Keep your day-to-day operations running smoothly with relevant machine insights.

LEARN MOREWhere detailed, efficient metal removal is difficult or impossible to do accurately by conventional means, electrical discharge machining (EDM) is the practical choice.It’s predictable, accurate, and repeatable.

But when it comes to delivering quality at scale, cutting timelines without cutting corners, and making quick work of high-tolerance jobs, you’ll need an advantage over typical EDM solutions. And that’s where we come in.

If you’re machining small, tight-tolerance items where accuracy is key—like in aerospace and medical segments—you and your workers need a reliable, cost-and resource-efficientsolution that’s easy to use andeasy to trust.

Keep your day-to-day operations running smoothly with relevant machine insights.

LEARN MORE

Introducing the Next-Generation SG8 Sinker EDM with Mitsubishi Electrics’s AI Technology (Maisart) and M800 Series Control System to pursue both…

LEARN MORE

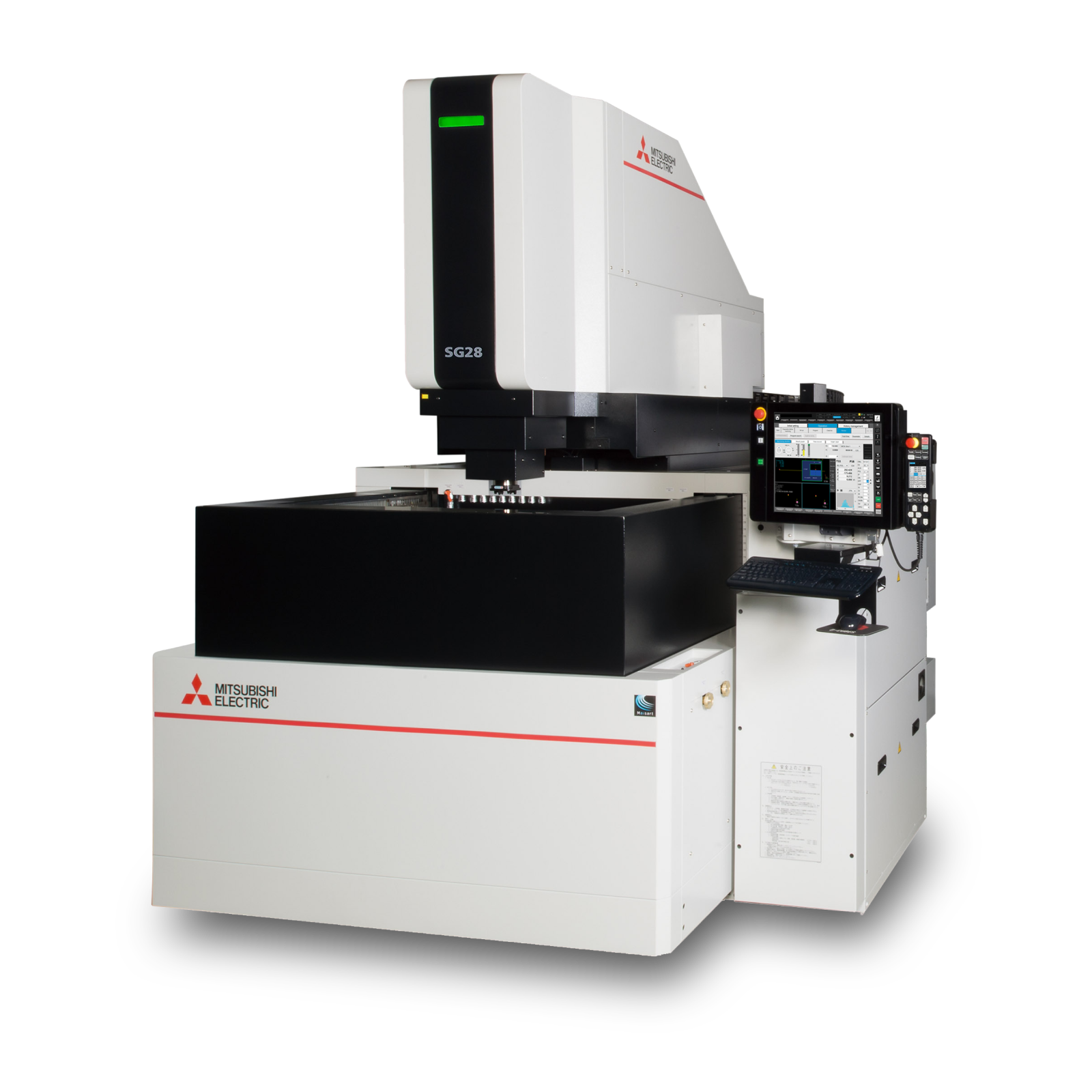

Introducing the Next-Generation SG28 Sinker EDM with Mitsubishi Electrics’s AI Technology (Maisart) and M800 Series Control System to pursue both…

