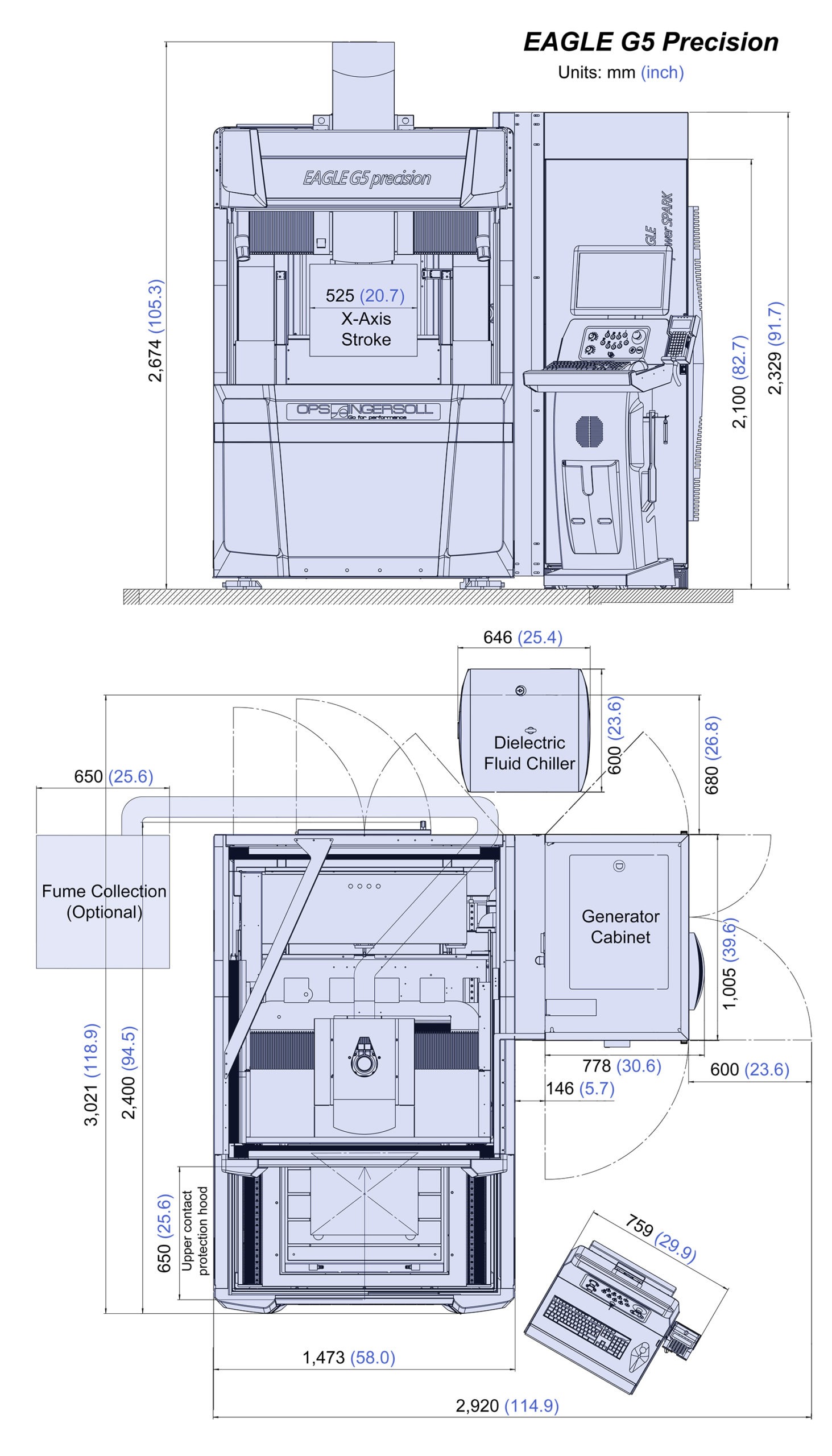

Eagle G5 Precision

For when the utmost in exacting precision is required, the Eagle G5 Precision rises to the challenge.

Manual operation or fully automated? Graphite or copper electrodes? Easy access or easy operation? For those who can’t afford to compromise, the Eagle G5 Precision is a machine designed to be exactly what you need it to be in any situation. Its unique enclosure design allows you to create the most detailed tools possible in a stable, highly accurate environment—but not at the cost of usability or accessibility.

