MEGA SSS-400/600 5AXP (5-AXIS)

The high-accuracy, high-precision fusion of 5 axis technology for your micro-fine milling and small-hole drilling needs.

When the job calls for high-precision cutting, you use a 5-axis milling machine. But sometimes there are other factors to consider, and not all 5-axis milling machines are created equal. For some projects—the kind that require fast, accurate results down to the 1,000th of a millimeter—you need a machine that’s up to the task.

The MEGA SSS family of 5-axis machining centers combine high-speed machining (40,000 and 60,000 RPM via the 400 and 600 versions, respectively) with micro-fine detailing capabilities, allowing your shop to reliably tackle small-hole drilling, micro-accuracy machining, and more.

Come see what a difference a true hybrid milling machine can make—for your customers, your shop, and you.

MICRO-FINE MACHINING, MAXIMUM EFFICIENCY

- By delivering high-accuracy cuts quickly, the MEGA SSS-400/600 5AXP makes you more productive, allowing you greater control over your business.

RUNS FAST, BUILT TO LAST

- The MEGA SSS-400/600 5AXP combines rugged construction materials and dynamic internal components to enable continuous operation at max speed—without compromising quality.

BRING BALANCE TO YOUR SHOP FLOOR

- By offering multiple milling capabilities all in one single machine, the MEGA SSS-400/600 5AXP lets you handle more than ever before—backed up by best-in-class support from our responsive service teams.

CAPABILITIES:

- Ideal for both small-hole drilling and micro-fine 5-axis milling through its unique “super hybrid” design

- Allows simultaneous 5-axis control with a special design for optical encoder feedback on the rotary unit

- Wide speed range (3,000 through 40,000 RPM for the 400), (3,000 through 60,000 RPM for the 600) via an oil-mist lubricated spindle and a long-life AC motor

- Capable of 5-second tool changes, thanks to 20-position twin arm-style tool changer

- Provides both high-precision 3-axis positioning and additional 2-axis indexing accuracy

- Operates across a wide speed range via an oil-mist lubricated spindle and a long-life AC motor

- Provides excellent shock and vibration dampening for high-speed, high-precision machining and greater stability via high-rigidity structure and Meehanite GC castings for both the base and bridge

- Built to jig-grinder standards of quality and accuracy with bridge construction that eliminates the X axis table overhang commonly associated with C-frame construction designs

- New tool measurement device location “Blum Laser” is relocated to an out-of-stroke position

- A pneumatic counterbalance is located on the spindle headstock providing smooth, accurate movement of the Z axis during high-velocity contouring and drilling

- Features an increased portal height (7.9”/200mm) for addition of the A/C axis unit

COMPONENTS:

- High-rigidity Meehanite structure

- High-rigidity HSK-E40 tool holders, allowing 6x higher clamping force than a regular BT shank for highly reliable work

- Roller pack-type linear motion ways

- Z axis thermal growth compensation

- Non-contact tool measurement (Blum Laser) with air-blow cleaning

- Dual Z axis balance cylinders

- X, Y, Z axis linear scales

- Spindle chiller with 7-gallon oil tank

- 80-gallon coolant tank standard

USER INTERFACE:

- Fanuc 31i-B5 super high-speed processing, NANO smoothing, AI Contour Control II, and NANO interpolation

- 1000-block look-ahead block expansion

- Super PC III function with 3-mode operation to balance speed and accuracy

| Machine Travels: X x Y x Z in (mm) | 16.0 x 13.0 x 7.9 (400 x 330 x 200) |

|---|---|

| Spindle Speed (600) | 3,000 ~ 40,000 RPM (60,000 RPM) |

| Spindle HP | 4.7 |

| Spindle Lubrication | Oil Mist |

| Tool Changer Size | 20 Position Standard (40 or 60 optional) |

| Positioning Accuracy/Repeatability: in (μm) | ±0.000040/±0.000012 (±1.0/±0.3) |

