cover any of your requirements for sheet metal forming, our PA Series and PH Series of ADIRA press brakes represent the apex of pounds-to-performance for industrial bending.

In addition to their robust production capabilities, the PA Series and PH Series of press brakes are equipped with intuitive operator controls that take the stress out of day-to-day operation for operators of any skill level.

A press brake fitted with a Mitsubishi automatic tool changer (ATC) can manage and optimize your workflow to save time, money, and labor. Avoid and actively prevent costly downtime and product defects.

Fine-tune your shop with unmatched programmability, functionality, and real-time, cloud-based machine insights. Whatever the challenge, there’s an automation solution that can help.