SG70 Sinker EDM

- Large work envelope for oversized molds and deep features (59″ x 43.3″ tank; 39.3″ × 27.5″ × 19.6″ travels).

- Reduced electrode wear with IDPM3, optimizing spark energy automatically for graphite and copper electrodes.

- Up to 40% faster jump speed with SS Jump 5, enabling high-speed NO-FLUSH machining and shorter cycle times.

- Ultra-stable accuracy with thermal displacement compensation that monitors environmental changes in real time.

- High-speed positioning (157 in/min) for efficient setup and dry run checks.

- 19″ intuitive touchscreen with M800 control for simplified operation and programming.

- ESPER II Navigator reduces programming time with guided Q&A workflow—ideal for operators of all experience levels.

- Heavy workpiece capability (up to 6,614 lbs) for large molds and high-mass tooling.

- Massive dielectric system (343 gal reservoir, chiller included) for stable long-duration burning.

RELATED SOLUTIONS

-

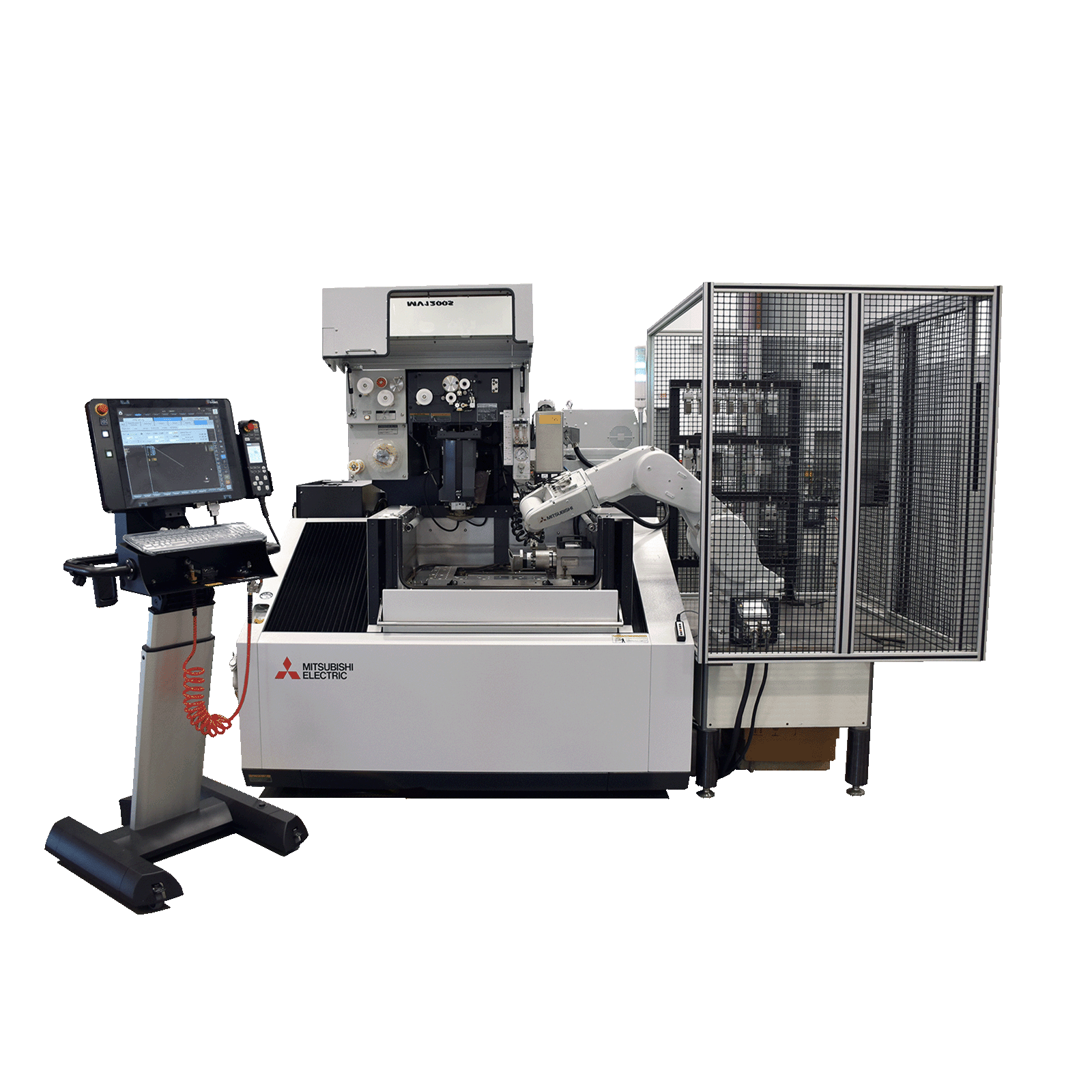

WIRE EDM

Simplifies the process of making parts and obtaining excellent tolerances using minimal manpower.

