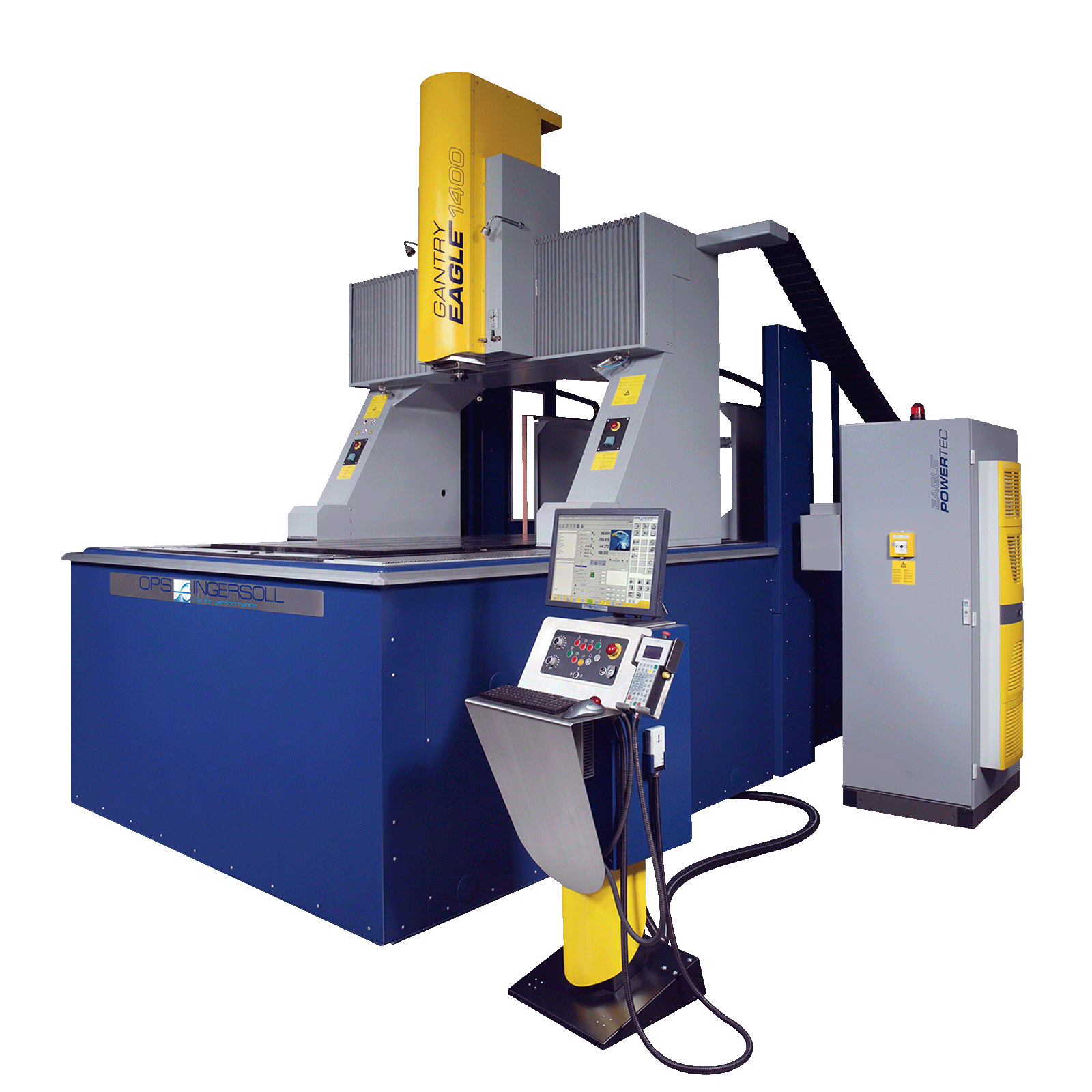

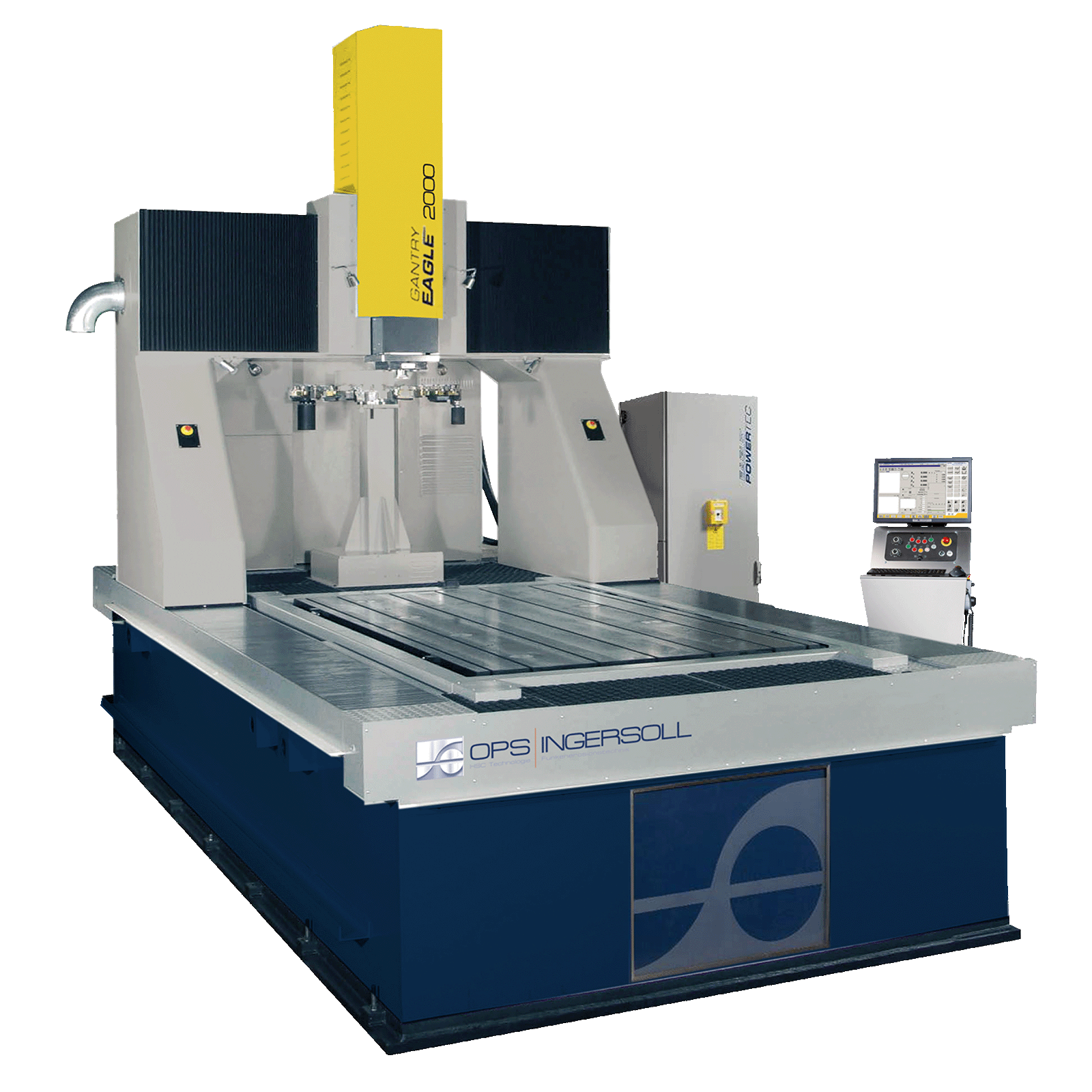

Gantry Eagle 800

Best in class for large part and molding applications – low electrode wear and fast cycle times create an excellent ROI.

Combining the latest in technological innovation with a unique, human-centric design, the Gantry Eagle series places top-quality results firmly within reach—without requiring any extra hassle. Plus, with on-board components designed to reduce wear and tear throughout its lifespan—requiring less maintenance and costly downtime—the Gantry Eagle series offers unmatched utility across any number of projects, materials, industries, and more.

The Gantry Eagle 800 has an unexpectedly large, easy-access working area that requires less floorspace than other sinker EDM models, making it an excellent addition to any operation.

COST-EFFICIENT COMPONENTS

The Eagle PowerTec power supply reduces burn time and electrode wear without sacrificing accuracy.

The Gantry Eagle 800 uses the Eagle PowerTec power supply with the world’s first Adaptive Current-Shape generator. Each discharge pulse calculates and creates the ideal current shape to meet the exact discharge requirements at that moment.

