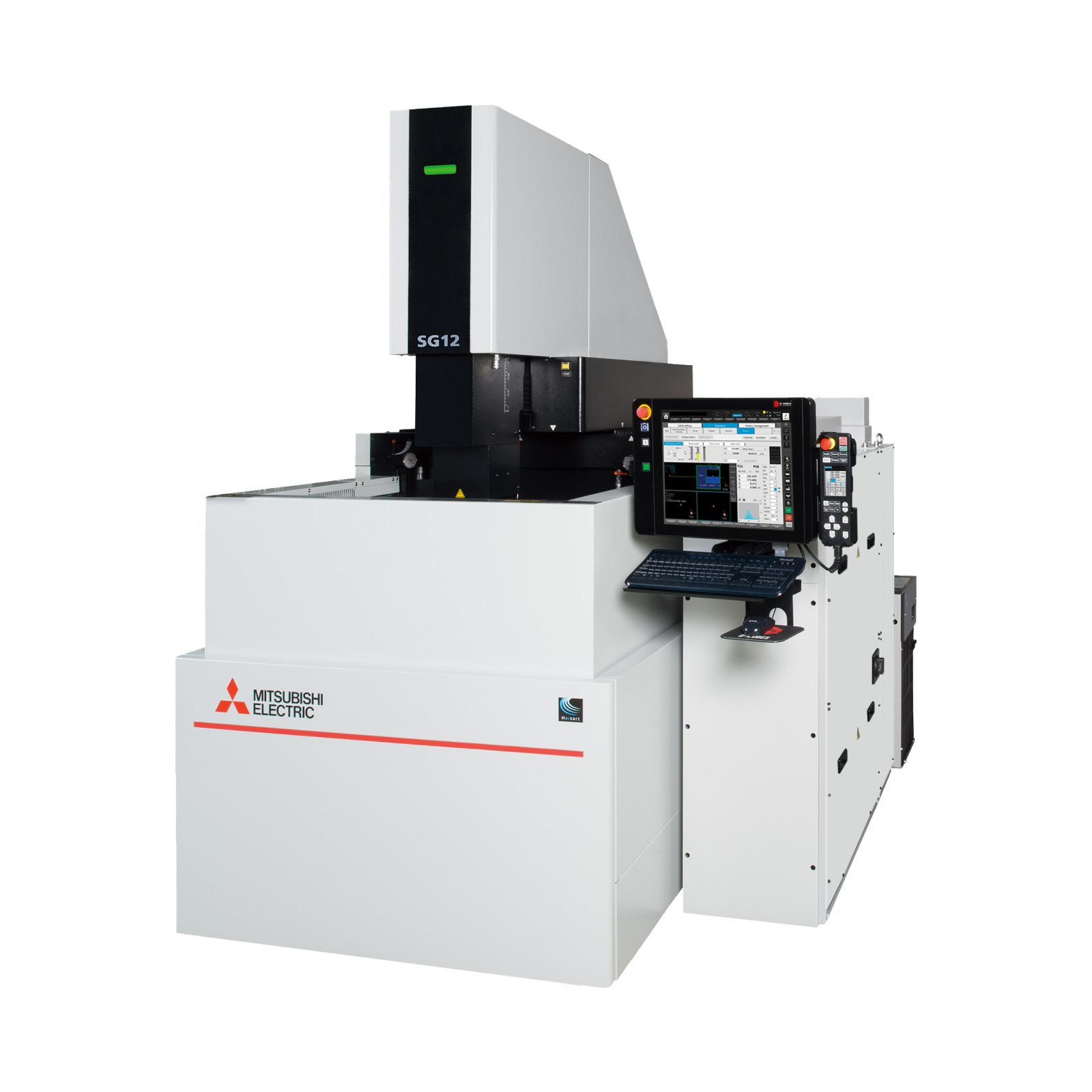

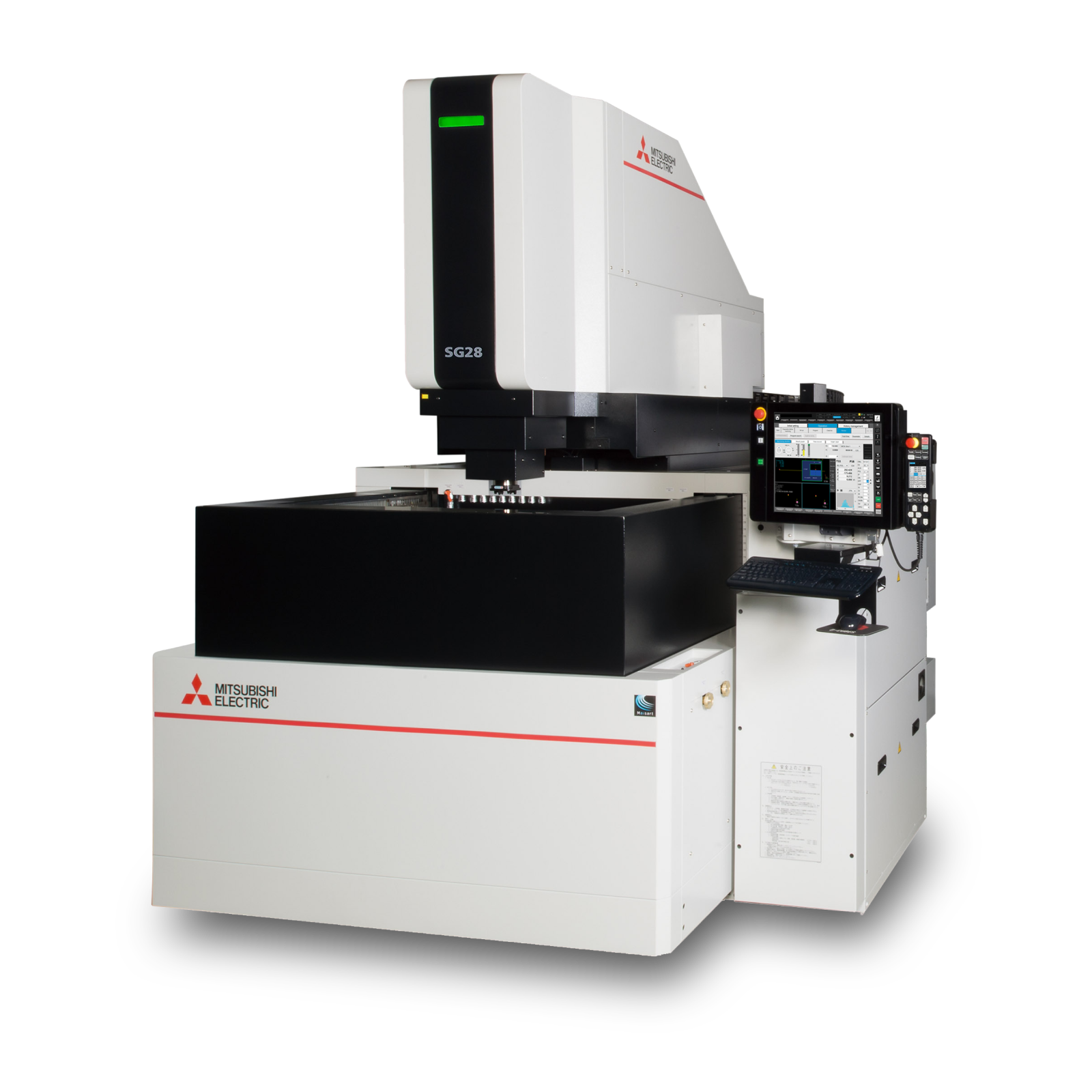

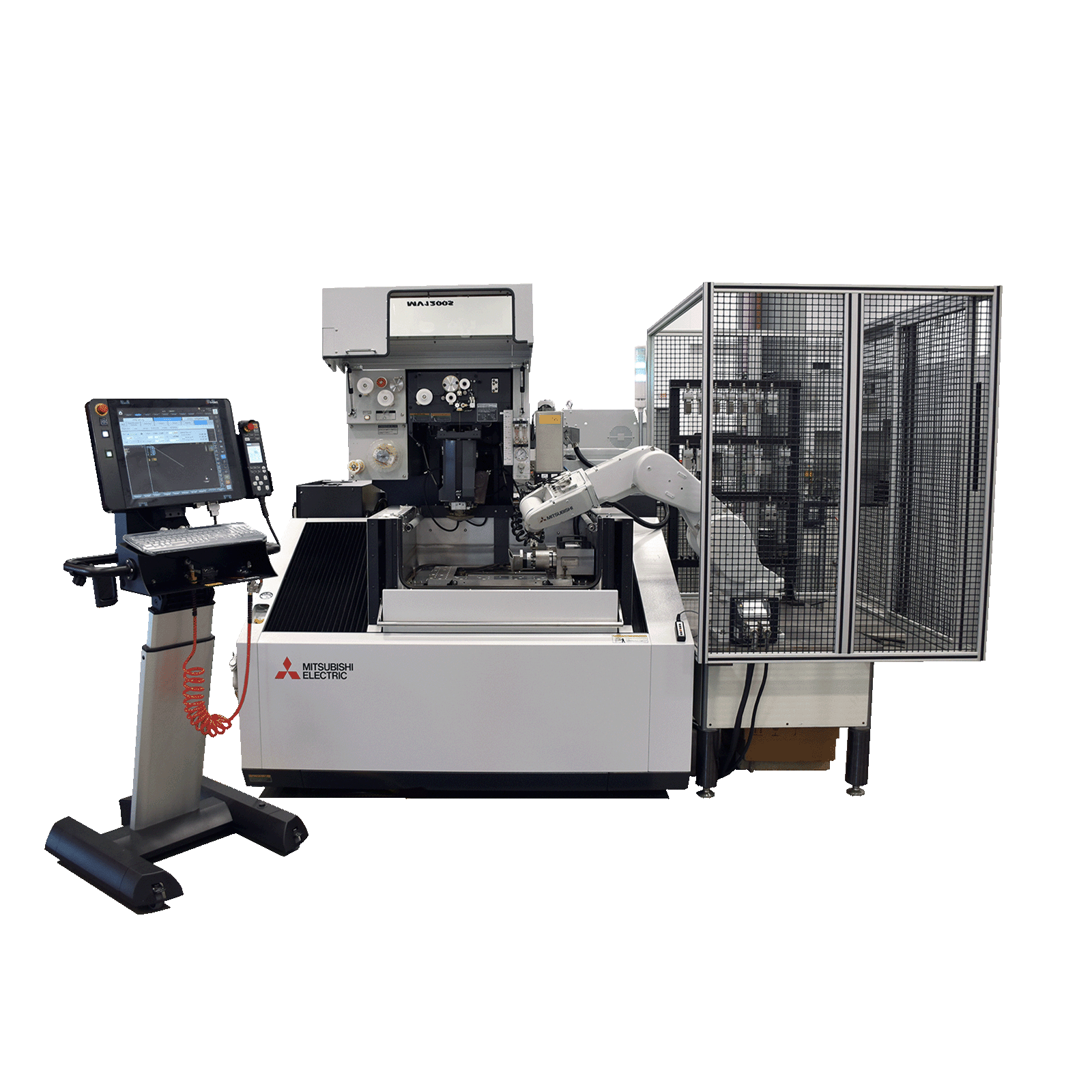

EA8PS Advance Sinker EDM

High-accuracy, high-grade Sinker EDM you can trust – for micro-fine finish, mold & die, or small-hole applications.

The EA8PS Advance can produce a variety of finishes while still maintaining the degree of quality and high-accuracy precision the world expects from Mitsubishi machines. The EA-PS series offers truly high-grade sinker EDM solutions that generate serious cost savings down the road—from hands-off, low-maintenance components that keep your shop floor humming to intuitive user-focused design that requires less learning, so you can spend more time doing.

BUILT TO PERFORM, BUILT TO LAST

- The Mitsubishi EA8PS Advance with Thermal Buster is the ideal choice for tight-tolerance applications such as die and mold.

- The new Thermal Displacement Compensation System and Z axis cooling mechanism improve accuracy by tracking and compensating for machine temperature changes.

EXTREME VERSATILITY & UTILITY

- The standard granite table and NP2 circuit provide ultra-fine, satin surface finishing anywhere on the table surface.

- An enhanced glossy mirror finishing circuit, LLTX “Lotus Leaf TeXture,” improves mold release without the need for polishing.

- If you work with exotic materials such as PCD, cBN, or carbide, the HPS circuit enhances machining speed while reducing electrode wear.

COST- AND USER-FRIENDLY

- The FP80PS energy-saving power supply reduces electrical consumption by 20% (compared to the previous FP model).

- Like most EDM machines, the EA8PS features the new Mitsubishi M700 series control with a 64-bit RISC processor and 15” touchscreen for easier user interface.

CAPABILITIES:

- High-speed rapid travel: 275”/min. (7m/min.)