learn more -

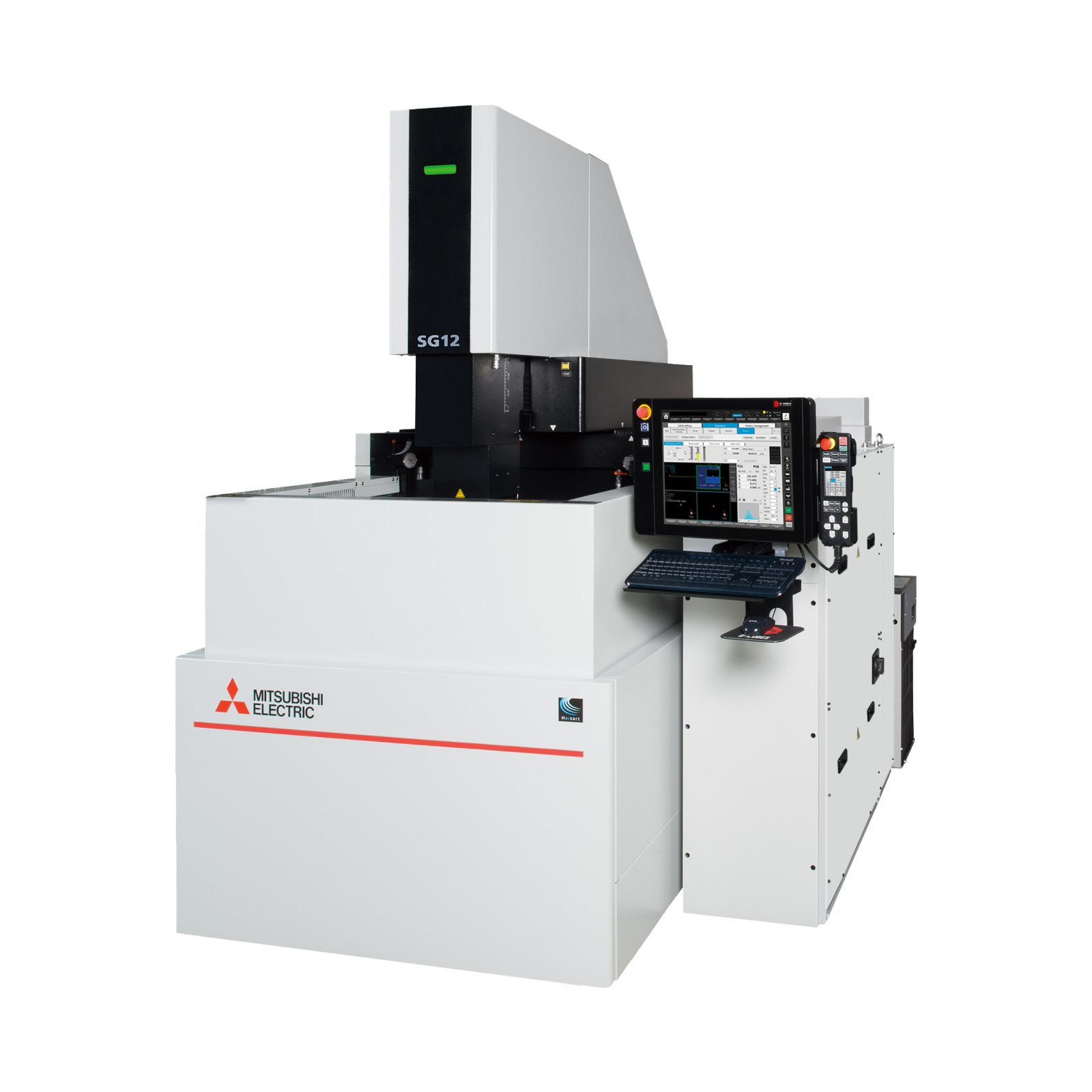

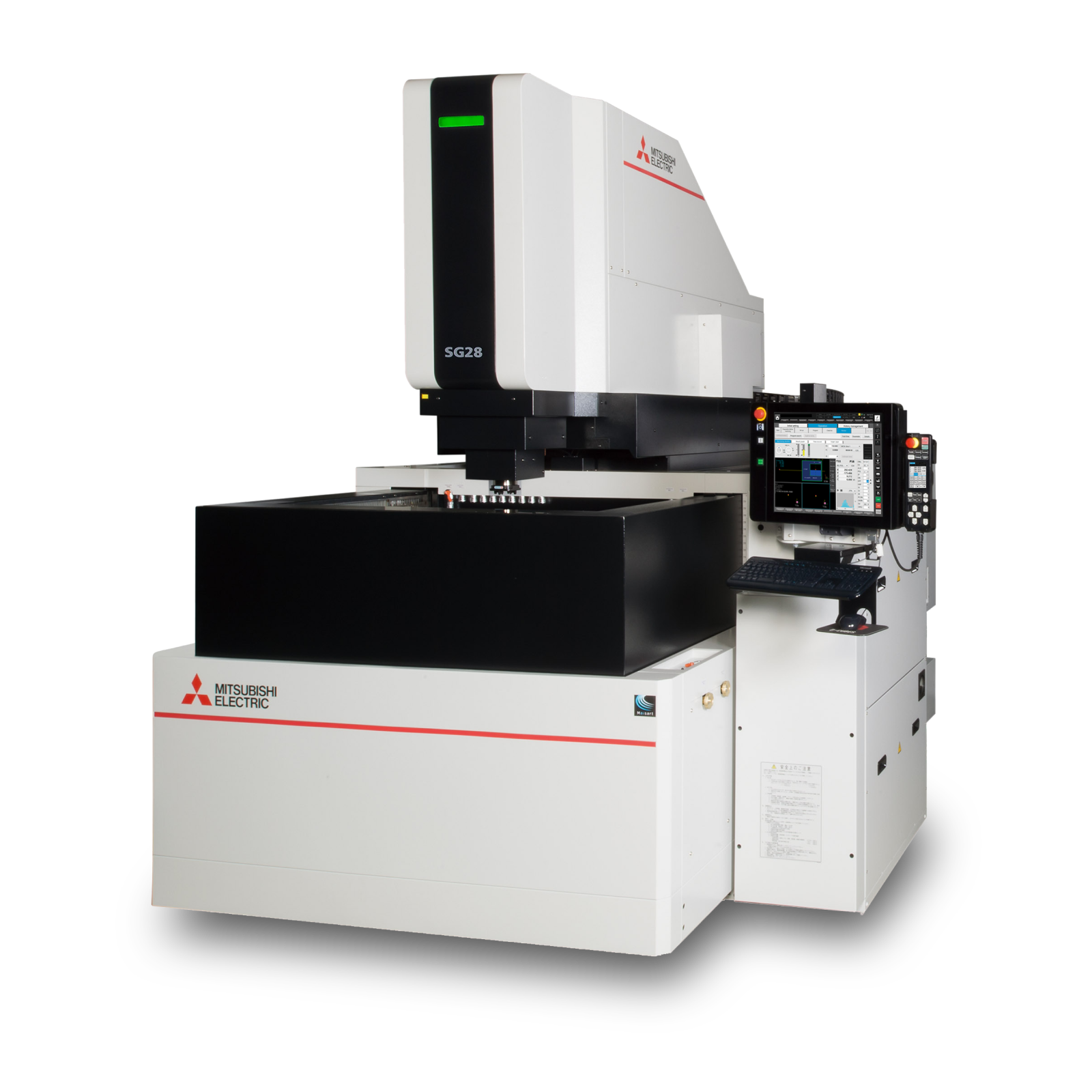

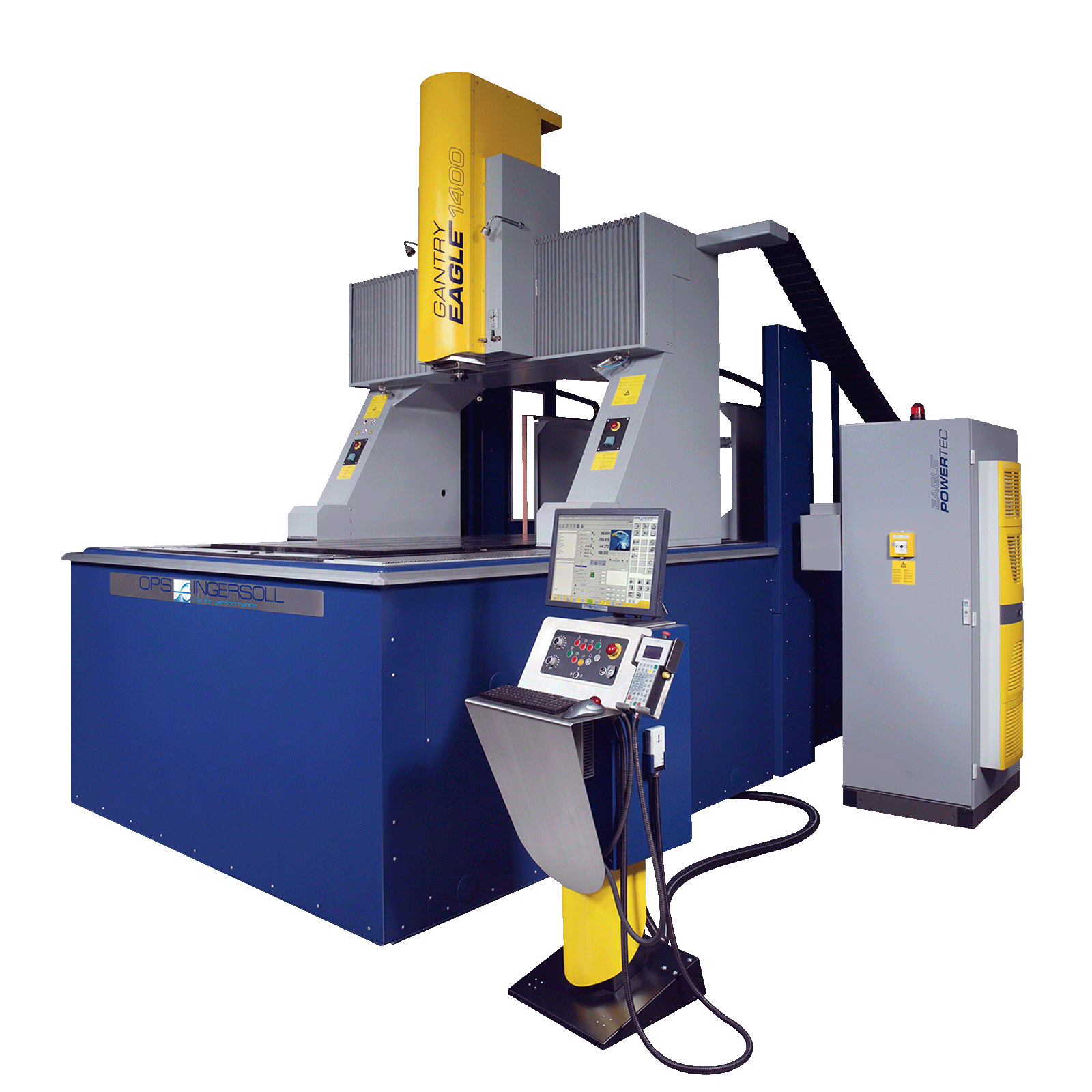

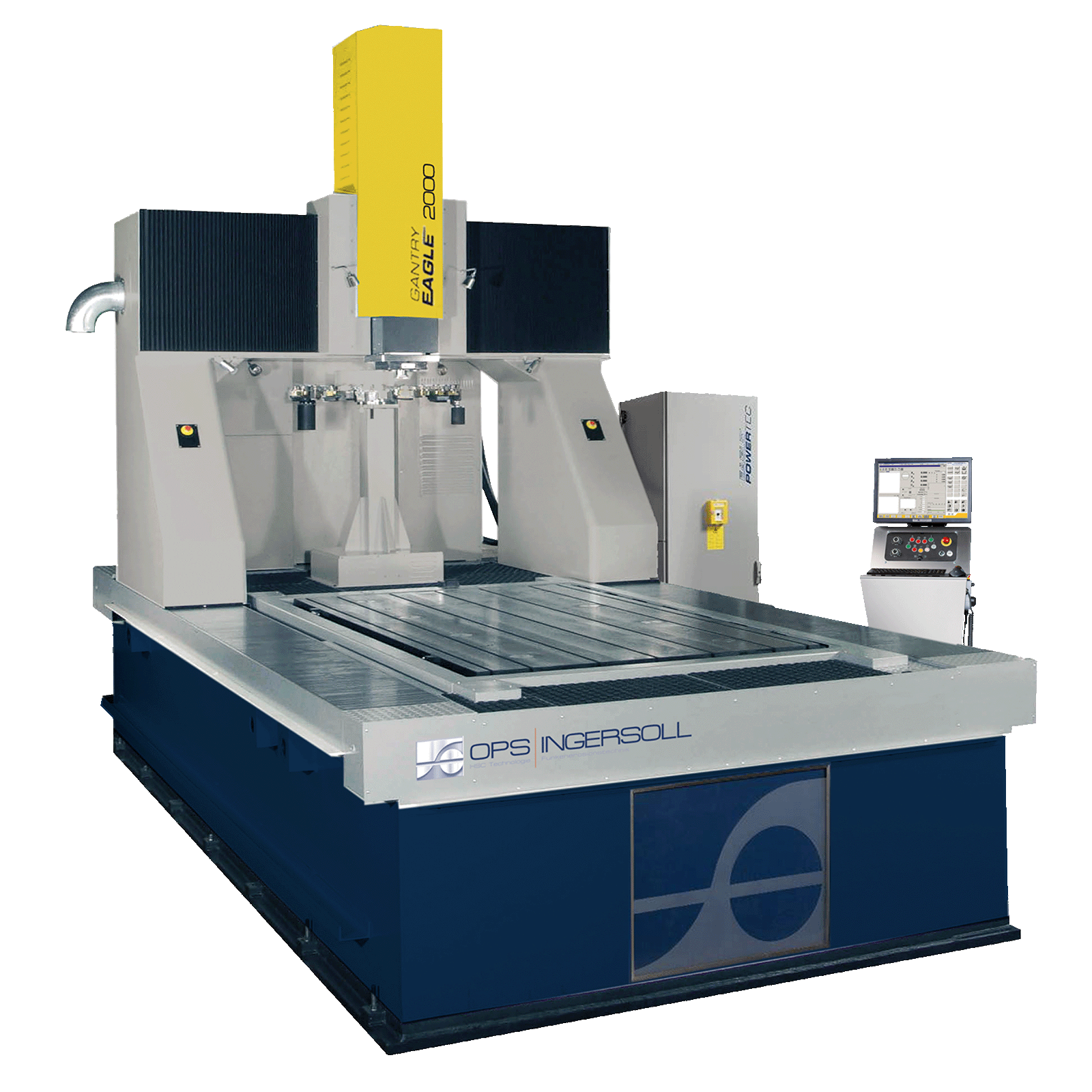

SINKER EDM

Highly repeatable and reliable technology for applications requiring complex shapes, hardened materials, excellent accuracy and consistent surface finishes.

learn more -

EDM AUTOMATION

The ultimate solution to improve throughput, increase production, reduce manpower and be more competitive.

learn more

-