- Eagle PowerTec, combined with Eagle Power Jump, reduces burn time by up to 50% while drastically reducing electrode wear—especially in graphite.

FAST, USER-FRIENDLY OPERATION

The Gantry Eagle 800 features a dual 32-bit, PC-based CNC control that enables faster data processing and servo control. The machine’s unique construction provides thermal stability and rigidity and features a 4-sided drop tank design that allows work-area access from all sides.

UNCOMPROMISING QUALITY

The Eagle Gantry series balances a large workspace with high-precision machining, leading to results your business can comfortably depend on.

CAPABILITIES:

- PT60 PowerTec power supply provides full Adaptive Current-Pulse technology (optional PT110 provides 110 peak AMPs)

- Eagle Power Jump (18m/min.) & Power Jump Plus (3D Jump)

COMPONENTS:

- Fully integrated machine base fluid system

- Fixed table traveling gantry construction

- Direct drive AC smart servo system

- Dual ball screw gantry drive

- 3D lateral servo system

- 4-sided drop tank design

- Easy-access dual filter system

- Dielectric fluid emission

ON-BOARD AUTOMATION:

- Automatic lubrication system

USER INTERFACE:

- Dual 32-bit, PC-based CNC control with 17” touchscreen operation

- Standard USB and Ethernet interface

SYSTEM INFORMATION:

- Windows XP-embedded operating system

- 40GB hard drive

- PowerTec Easy Burn on-board programming

ADDITIONAL BENEFITS:

- Full 2-year warranty with Triple Diamond Partnership Program

| Machine Travels: X x Y x Z in (mm) | 21.6 x 33.5 x 17.7 (550 x 850 x 450) |

|---|---|

| Maximum Workpiece Size: W x D x H in (mm) | 31.5 x 43.3 x 15.7 (800 x 1100 x 400) |

| Max Dielectric Fluid Level: in (mm) | 17.7 (450) |

| Power Supply (Option) / Peak Current | PT60 (PT110) / 80 (110) AMPs |

| Internal Worktank Dimensions W x D x H in (mm) | 31.5 x 43.3 x 18.9 (800 x 110 x 480) |

| Worktank / Door Type | 4-Sided Drop Tank |

| Max. Workpiece Weight: lb (kg) | 4400 (2000) |

| Table Dimensions W x D: in (mm) | 29.9 x 39.4 (760 x 1000) |

| Max. Electrode Weight: lb (kg) | 440 (200) |

| Table to C-Axis Chuck Distance Min ~ Max: in (mm) | 5.3 ~ 23.0 (135 ~ 585) 3R-MACRO Chuck |

| Minimum Command Unit / Resolution: in (mm) | .00001 / .000002 (.0001 / .00005) |