If you’re looking for a machine you can trust to consistently deliver excellence, we’d like to introduce you to the Eagle G5 Precision.

UNMATCHED PERFORMANCE

- The machine delivers optimum results especially in multicavity machining—with incredibly low wear!

- The new Eagle PowerSPARK Generator makes it possible to achieve unique

surface qualities with graphite that no one would have imagined. - The new and fully closed design of the Eagle G5 Precision, in combination with the active temperature control, provides extremely high thermal stability, which is essential

for maximum precision and perfect results—both with graphite and copper electrodes.

EASY TO USE

- The Eagle G5 Precision sports a fully encapsulated design that allows it to achieve such high temperatures and quality, without limiting manual accessibility and full automation capabilities.

- In combination with a new and more powerful drive and control package from

a single source of innovative, user-friendly programming software, the Eagle G5 Precision comes standard with numerous new functions. The Eagle G5 Precision is the prototype of a new generation of EDM machines.

RESULTS YOU’LL NOTICE

- The Eagle G5 Precision is a hit with hundreds of owners and operators, who continue to comment on the unprecedented level of precision and surface quality—all with minimum wear to their machine.

- Cost-effective performance comes built into the Eagle G5 Precision through robust utility, components that wear out less, and results that can meet any quality standard.

CAPABILITIES:

- Maximum precision

- Increased thermal stability

- More than 50% less wear during finishing

- Matte-glossy surfaces with graphite up to VDI 8

- Completely optimized: Generator – Control – Design – Software

- 40% shorter machining times

- Significant reduction of production times

- Active dielectric cooling

- Position and geometric compensation

- Temperature compensation

- Increase of precision and repeatability

| MACHINE | ||

|---|---|---|

| Machine weight | lb. (kg) | 11,795 (5,350) |

| Generator weight | lb. (kg) | 1,411 (640) |

| Power input | kVA | 16 |

| Fuse protection | A | 32 |

| Voltage / Frequency | V/Hz | 400/60 |

| WORK TANK | ||

| Type | Rise and fall tank – filled movable | |

| Clear dimensions (L x W x H) | inch (mm) | 30.3 x 26.4 x 17.3 (770 x 670 x 440) |

| Dielectric fluid level max. programmable/automatic | inch (mm) | 14.7 (375) |

| WORK HEAD | ||

| Max. head load | lb. (kg) | 220 (100) |

| Distance electrode-clamping chuck to work table min./max. | inch (mm) | 5.3/23.0 (135/585)* |

| INTEGRATED C-AXIS | ||

| Rotation Speed (adjustable) | RPM | 1-20 |

| Angle positioning | degree | 0.001 |

| Load capacity for manual electrode change | lb. (kg) | 110 (50)* |

| Load capacity for automatic electrode change | lb. (kg) | 33 (15)* |

| Movement of inertia, max. | lb./ft2 (kg/m2) | 9.5 (0.4)* |

| WORK TABLE | ||

| Surface (L x W) | inch (mm) | 29.5 x 25.6 (750 x 650) |

| Load capacity | lb. (kg) | 2200 (1,000) |

| TRAVEL WAYS | ||

| X / Y / Z inside the work tank | inch (mm) | 20.7 x 15.7 x 17.7 (525 x 400 x 450) |

| Y (by electrode changing position) | inch (mm) | 26.6 (675) |

| CONTROL EAGLE PowerSPARK One | ||

| HMI | OS | Windows® 7 ultimate |

| Type of drive | digital AC-servo | Direct-drive Ball screw |

| X, Y, Z rapid traverse | inch/min. (mm/min.) | 197 (5,000) |

| Power Jump Z max. | inch/min. (mm/min.) | 708 (18,000) |

| Power Jump Plus X,Y (option) | inch/min. (mm/min.) | 197 (5,000) |

| DIELECTRIC SUPPLY | ||

| Filter system | Cartridge (integrated) | |

| Filter surface area | sq.ft. (m2) | 172 (16) |

| Dielectric fluid, total volume | gal. (ltr.) | 106 (400) |

| ELECTRODE CHANGER | ||

| Type (option) | Direct pick-up rotary disc | |

| Positions (option) | 20 (30) | |

| Electrode weight | ||

| – Single electrode | lb. (kg) | 33 (15)* |

| – Total weight | lb. (kg) | 132 (60)* |

| GENERATOR | ||

| Type (Option) | PT60 (PT110) | Adaptive current |

| Machining power, max. (option) | A | 60 (110) |

| ADDITIONAL FEATURES | ||

| Automatic lubrication | Standard | |

| Chiller, cooling power | kW | 3.9 |

| CO2-fire extinguisher, DIN 14497, size | lb. (kg) | 13 (6) |

Note:

The indicated values are maximum values that can be lower depending on the selected clamping system.