LEARN MORE

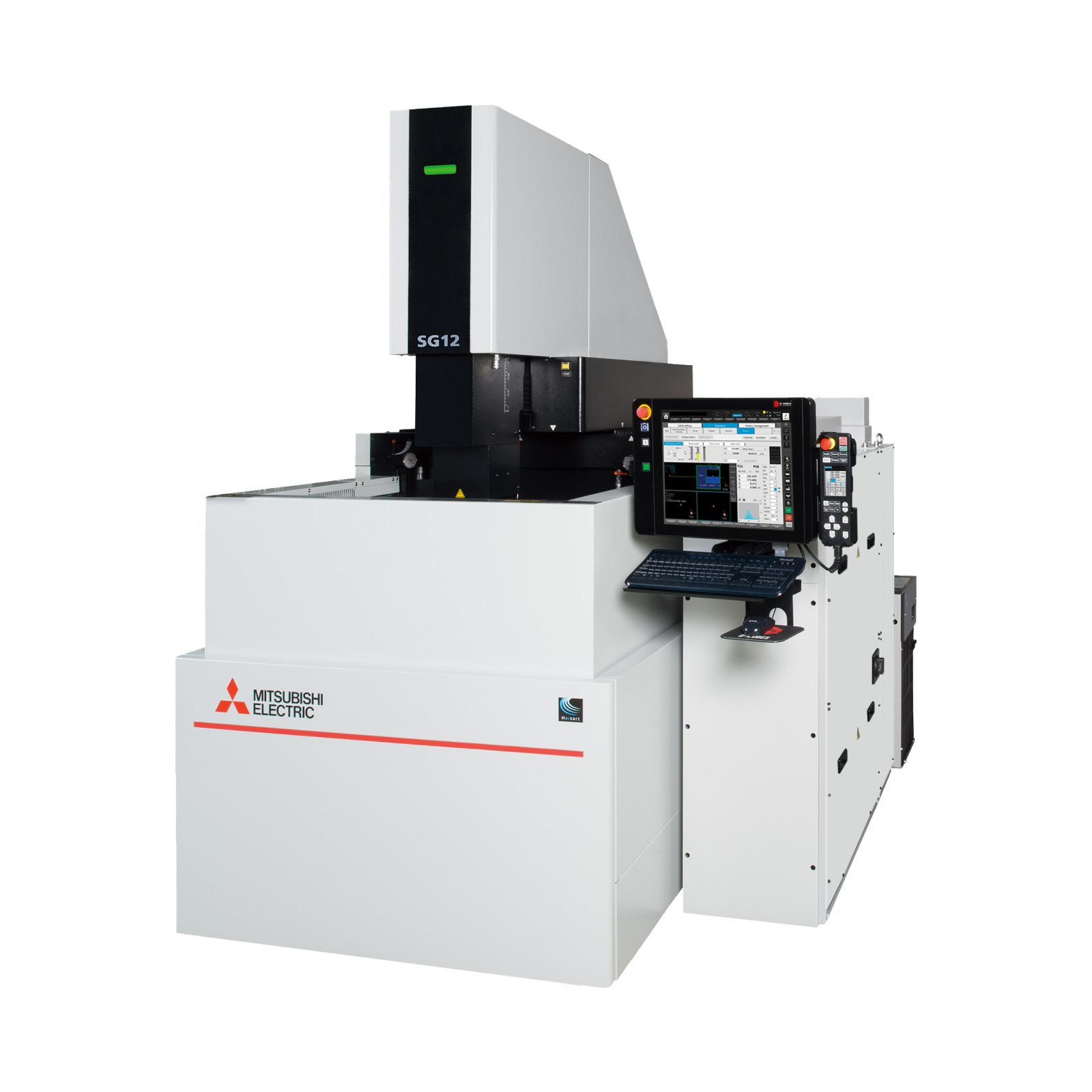

Introducing the Next-Generation SG12 Sinker EDM with Mitsubishi Electrics’s AI Technology (Maisart) and M800 Series Control System to pursue both…

LEARN MORE

An artificial intelligence-infused powerhouse that brings serious smarts to tight-tolerance machining.