| Rapid Travel Speed: in/min. (mm/min.) | 196.8 (5000) |

| High-Speed Jump Maximum: in/min. (m/min.) | 708 (18) |

| Filters / Type | 2 pc. / Paper Cartridge |

| Filter Tank Capacity: gal (L) | 211 (800) |

| Machine System Dimensions W x D: in (mm) | 96.8 x 106.3 (2460 x 2700) |

| Machine Installed Height: in (mm) | 106.4 (2703) |

| Machine System Weight: lb (kg) | 14,110 (6400) |

| C-Axis Min. Indexing Angle / Drive Unit | .001º / .001º |

| C-Axis RPM Range | 1 ~ 20 Variable |

| Fluid Temp. Control | Chiller Optional |

| Optional Internal Spindle RPM Range | NA |

| Automatic Tool Changer Options | Rotary Disk 20 (30) |

| Power Requirements [KVA] | 400 VAC ±5% [16] without chiller |

| Compressed Air Requirements | 2.7 cu.ft./min @ 90-100 psi |

RELATED SOLUTIONS

-

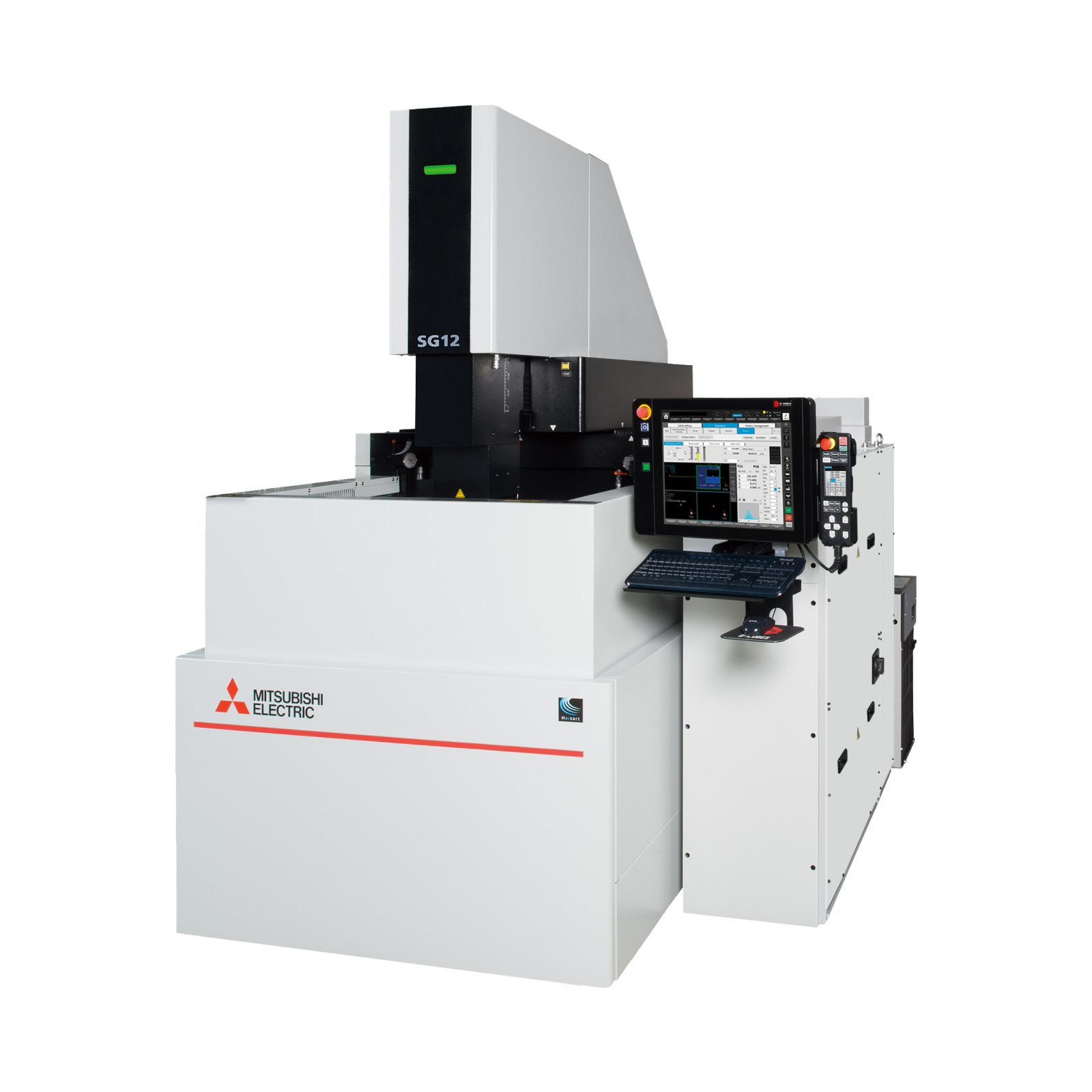

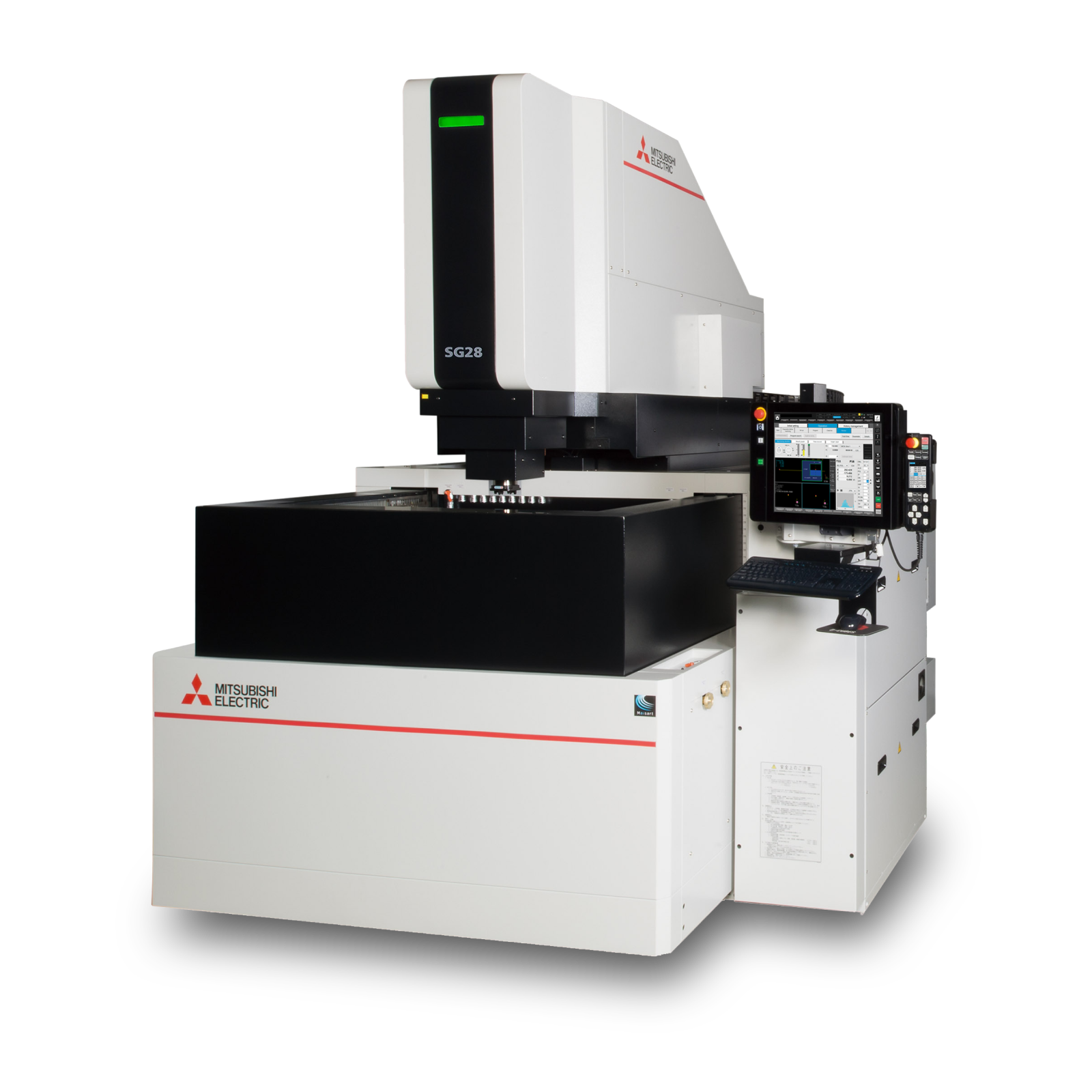

WIRE EDM

Simplifies the process of making parts and obtaining excellent tolerances using minimal manpower.

learn more -

SINKER EDM

Highly repeatable and reliable technology for applications requiring complex shapes, hardened materials, excellent accuracy and consistent surface finishes.

learn more -

EDM AUTOMATION

The ultimate solution to improve throughput, increase production, reduce manpower and be more competitive.

learn more

-

"The biggest thing for me with Mitsubishi EDMs is the accuracy is far superior to other machines I’ve used in the past. Putting a part in the machine, touching off the part, taking it out and it being the right size and location—it’s there all the time."

Adam Hall, Quality Tool & Die EDM operator Read case study -

"The quality and repeatability of Mitsubishi EDMs is second to none."

Aaron Wiegel, President of Wiegel Read case study -

"Overall, the machine itself is just reliable. Out of all the other manufacturers I’ve used over the years, working with Mitsubishi EDM has been one of my best experiences."

Danny Ritchie, head of Wire EDM Department at Dies Plus (a division of OTTO Engineering) Read case study -

"You don’t have to do anything but push a couple of buttons and it goes to mid points, center points–everything you want is right there on the pendant. It makes life simpler. This thing is touch off, write the program, hit the start button and the machine does it for you."

Daryl Bosco, Quality Tool & Die sinker EDM operator Read case study -

"When it comes to applications expertise, it’s a lot more difficult in any industrial OEM to find the breadth and depth that Mitsubishi EDM has."

Jeffrey Taylor, Crafts Technology President and General Manager Read case study