We reserve the right to make technical changes.

RELATED SOLUTIONS

-

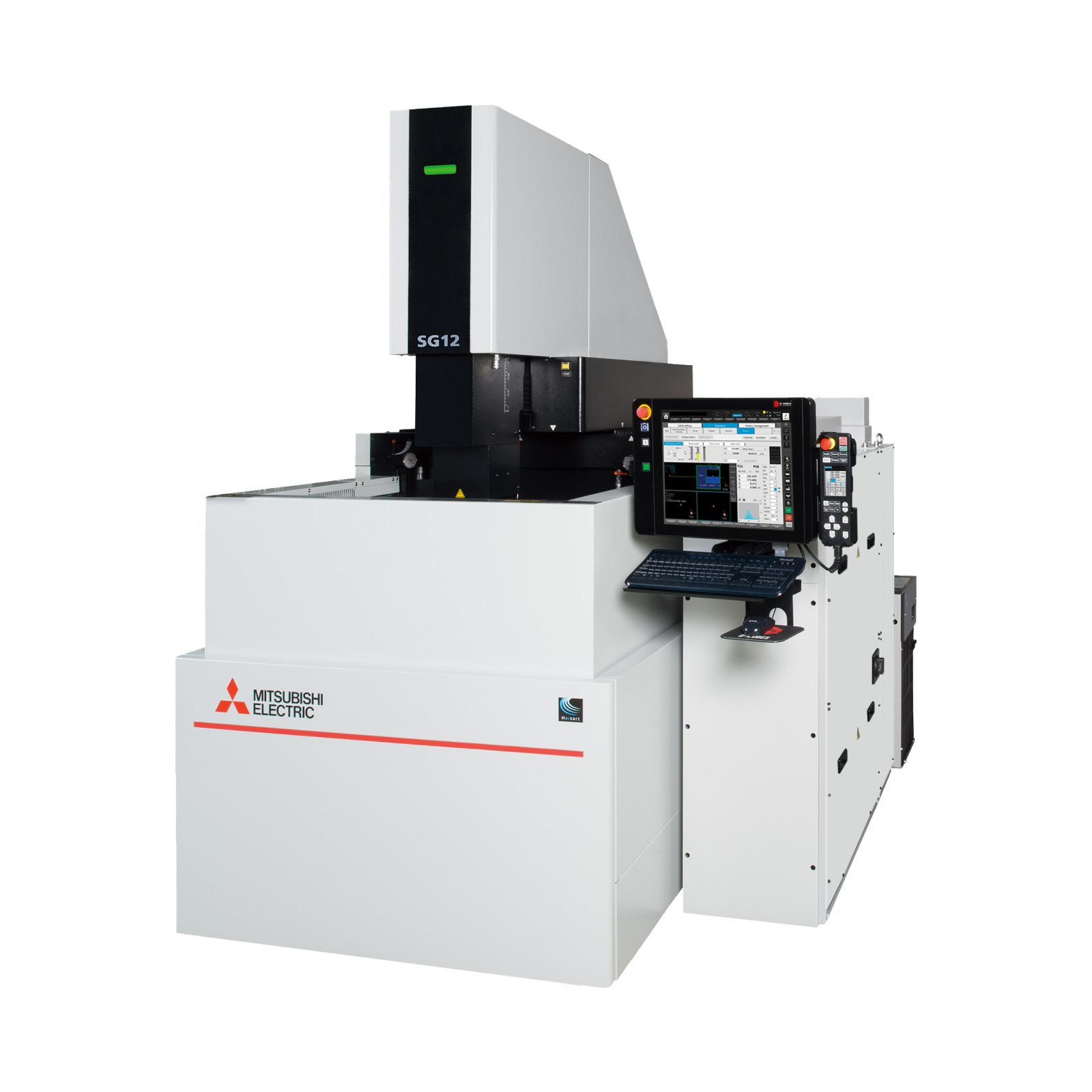

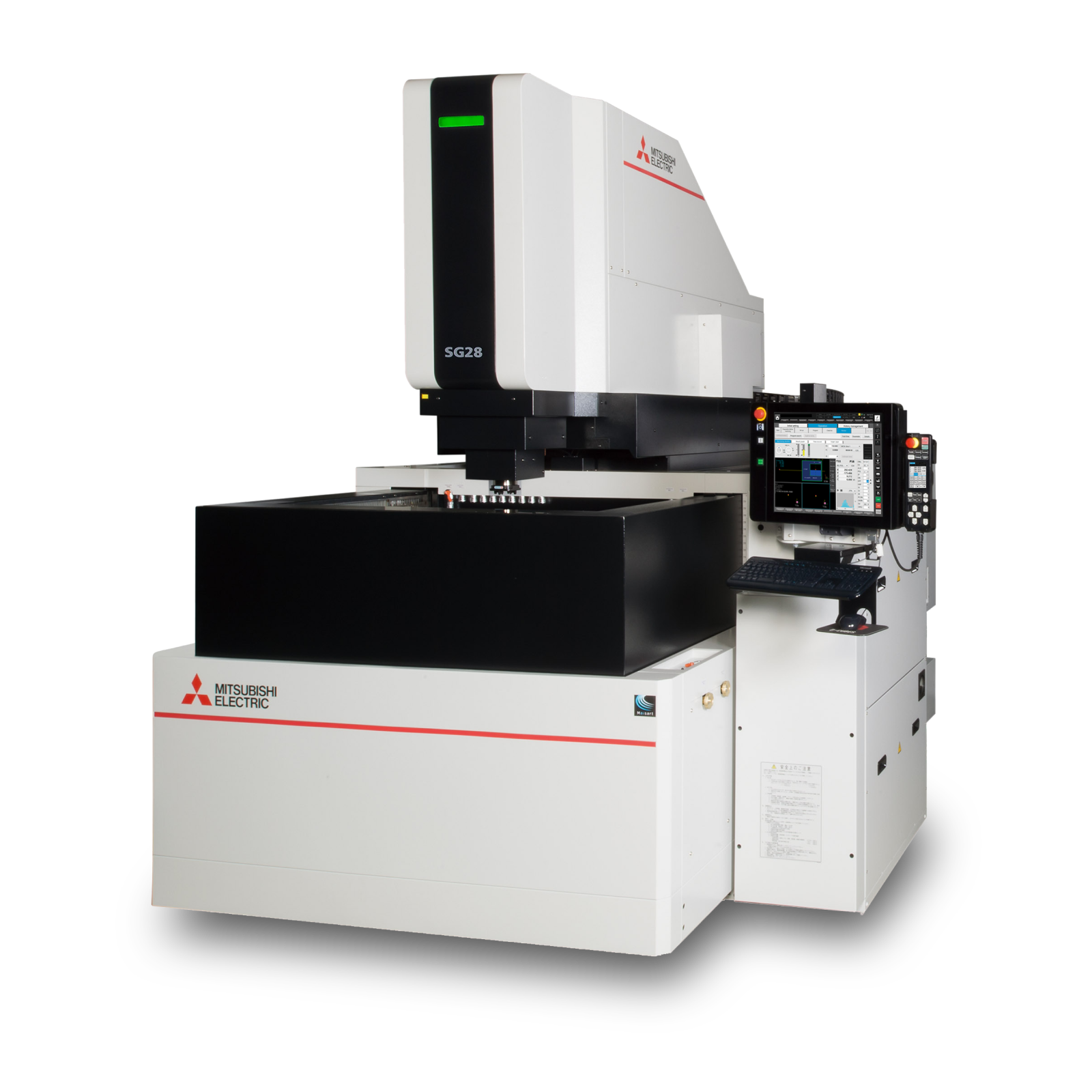