LEARN MORE

An AI-infused powerhouse that brings serious smarts to tight-tolerance machining.

LEARN MORE

With a larger-than-standard working tank for larger and taller parts, the EA28V-LS lets you accomplish even more.

LEARN MORE

An AI-infused powerhouse that brings serious smarts to tight-tolerance machining.

LEARN MORE

Best in class for large part and molding applications – low electrode wear and fast cycle times create an excellent…

LEARN MORE

A larger work area, reliable performance, low electrode wear, and fast cycle times create the best value in the industry.

LEARN MORE

For when the utmost in exacting precision is required, the Eagle G5 Precision rises to the challenge.

LEARN MORE

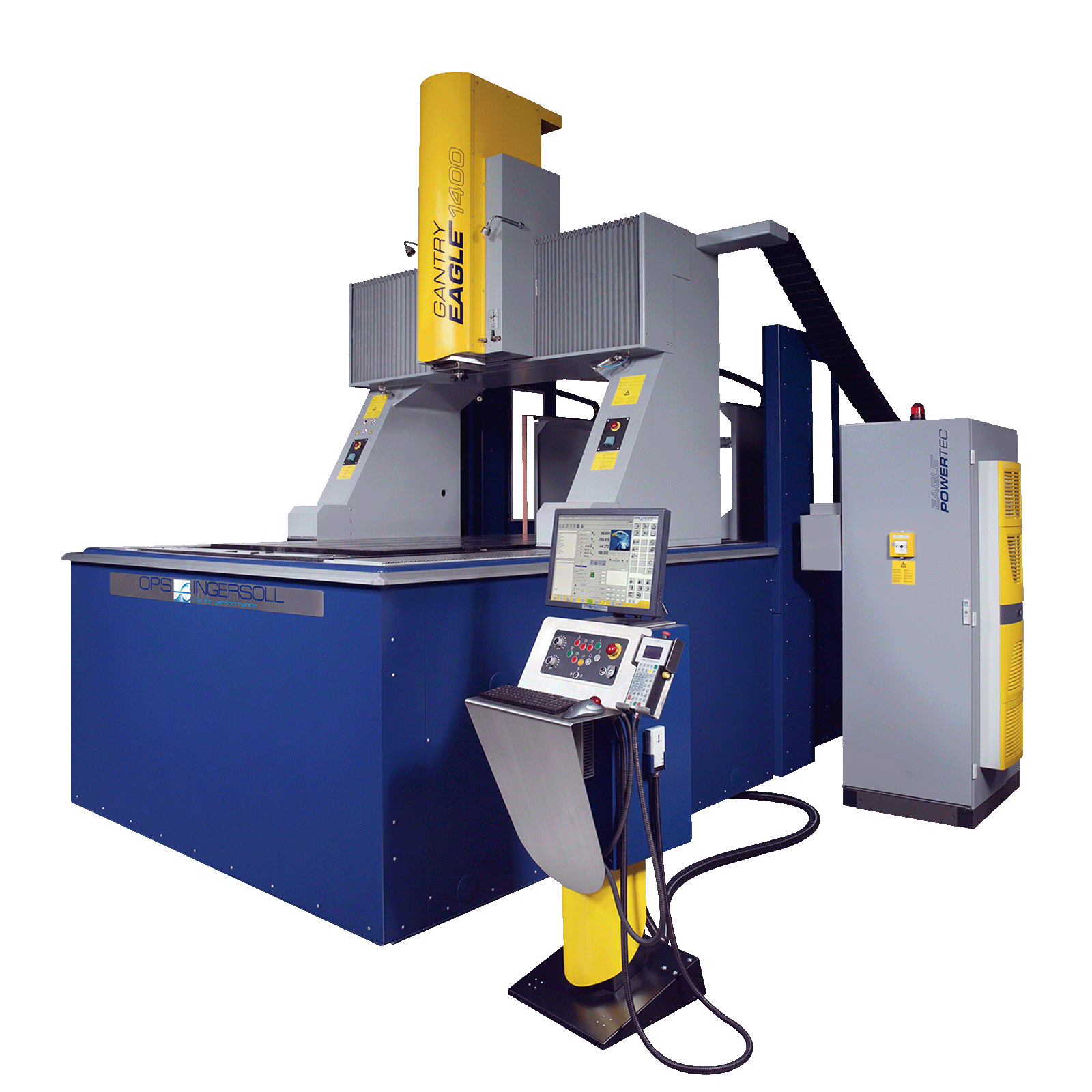

A true workhorse for all large mold shops – the best electrode wear and cycle times create an excellent ROI.

