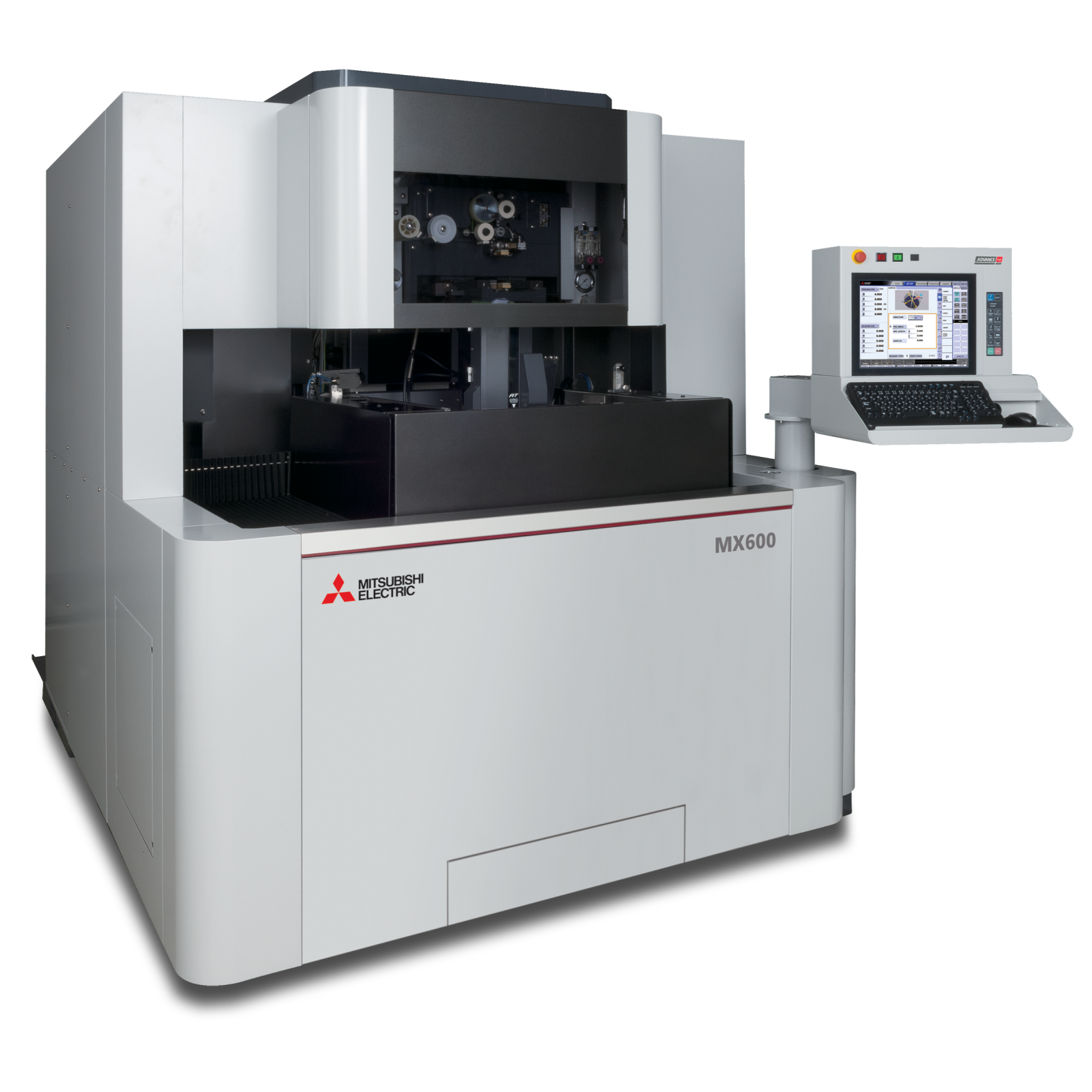

Combines the ultimate in machine accuracy and surface finish – Wire capability down to .0008” (.02mm) Dia.

LEARN MOREHigh speed and large capacity submerged Wire EDM, perfect for the die mold industry.

The FA40V Advance is one of the world’s fastest, large-workpiece, high-accuracy wire EDM machines. The FA40V Advance features the M700 series control with a 15-inch touchscreen, providing easy user interface. The new features available with the FA40V Advance exemplify Mitsubishi’s continued dedication to high-precision, innovative machining and are sure to advance your shop’s production.