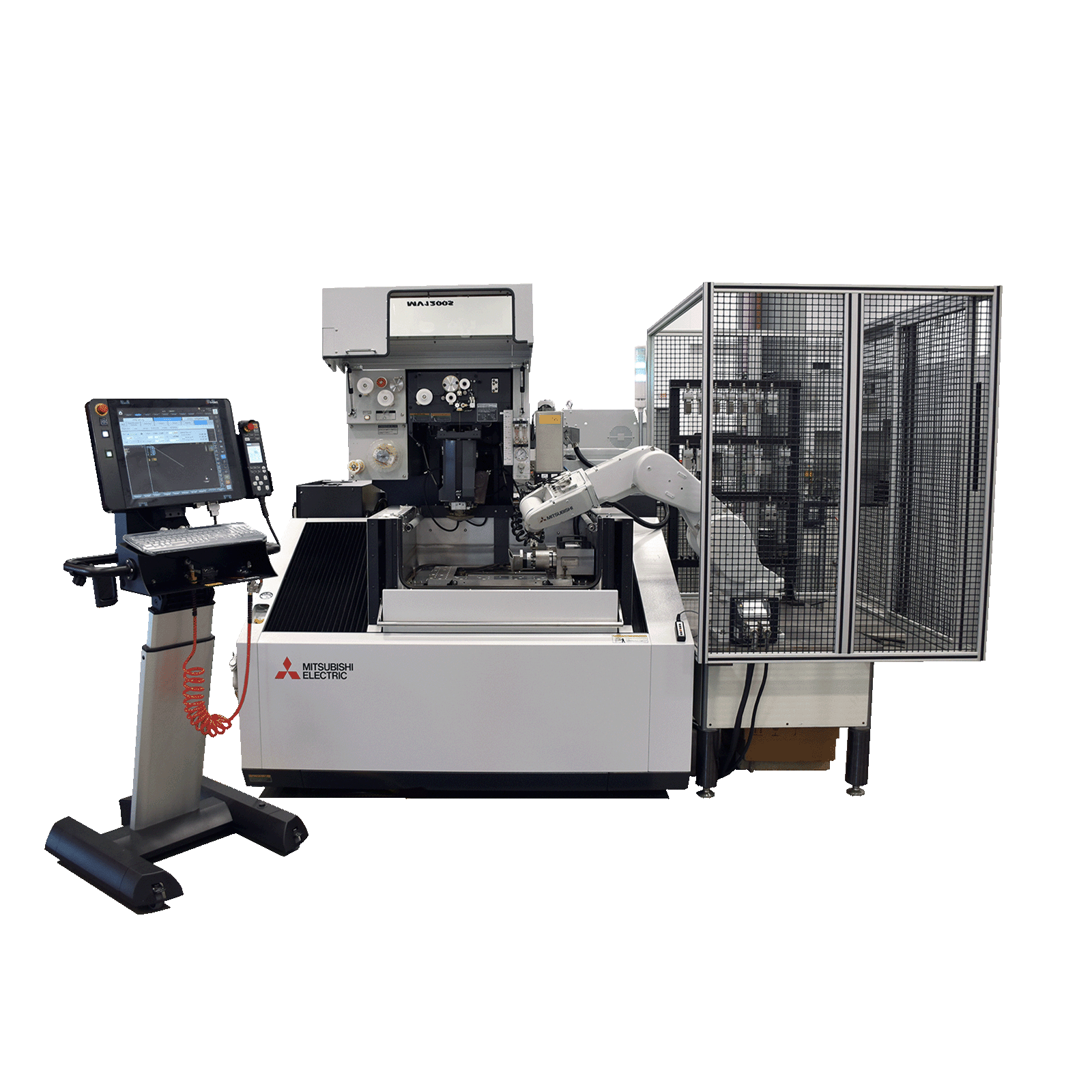

WIRE EDM

Simplifies the process of making parts and obtaining excellent tolerances using minimal manpower.

learn more -

SINKER EDM

Highly repeatable and reliable technology for applications requiring complex shapes, hardened materials, excellent accuracy and consistent surface finishes.