LEARN MORE

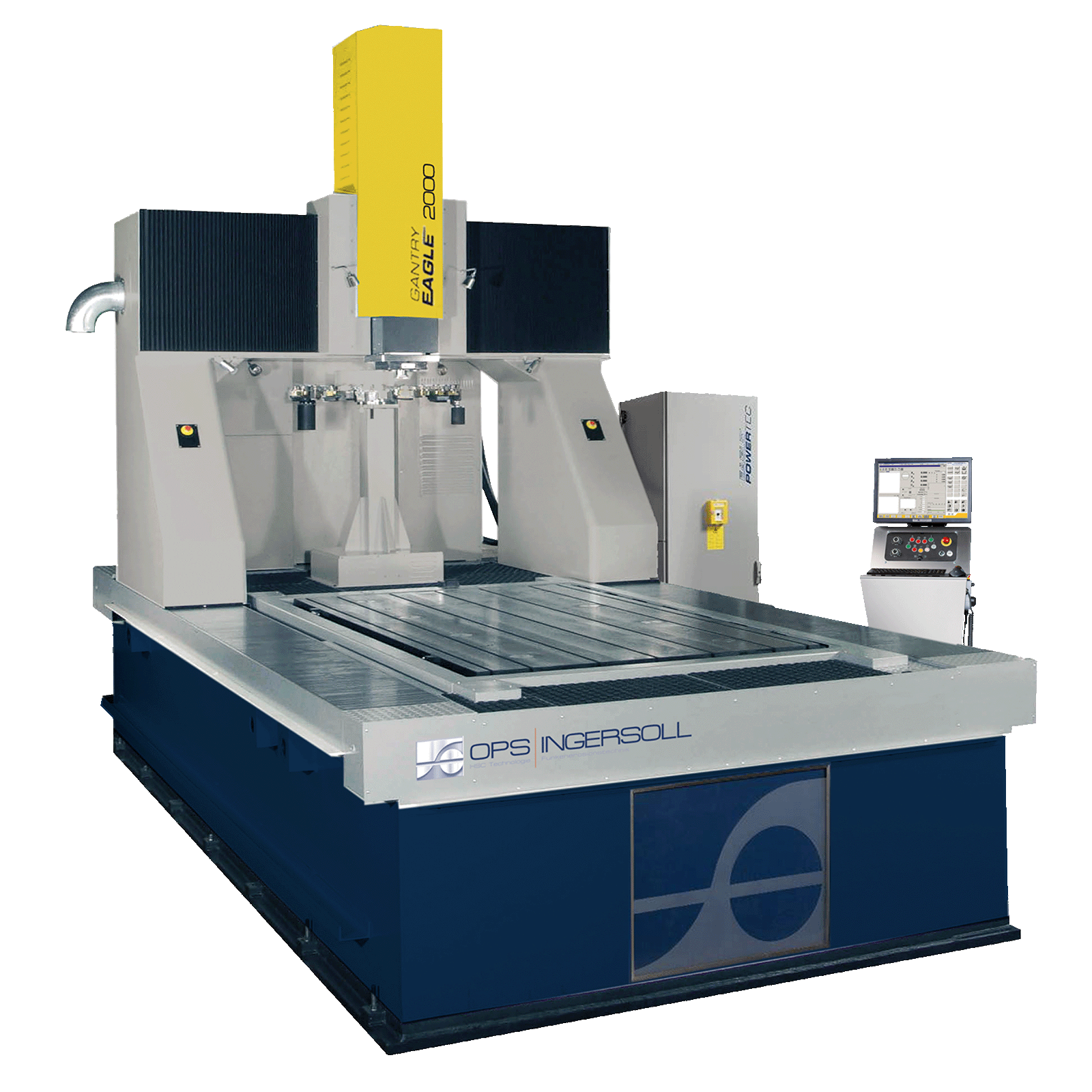

The largest Gantry Eagle machine available for challenges that require nothing but the best.