- SS Jump 5 with 984”/min. (25m/min.) jump speed @ 1.6G acceleration

- Can produce a variety of finishes, including:

- Ultra-fine matte finishing with the NP2 circuit standard (0.05µm Ra)

- Fine matte finishes with the PS circuit

- Super-low wear with the SC circuit

- Glossy mirror finishing with the LLTX “Lotus Leaf TeXture” system

- Handles exotic material machining, PCD, cBN, and carbide, with the HPS circuit

- Fuzzy Pro Plus enables greater hands-off operation for better usability

COMPONENTS:

- FP80PS power supply (provides 80 Peak AMPs)

- Compact, highly rigid machine design

- Fixed table traveling column construction

- Direct drive AC smart servo system

- 3D lateral servo system

- Thermal Buster thermal displacement compensation system

- 3-sided drop tank worktank access

- 75” (70mm) thick granite table standard

- Easy-access filter system with one filter element

- Dielectric fluid emission

- Dielectric fluid chiller standard

- Narrow gap circuit

- LLTX “Lotus Leaf TeXture” system

ON-BOARD AUTOMATION:

- Automatic lubrication system

USER INTERFACE:

- M700 series CNC control with 15″ touchscreen

- Standard USB and Ethernet data inputs

SYSTEM INFORMATION:

- 40GB hard drive with a 1GB partition for user program storage

- IDPM “Intelligent Digital Power Master” adaptive control

- Anti-virus protection

- S.P.E.R. Advance Pro Lite programming & program support functions

ADDITIONAL BENEFITS:

- Full 2-year warranty with Triple Diamond Partnership Program

- remote360-enabled (remote user monitoring, diagnostics, service support, and more)

- Comes with one complimentary preventative maintenance visit—to be used by the end of 1styear

| Machine Travels X x Y x Z: in (mm) | 11.8 x 9.8 x 9.8 (300 x 250 x 250) |

|---|---|

| Maximum Workpiece Size W x D x H: in (mm) | 28.7 x 19.3 x 7.8 (730 x 490 x 200) |

| Max Dielectric Fluid Level: in (mm) | 9.8 (250) |

| Power Supply (Option) / Peak Current | FP80PS / 80 AMPs |

| Internal Worktank Dimensions W x D x H: in (mm) | 31.5 x 20.5 x 10.2 (800 x 520 x 260) |

| Worktank / Door Type | 3-Sided Drop Tank |

| Max. Workpiece Weight: lb (kg) | 1,200 (550) |

| Table Dimensions W x D: in (mm) | 19.6 x 13.8 (500 x 350) [2.75 (70m) thick granite] |

| Max. Electrode Weight Manual Change: lb (kg) | 55 (25) |

| Table to Platen Distance Min ~ Max: in (mm) | 5.9 ~ 15.7 (150 ~ 400) |

| Table to C-Axis Chuck Distance Min ~ Max: in (mm) | 5.9 ~ 15.7 (150 ~ 400) EROWA ITS Chuck |

| Table to C-Axis Chuck Distance Min ~ Max: in (mm) | 5.2 ~ 15.1 (133 ~ 383) 3R MACRO Chuck |

| Minimum Command Unit / Resolution: in (mm) | .00001 / .000002 (.0001 / .00005) |