| Rotary Table Faceplate: in (mm) | Ø 3.94 (Ø100) |

| Max. Tilting A-Axis Angle: deg. | -120 ~ +10 |

| Rotary C-Axis Index Accuracy | ±1.5 arc sec. |

| Tilting A-Axis Index Accuracy | ± 3.5 arc sec. |

| Faceplate to Spindle Nose Distance: in (mm) | 1.07 ~ 8.94 (27 ~ 227) |

| Max. Workpiece Weight: lb (kg) | 20 (44) |

| Coolant Tank Capacity: gal (L) | 37 (140) |

| Faceplate Height from Floor: in (mm) | 38.3 (973) |

| Actual Measured Circularity (2.0″ dia. @8 IPM): in (μm) | 0.000039 (1.0) |

| Spindle Taper | HSK-E25 |

| Spindle Air Purge | Standard |

| Air Blast through Spindle | NA |

| Oil Mist with Collector | Optional |

| Linear Scales X, Y, Z – axes | Heidenhain 0.000002mm Standard |

| Rapid Traverse Speed: in/min. (m/min.) | 590 (15.0) |

| Cutting Speed (Normal Mode): in/min. (mm/min.) | 0.04 – 394 (1 ~ 10,000) |

| Cutting Speed (GR Super PC Mode): in/min. (m/min.) | 590 (1.5) |

| Dust Collection System | NA |

| Machine Weight: lb (kg) | 6173 (2800) |

| Machine Height: in (mm) | 90.1 (2290) |

| Required Floor Space: in (mm) | 79.1 x 106.0 (2010 x 2690) w coolant chiller option |

| Control Unit | Fanuc 31i-B5 Super High-Speed Processor, Al Contour Control II and 5-Axis machining package |

| Power Requirements KVA | 200 ~ 220VAC: 14.0KVA (16.5kVA w options) |

| Air Supply | 9 cu.ft./min @ 72 psi |

RELATED SOLUTIONS

-

5-AXIS MACHINING TECHNOLOGY

High-speed, high-precision machines with the power and flexibility to meet any challenge.

learn more -

LINEAR DRIVE TECHNOLOGY

Hyper-accurate machinability for tight tolerances and micro-fine work where the details really matter.

learn more -

HIGH SPEED MACHINING

Top-of-the-line machinery with added cooling power for consistent performance on mission-critical tasks.

learn more -

GRAPHITE MANUFACTURING

Multiple solutions and expertise in making graphite electrodes.

learn more -

MILLING AUTOMATION

Multiple solutions and expertise in making graphite electrodes.