LEARN MORE

A cost-effective solution for medium to large size applications - combines machine performance and versatility.

LEARN MORE

A perfect solution for applications requiring ± .0001 tolerance and to produce a 4Ra finish (optional) – lowest cost of…

LEARN MORE

A perfect solution for applications requiring ± .0001 tolerance – with a larger tank capacity, and the lowest cost of…

LEARN MORE

Ideal for large part applications, up to 20” high (standard), and 32” high (optional) – with the lowest cost of…

LEARN MORE

Ideal for medium to large tall parts, up to 16.5” high – with the lowest cost of operation in the…

LEARN MORE

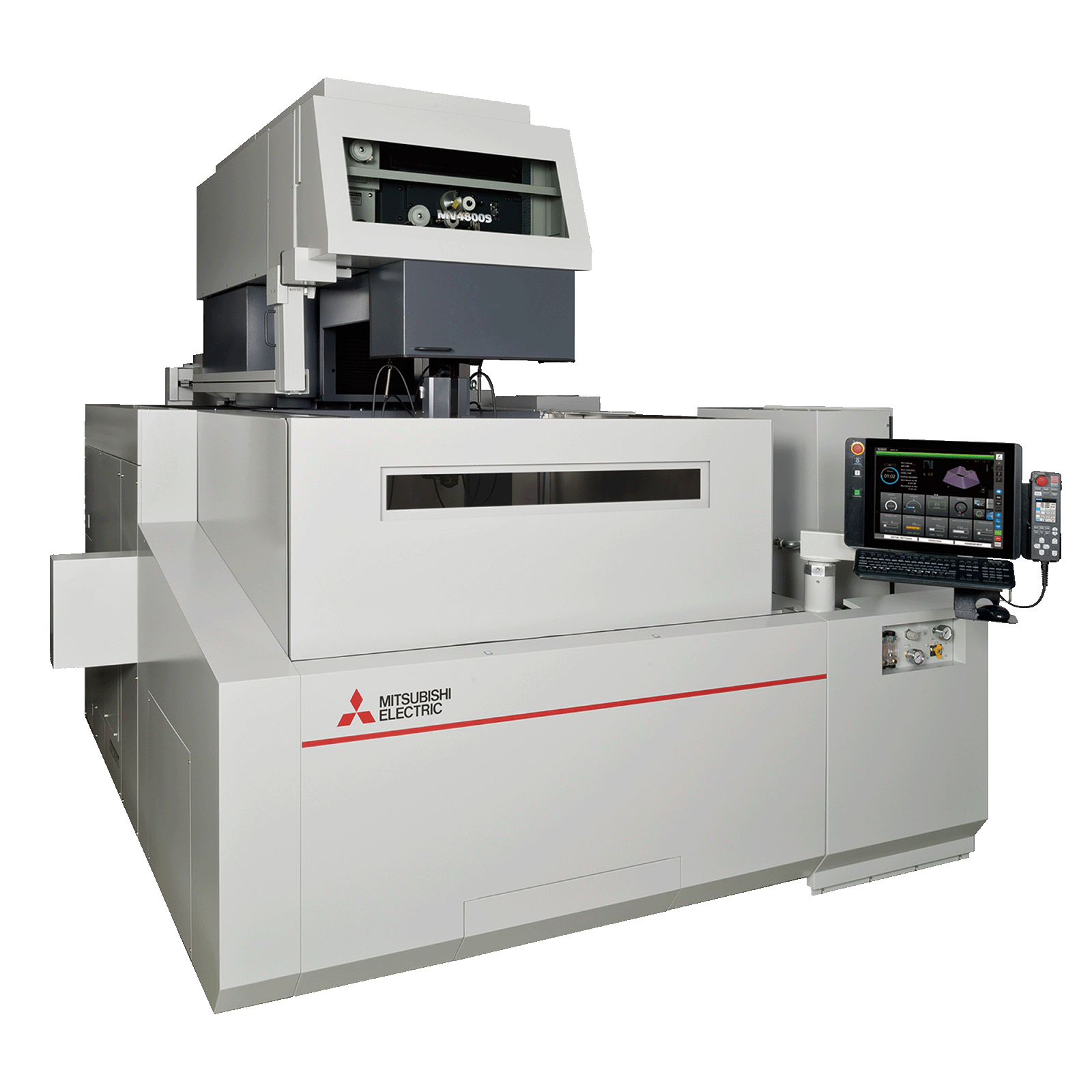

Combines the ultimate in machine accuracy and surface finish – Wire capability down to .0008” (.02mm) Dia.