| Rapid Travel Speed: in/min. (mm/min.) | 275.5 (7) |

| High-Speed Jump Maximum: in/min. (m/min.)[G] | 984 (25)[1.6] |

| Linear Scale Resolution X, Y, Z-Axis Std.: µm | 0.05 |

| Filters / Type | 1 pc. / Paper Cartridge |

| Filter Tank Capacity: gal (L) | 71.3 (270) |

| Machine System Dimensions W x D: in (mm) | 60.2 x 78.7 (1530 x 2000) |

| Machine Installed Height: in (mm) | 84.3 (2140) |

| Machine System Weight: lb (kg) | 4400 (2000) |

| C-Axis Min. Indexing Angle / Drive Unit | .001º / .001º |

| C-Axis RPM Range | 10 or 20 |

| Fluid Temp. Control | Chiller Standard |

| Optional Internal Spindle RPM Range | 1 ~ 1500 |

| Automatic Tool Changer Options | MVH-20 |

| Power Requirements [KVA] | 200/220 VAC ±5% [6.8] |

| Compressed Air Requirements | 2.7 cu.ft./min @ 90-100 psi |

RELATED SOLUTIONS

-

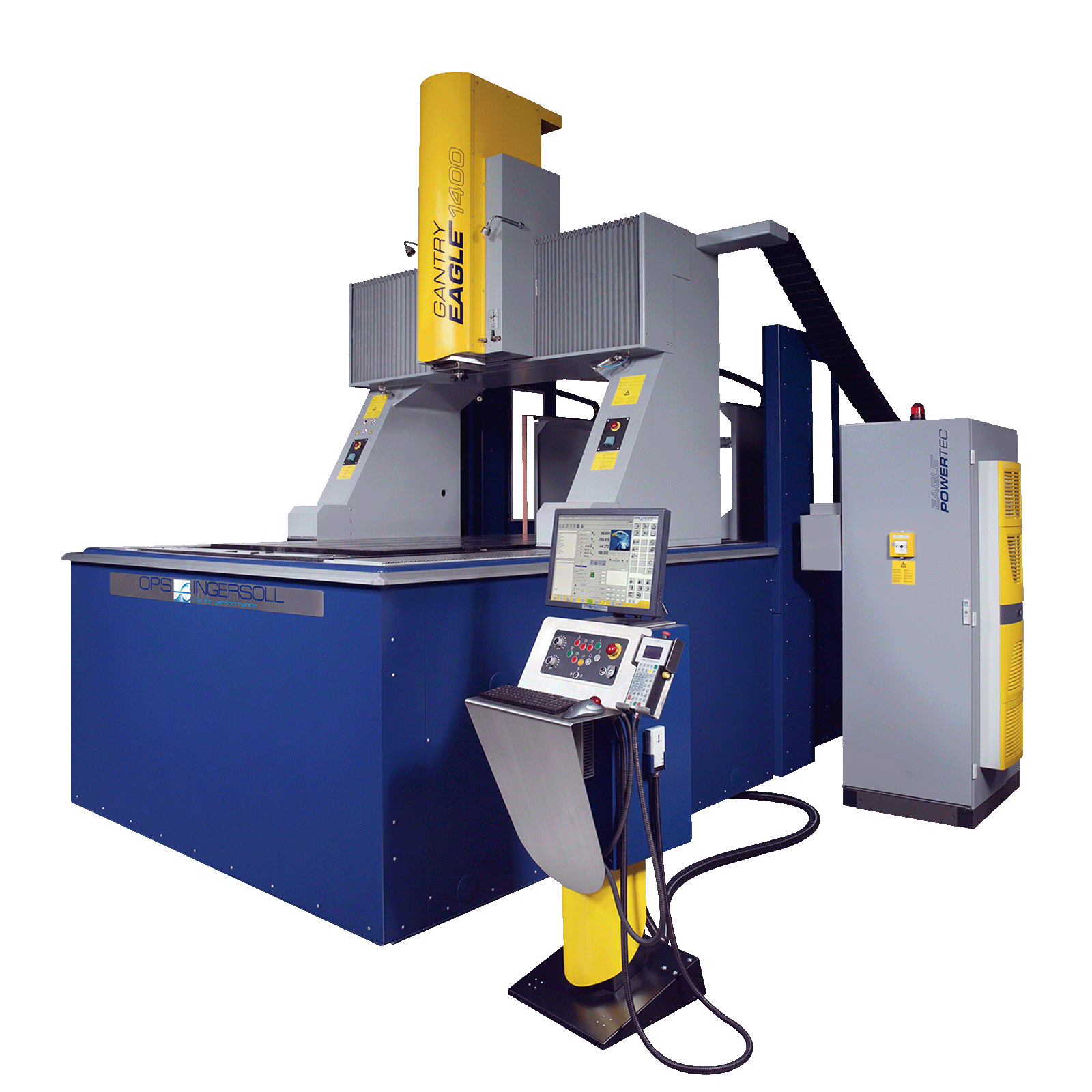

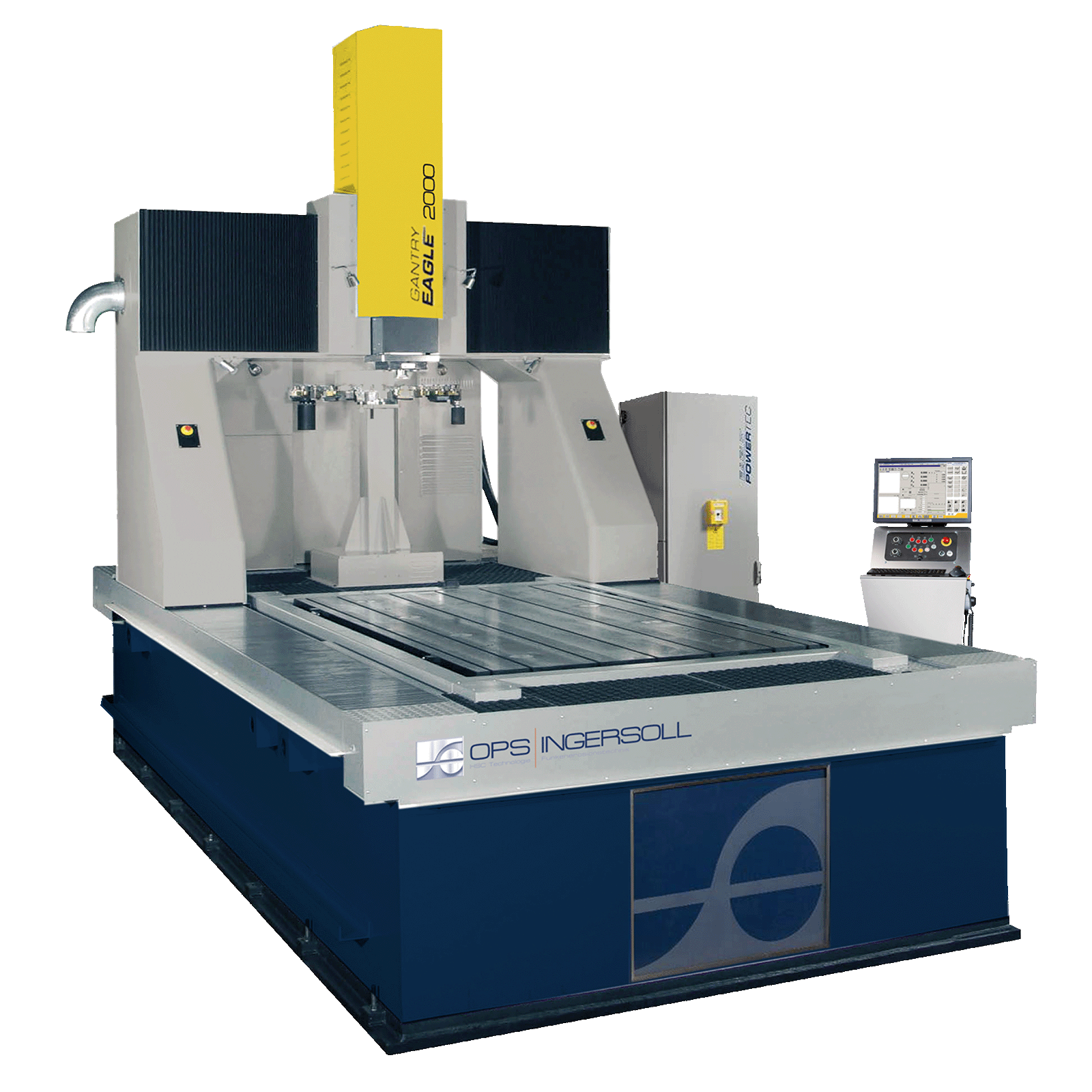

WIRE EDM

Simplifies the process of making parts and obtaining excellent tolerances using minimal manpower.

learn more -

SINKER EDM

Highly repeatable and reliable technology for applications requiring complex shapes, hardened materials, excellent accuracy and consistent surface finishes.

learn more -

EDM AUTOMATION

The ultimate solution to improve throughput, increase production, reduce manpower and be more competitive.

learn more

-

"The biggest thing for me with Mitsubishi EDMs is the accuracy is far superior to other machines I’ve used in the past. Putting a part in the machine, touching off the part, taking it out and it being the right size and location—it’s there all the time."

Adam Hall, Quality Tool & Die EDM operator Read case study -

"The quality and repeatability of Mitsubishi EDMs is second to none."

Aaron Wiegel, President of Wiegel Read case study -

"Overall, the machine itself is just reliable. Out of all the other manufacturers I’ve used over the years, working with Mitsubishi EDM has been one of my best experiences."

Danny Ritchie, head of Wire EDM Department at Dies Plus (a division of OTTO Engineering) Read case study -

"You don’t have to do anything but push a couple of buttons and it goes to mid points, center points–everything you want is right there on the pendant. It makes life simpler. This thing is touch off, write the program, hit the start button and the machine does it for you."

Daryl Bosco, Quality Tool & Die sinker EDM operator Read case study -

"When it comes to applications expertise, it’s a lot more difficult in any industrial OEM to find the breadth and depth that Mitsubishi EDM has."

Jeffrey Taylor, Crafts Technology President and General Manager Read case study