learn more

-

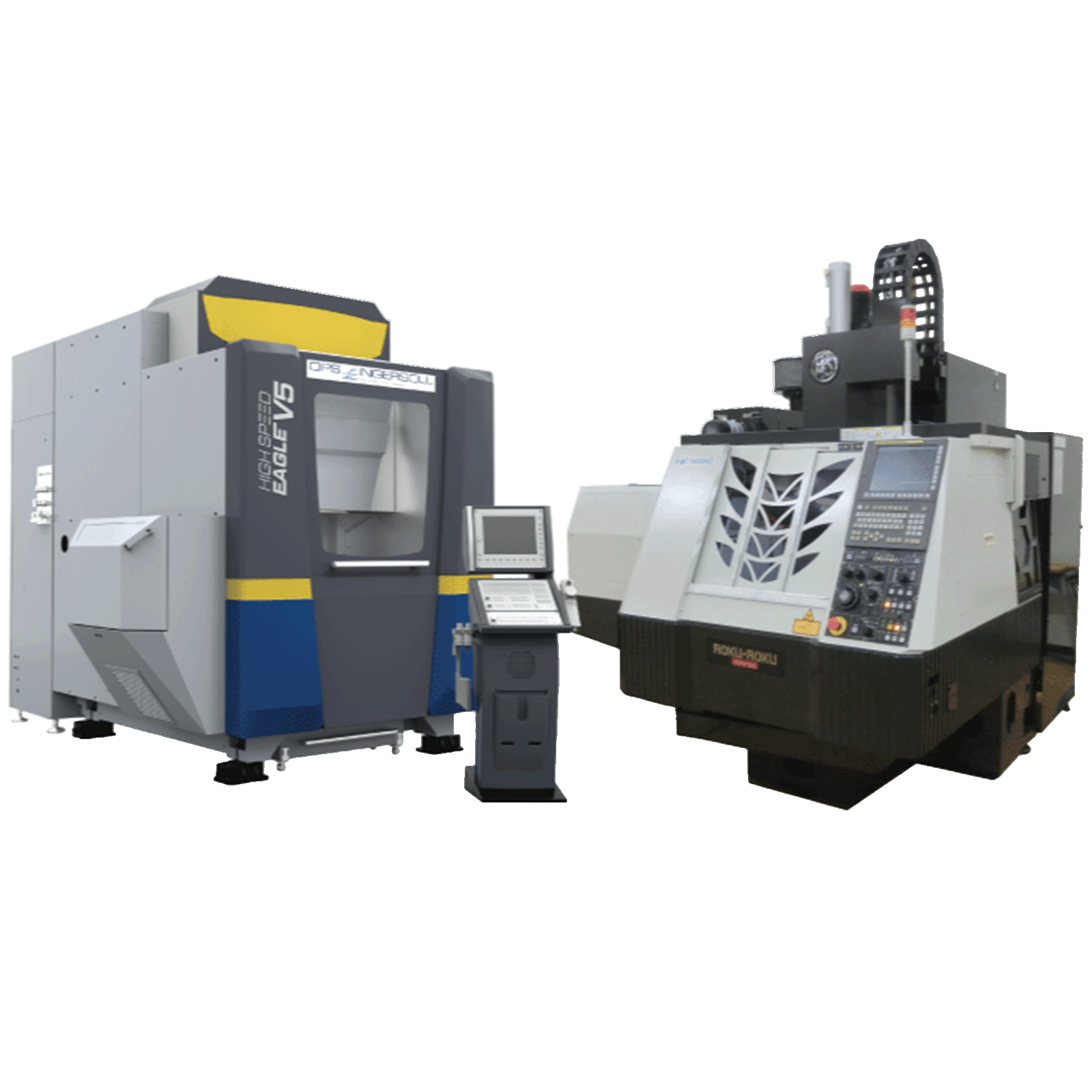

"Not only does the 5-axis capability of the OPS Ingersoll Eagle V5 milling machine enable us to burn parts with less physical electrodes, it also has a robotic tool changer so we can focus more during the day on things that need constant attention."

Brad McDowell, Quality Tool & Die president Read case study -

"The OPS Ingersoll 5-axis milling machines are fast, accurate, easy to operate and have a small footprint."

Bill Yakle, Owner of Aisling Industries learn more -

"The Eagle 800 has burn technology that gives us a competitive advantage because it takes about half the time to burn and uses fewer electrodes, which saves both time and money. Our goal is to run it all day and all weekend. I like that we also are cutting down on our carbon footprint by using fewer graphite electrodes and less copper wire than before."

Steve Michon, President at Zero Tolerance view case study -

"We used to struggle with tool deflection on deep cuts. Now we’re able to tip that up in a five axis and actually hit on the bottom of the flute. And we’re not getting that tool push anymore. Electrodes are so, so much more accurate."

Chad Kearns, Quality Tool & Die vice president Read case study -

"Our biggest supply chain issue is labor, but we have been able to achieve lights-out operation by adding the MC Machinery equipment. We have kept costs down while improving accuracy and doing more with the same number of employees."