LEARN MORE

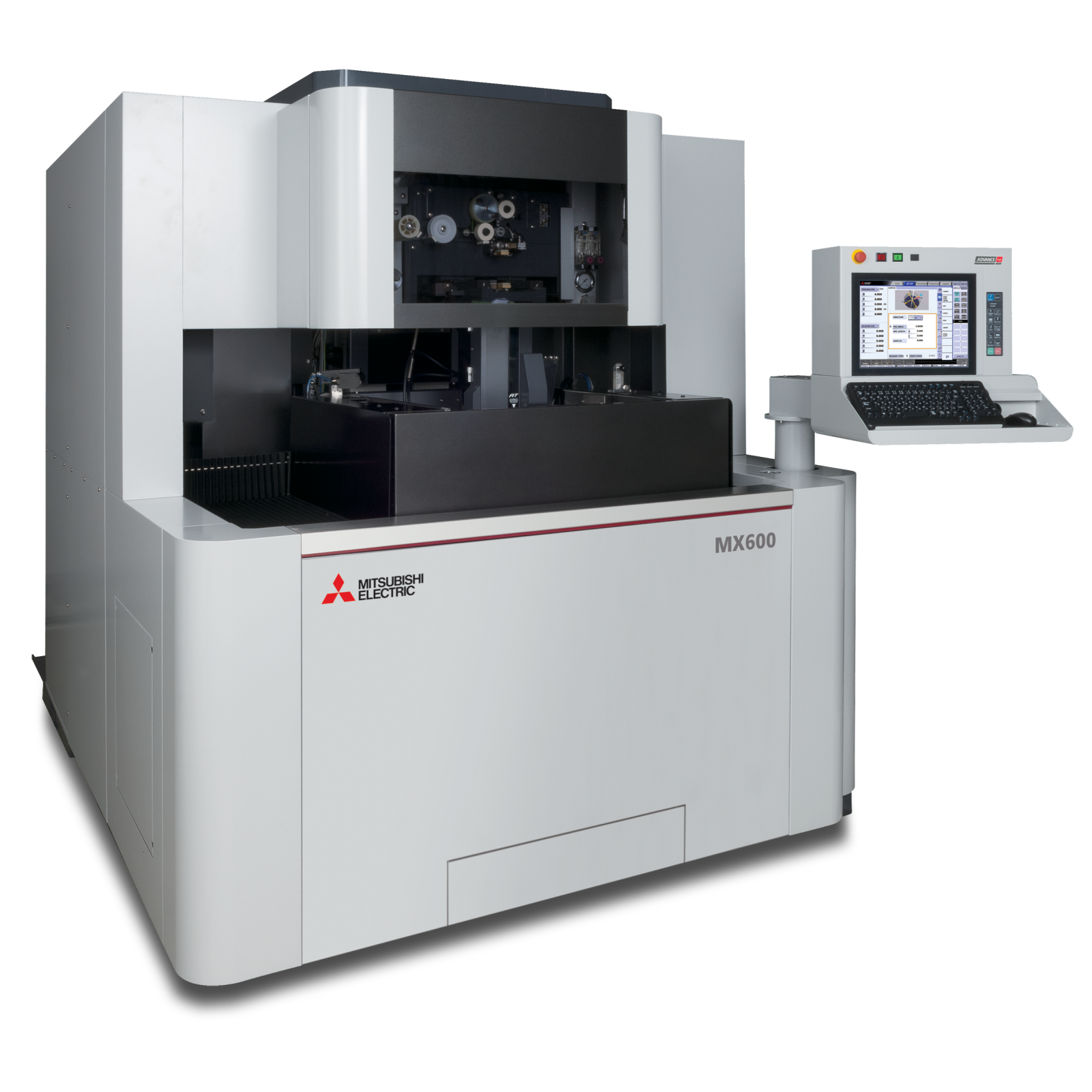

A cost effective solution for small/production applications - our #1 selling EDM.

LEARN MORE