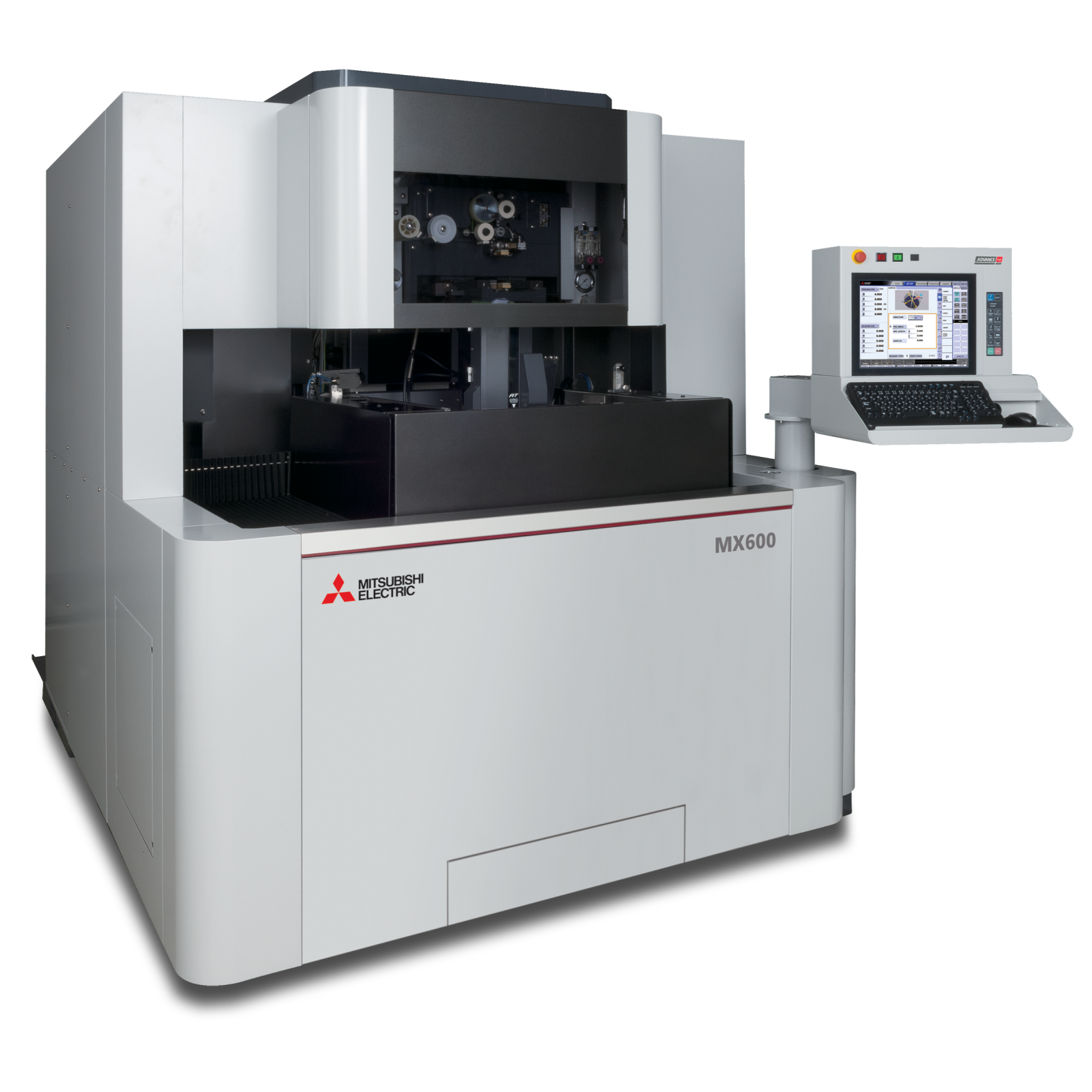

Combines the ultimate in machine accuracy and surface finish – Wire capability down to .0008” (.02mm) Dia.

LEARN MOREWhen it comes to razor-sharp precision on hardened materials, nothing beats a sinker EDM machine from MC Machinery Systems.

Advanced controls, on-board automation capabilities, and a superior power supply make our sinker EDM machines the ideal choice for tight-tolerance applications in industries including aerospace, energy, medical, and die/mold.

Sinker EDM machine technology from MC Machinery Systems offers unbeatable precision and reliability when and where you need it.

With EDM automation from MC Machinery Systems, customers can increase throughput and maximize their resources.

EDM automation cells may employ OPS Ingersoll five-axis or Roku-Roku high-speed vertical milling machines and robots to speed electrode production and replacement while allowing for complete lights-out operation. Our wire EDM automation solutions add the capacity to load and cut workpieces in immediate succession—loading and unloading them automatically.

A new world of increased throughput, cost efficiency, process optimization and more is waiting for you. Let’s get to work automating your production requirements today.