"The biggest thing for me with Mitsubishi EDMs is the accuracy is far superior to other machines I’ve used in the past. Putting a part in the machine, touching off the part, taking it out and it being the right size and location—it’s there all the time."

Adam Hall, Quality Tool & Die EDM operator Read case study -

"The quality and repeatability of Mitsubishi EDMs is second to none."

Aaron Wiegel, President of Wiegel Read case study -

"Overall, the machine itself is just reliable. Out of all the other manufacturers I’ve used over the years, working with Mitsubishi EDM has been one of my best experiences."

Danny Ritchie, head of Wire EDM Department at Dies Plus (a division of OTTO Engineering) Read case study -

"You don’t have to do anything but push a couple of buttons and it goes to mid points, center points–everything you want is right there on the pendant. It makes life simpler. This thing is touch off, write the program, hit the start button and the machine does it for you."

Daryl Bosco, Quality Tool & Die sinker EDM operator Read case study -

"When it comes to applications expertise, it’s a lot more difficult in any industrial OEM to find the breadth and depth that Mitsubishi EDM has."

Jeffrey Taylor, Crafts Technology President and General Manager Read case study -

"Tooling for high-speed stamping has some tight tolerances, but the Mitsubishi wire EDMs have no problems meeting those tolerances. To know what we’re getting out of those machines on a consistent basis is huge for us."

Keith Dombrowski, Dies Plus Wire EDM Supervisor Read case study