learn more -

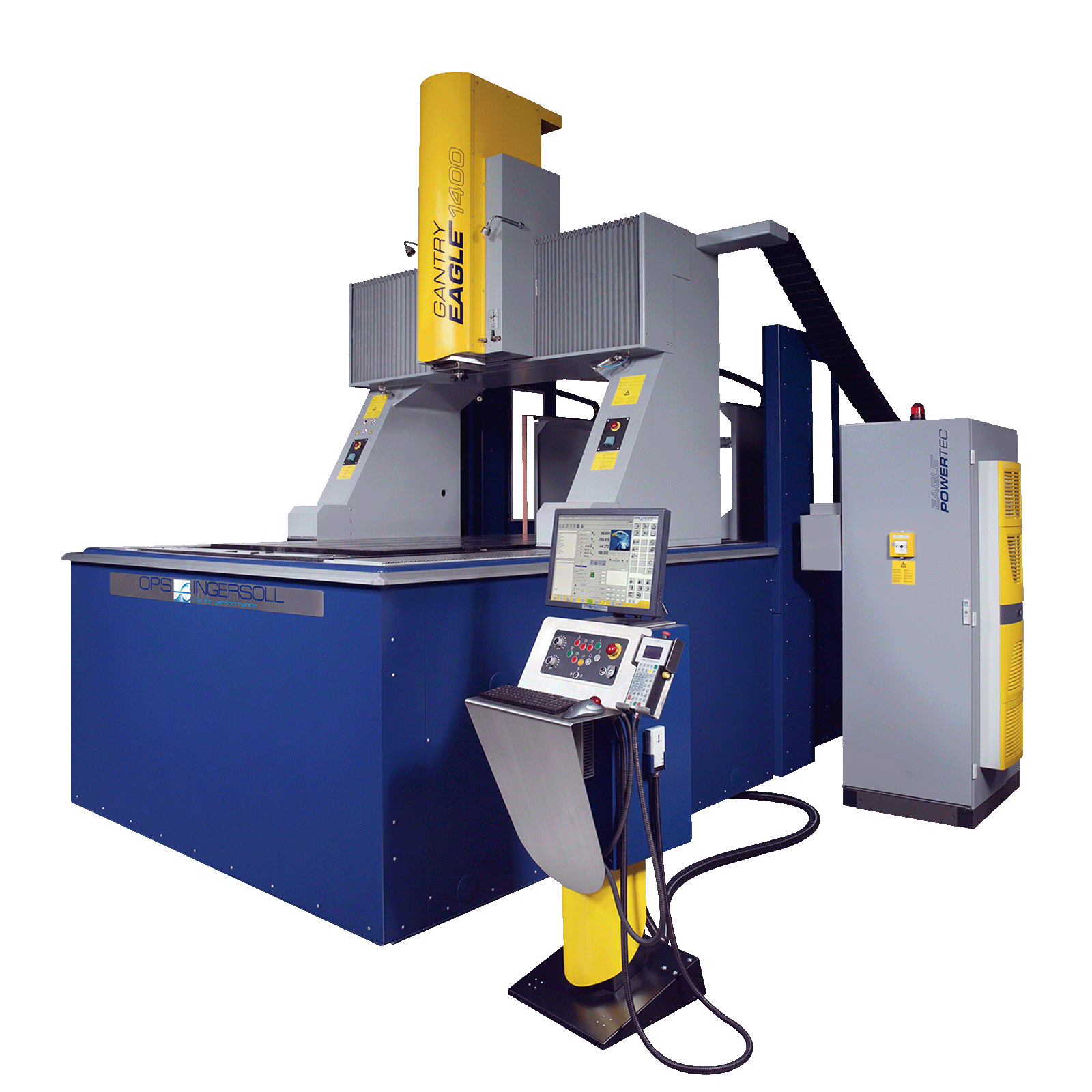

EDM AUTOMATION

The ultimate solution to improve throughput, increase production, reduce manpower and be more competitive.

learn more

-

"The biggest thing for me with Mitsubishi EDMs is the accuracy is far superior to other machines I’ve used in the past. Putting a part in the machine, touching off the part, taking it out and it being the right size and location—it’s there all the time."

Adam Hall, Quality Tool & Die EDM operator Read case study -

"The quality and repeatability of Mitsubishi EDMs is second to none."

Aaron Wiegel, President of Wiegel Read case study -

"Overall, the machine itself is just reliable. Out of all the other manufacturers I’ve used over the years, working with Mitsubishi EDM has been one of my best experiences."

Danny Ritchie, head of Wire EDM Department at Dies Plus (a division of OTTO Engineering) Read case study -

"You don’t have to do anything but push a couple of buttons and it goes to mid points, center points–everything you want is right there on the pendant. It makes life simpler. This thing is touch off, write the program, hit the start button and the machine does it for you."

Daryl Bosco, Quality Tool & Die sinker EDM operator Read case study -

"When it comes to applications expertise, it’s a lot more difficult in any industrial OEM to find the breadth and depth that Mitsubishi EDM has."

Jeffrey Taylor, Crafts Technology President and General Manager Read case study