Todd Doerfert, Operations Manager at Mantz Automation learn more -

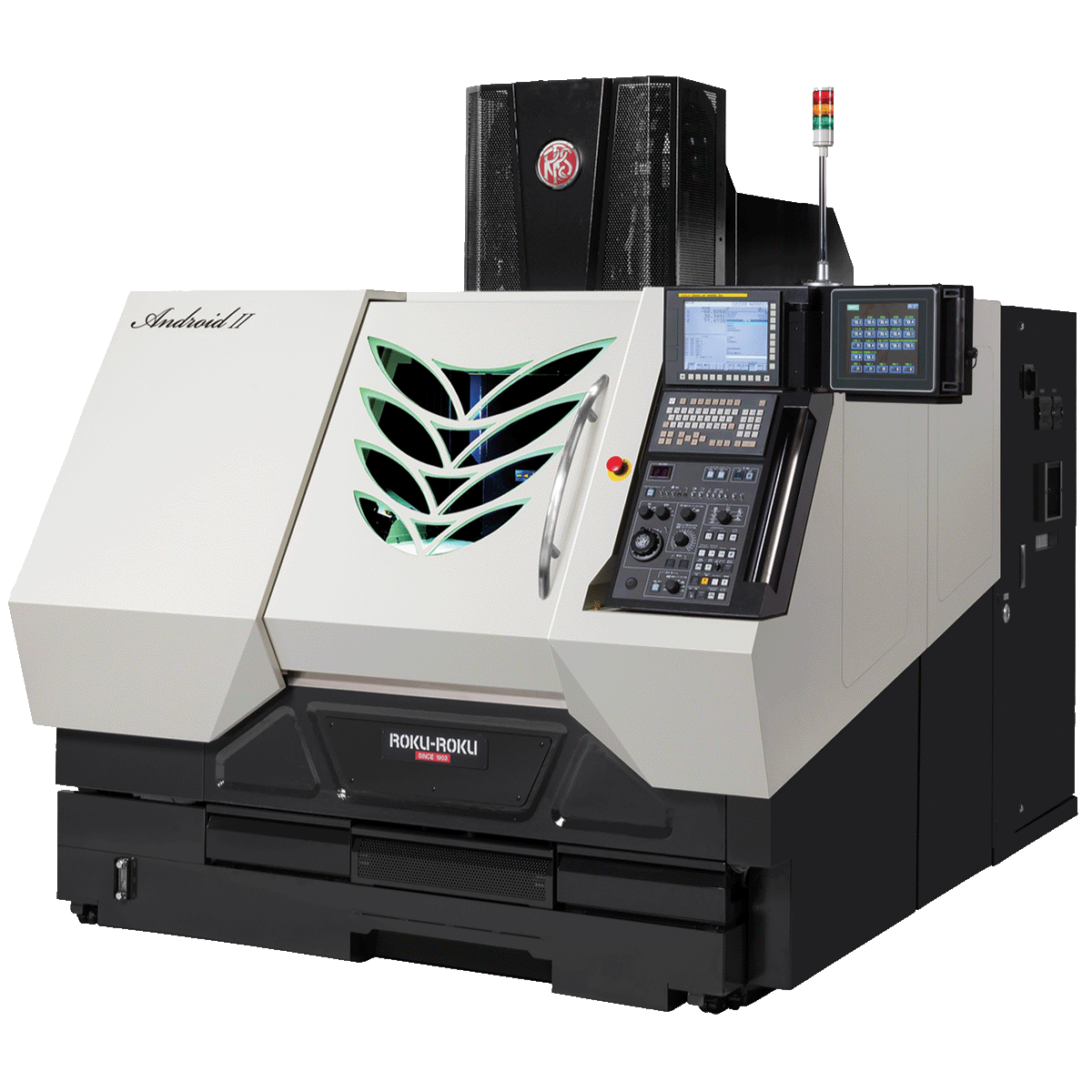

"The kinematics of the Roku-Roku VMCs allow us to run faster feed rates and not sacrifice surface finish or accuracy. The machines are efficient in terms of increased cutter life, reliable Fanuc control and overall machine stability. We can run longer intervals on downstream inspection on parts that the Roku-Rokus machined."

John TerBeek, Co-Owner at TerBeek Molding & Tool view case study